Assembly device for a sidelight light source module and liquid crystal panel

a technology of sidelight light source module and liquid crystal panel, which is applied in the direction of lighting and heating apparatus, planar/plate-like light guides, instruments, etc., can solve the problems of difficult control of the ratio of three colors and the manufacturing process, relative dull white light, and uniformity of mixed light, etc., to achieve superior color rendering and uniformity of transmitted backlight white light, easy control, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

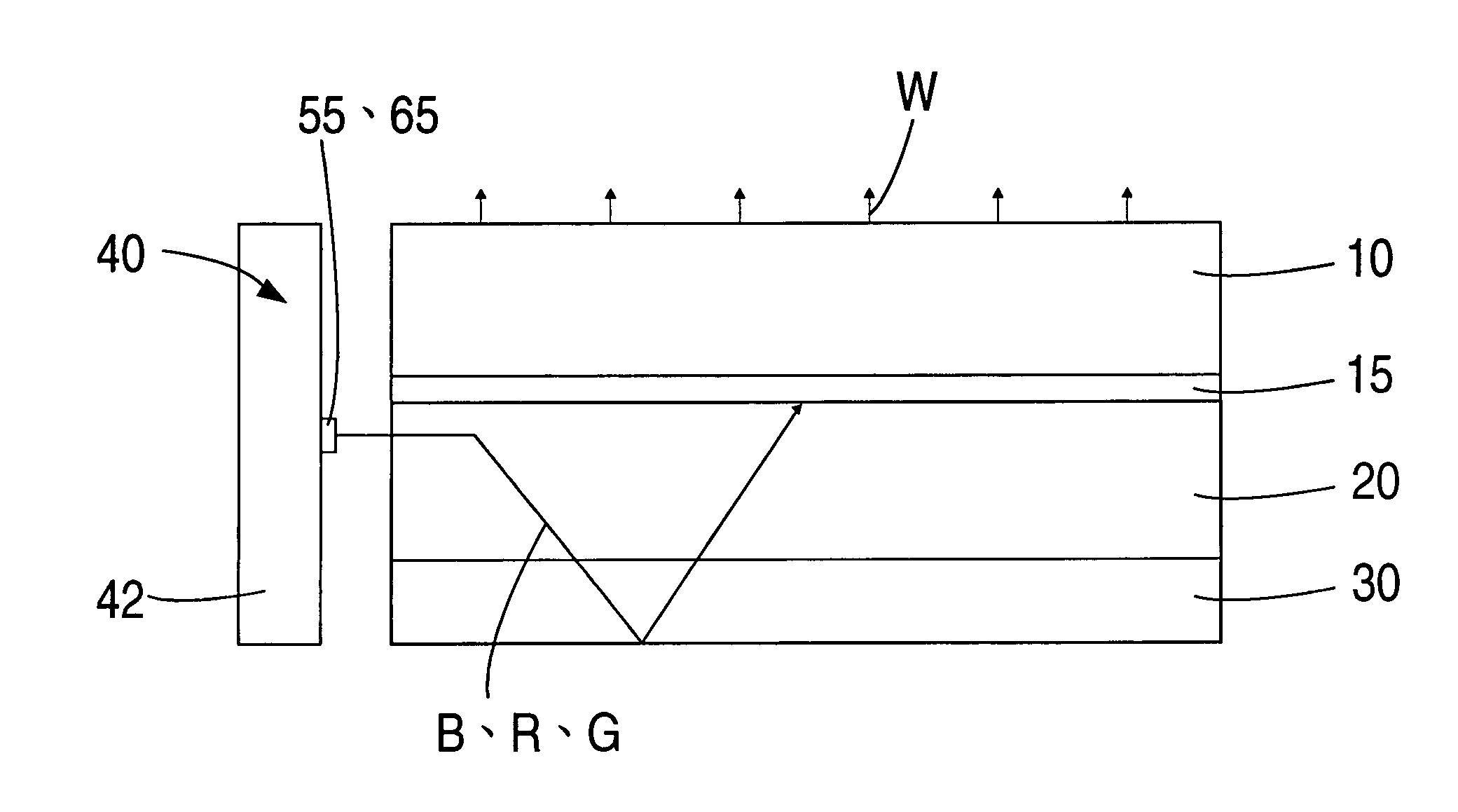

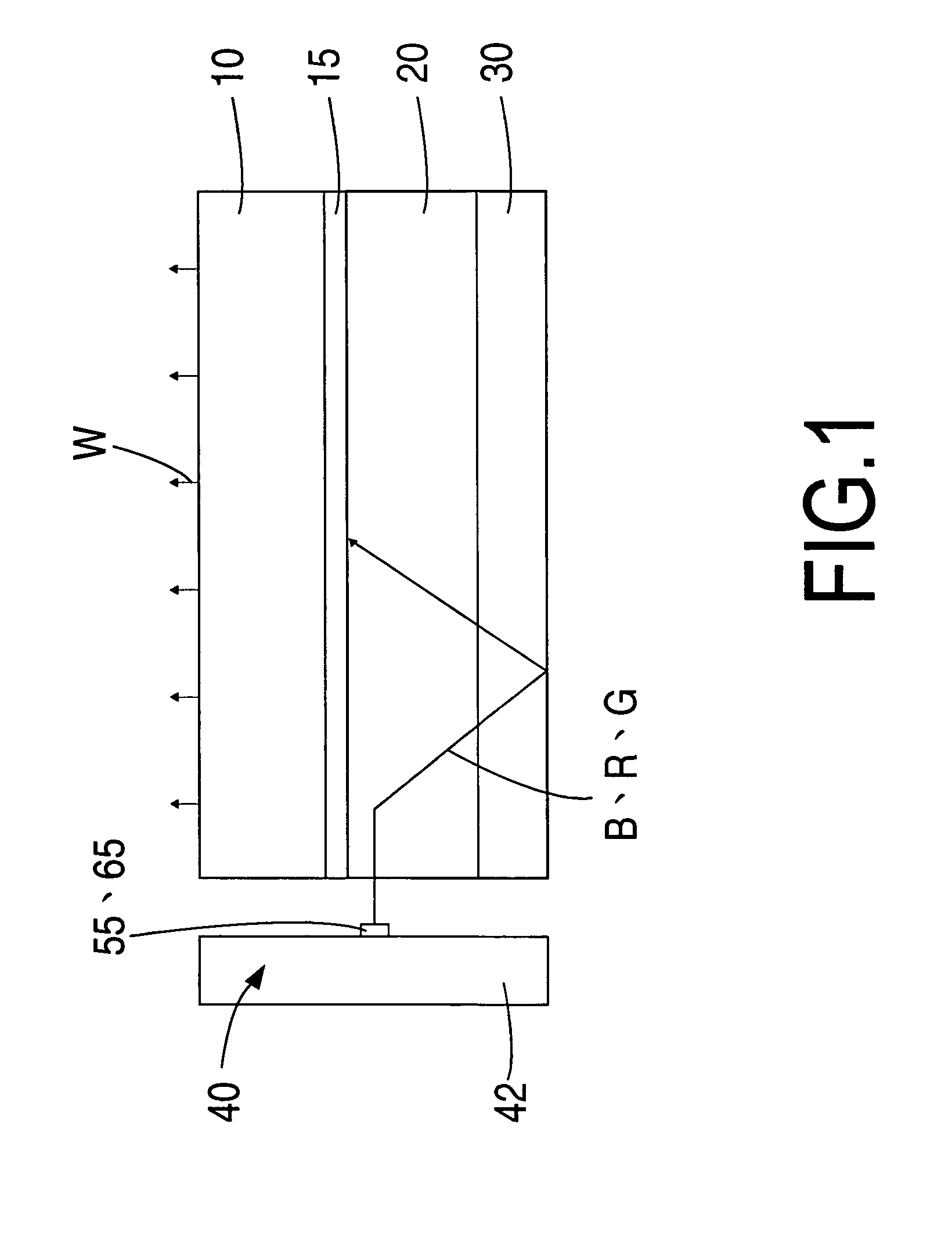

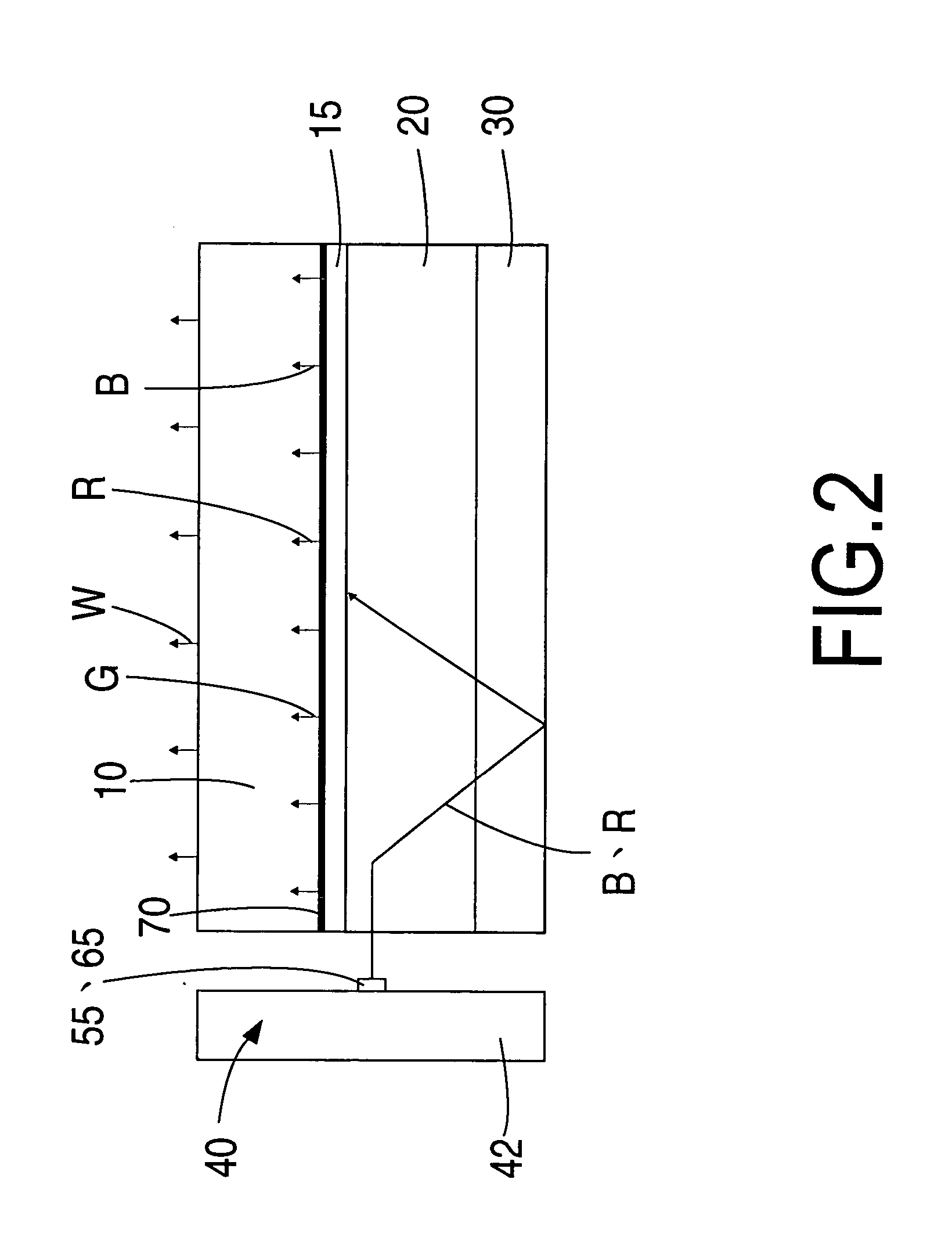

[0028] Referring to FIGS. 1 and 9, the assembly device for a sidelight light source module and liquid crystal panel of the present invention comprises:

[0029] a liquid crystal panel 10;

[0030] a light guide panel 20 positioned below the liquid crystal panel 10;

[0031] a light reflecting plate 30 positioned below the light guide panel 20;

[0032] a light source module 40 installed at a side of the light guide panel 20; wherein the light source module comprises:

[0033] a circuit board 42, on top of which is soldered at least more than one blue light chip 55 that serves as a blue light B light-emitting source and at least more than one red light chip 65 that serves as a red light R light-emitting source, wherein the blue light chips 55 and the red light chips 65 are reciprocally adjacent;

[0034] a luminescence fluorescent layer 70 is positioned on top of the blue light chip 55 and the red light chip 65, wherein the blue light B is primarily used to excite the fluorescent layer 70 and em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com