Printed circuit board using paste bump and manufacturing method thereof

a technology of printed circuit boards and bumps, which is applied in the direction of printed circuits, printed circuit details, printed elements, etc., can solve the problems of difficult micro-circuit formation, high cost, time-consuming, complicated plating process, etc., and achieves improved heat-releasing effect, improved connection reliability, and reduced lead times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

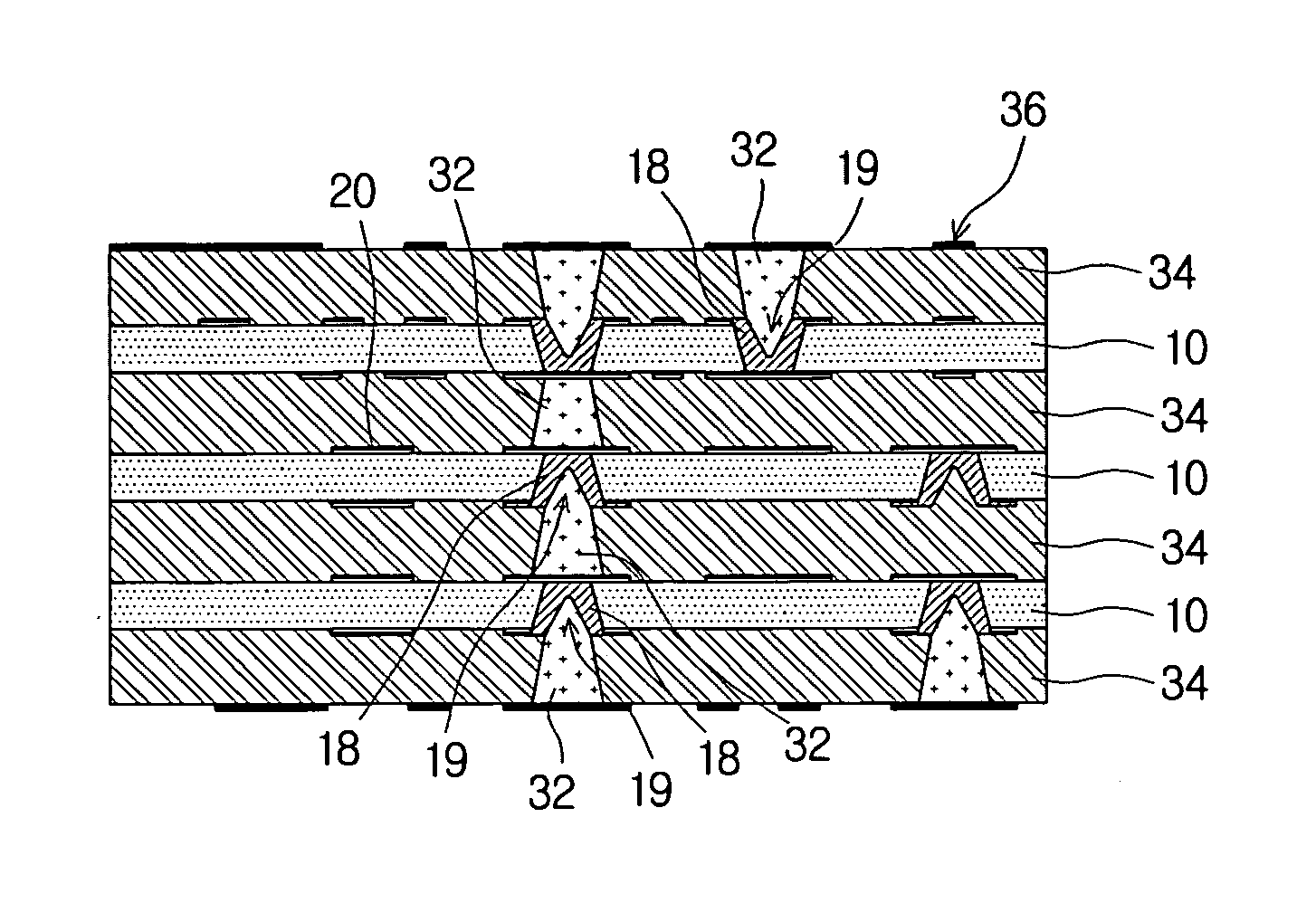

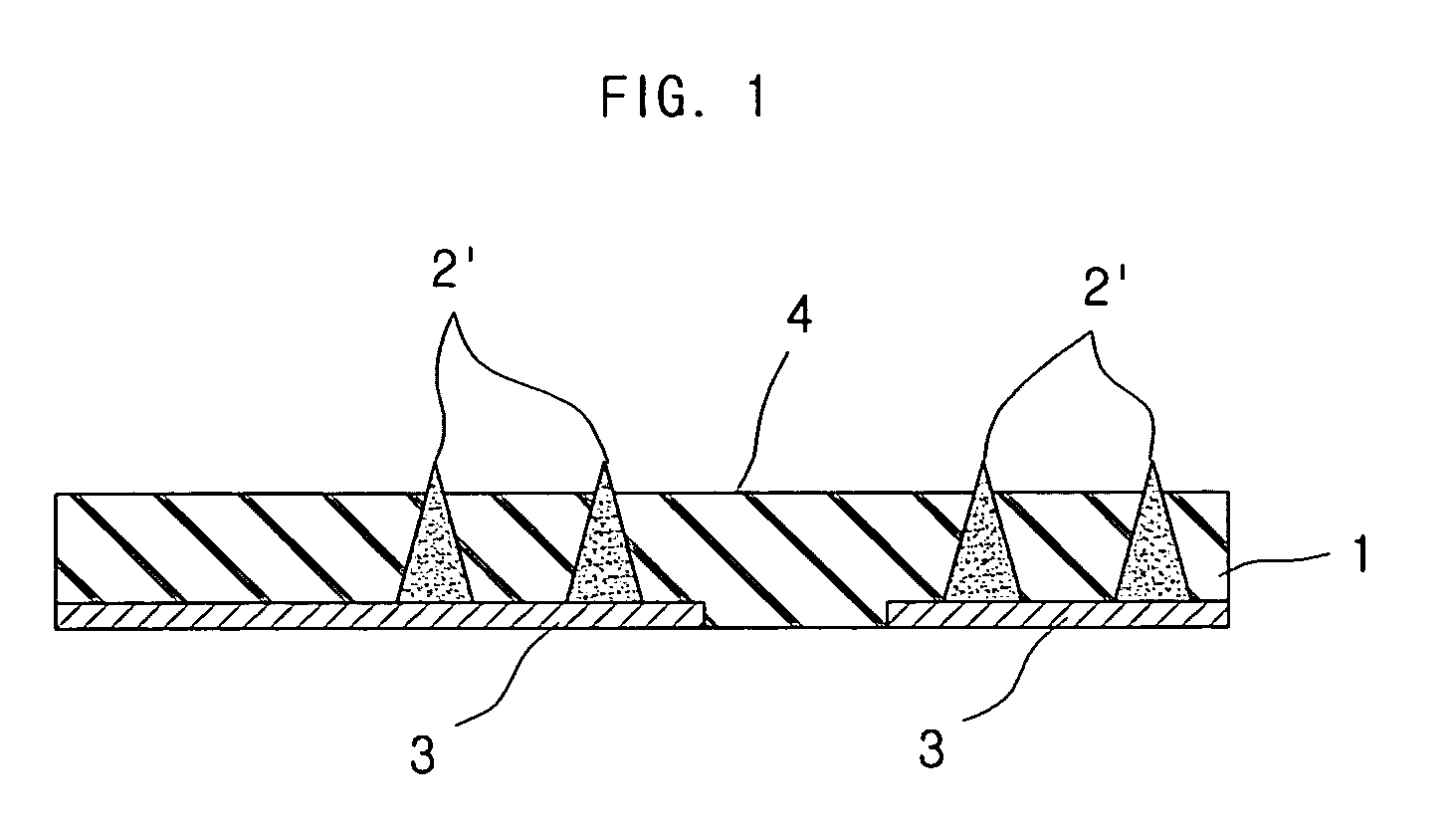

[0051] Embodiments of the printed circuit board using paste bumps and manufacturing method thereof, according to aspects of the invention, will be described below in more detail with reference to the accompanying drawings. In the description with reference to the accompanying drawings, those components are rendered the same reference number that are the same or are in correspondence regardless of the figure number, and redundant explanations are omitted.

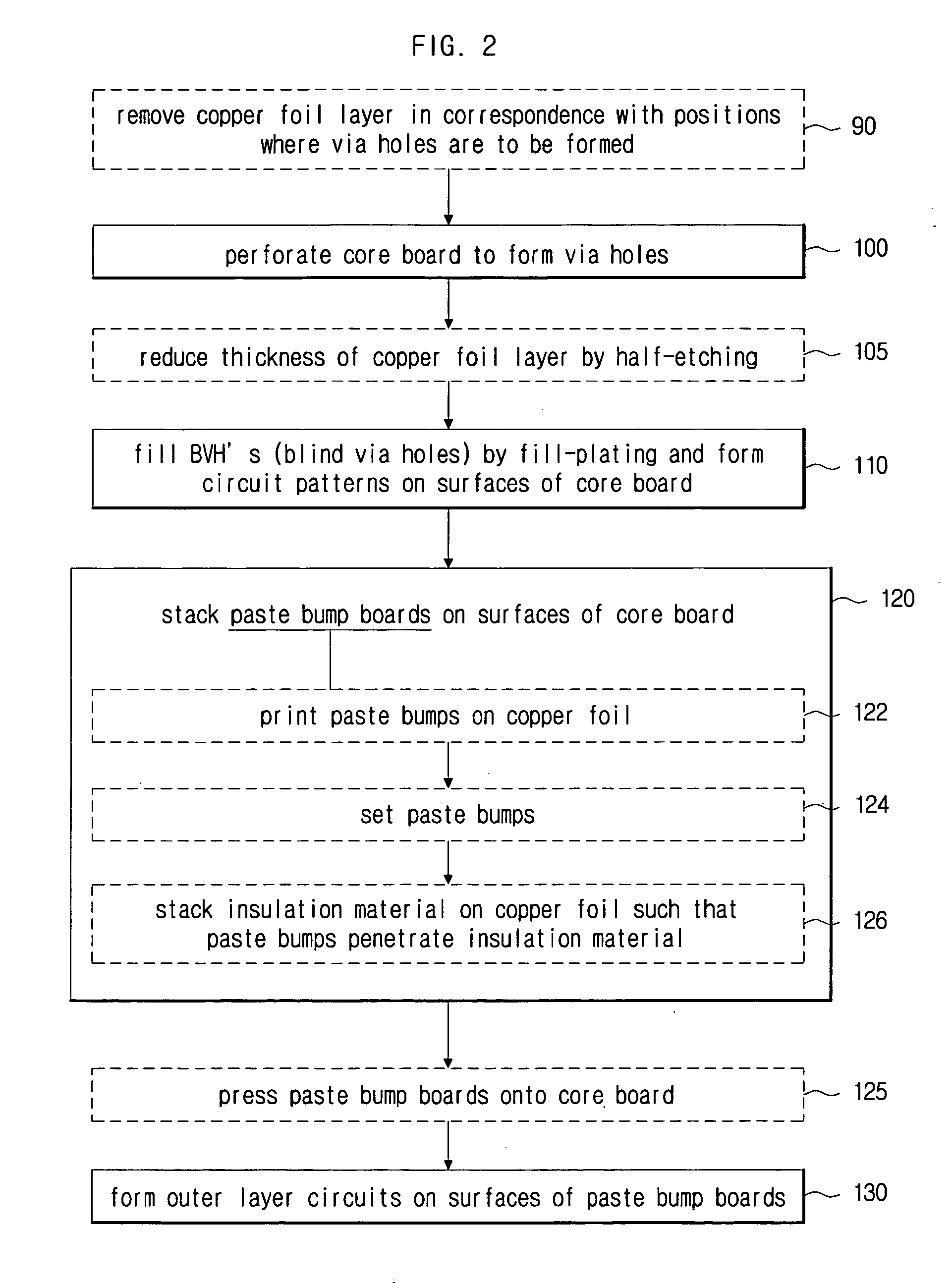

[0052]FIG. 2 is a flowchart illustrating a method of manufacturing a printed circuit board using paste bumps according to an embodiment of the present invention.

[0053] The present invention is for reducing the manufacture costs and times of a multilayer printed circuit board by collectively stacking paste bump boards on a core board, where a paste bump board is formed by performing plating on BVH's (blind via holes) formed in a core board, printing paste bumps on a copper foil in correspondence with the positions of the BVH's, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| electrically | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com