Method and system for constructing pre-fabricated building

a prefabricated and building technology, applied in the field of building construction, can solve the problems of insufficient connection between prefabricated panels, inefficient hvac systems, and major construction costs and quality of manufacture, and achieve the effects of reducing labor costs, reducing the restriction of air circulation caused by air return ducts, and reducing the temperature in the hom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In the present invention, the accepted method of building walls with stud type framework is retained. However, factory assembly apparatus and process control methods capable of maintaining dimensional quality control of pre-fabricated wall segments or panels have replaced on-site framing by carpenters.

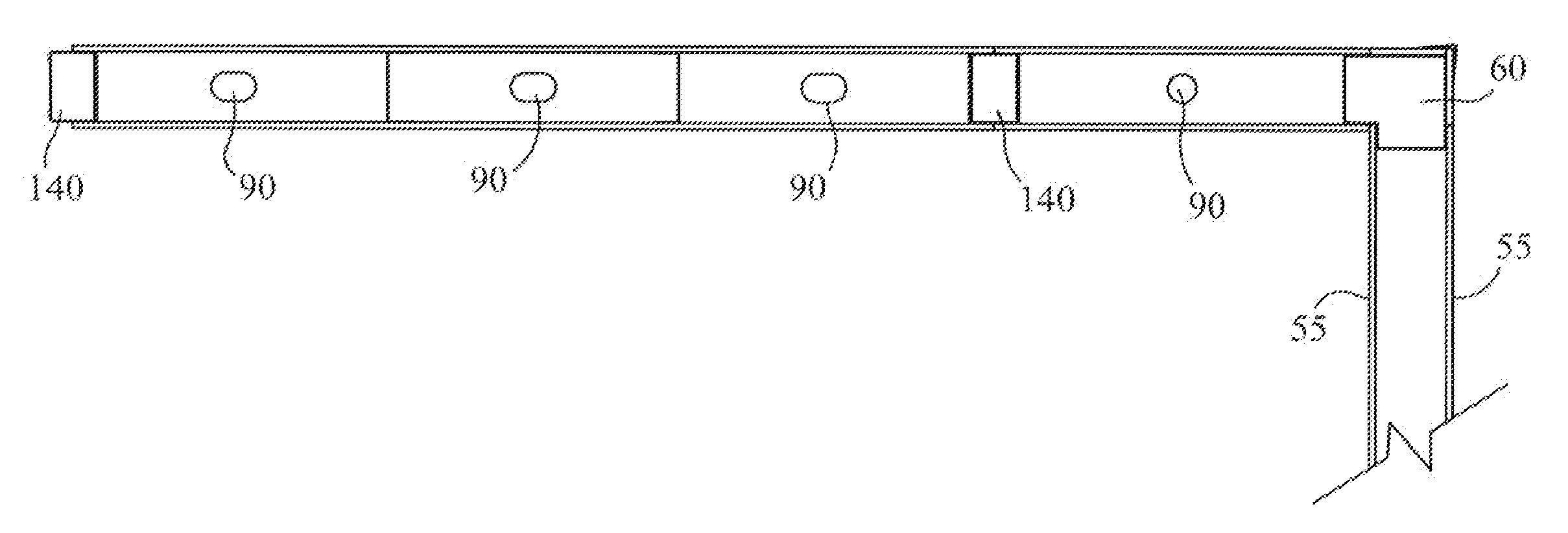

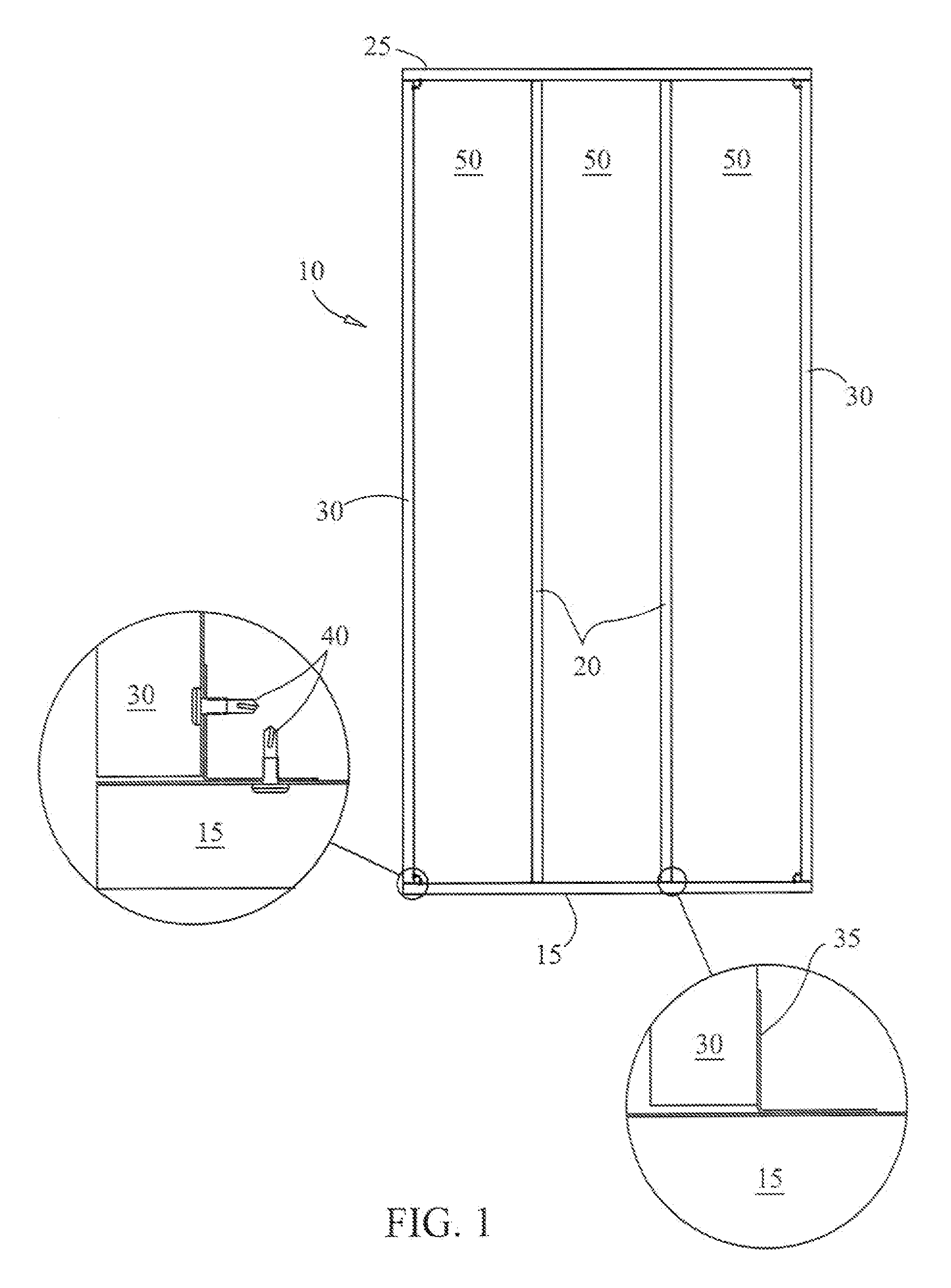

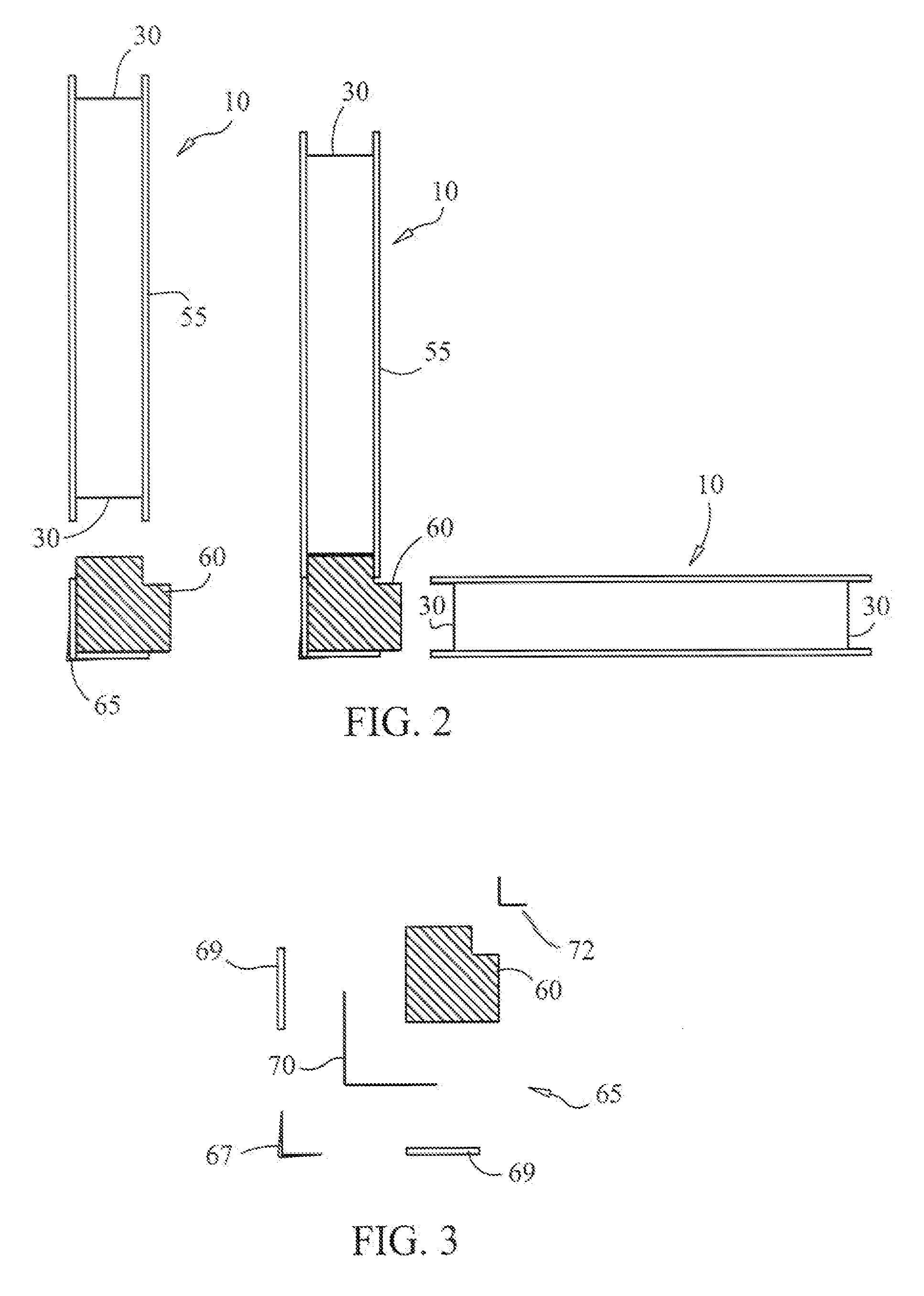

[0050] Referring now to FIG. 1, pre-fabricated wall panels 10 comprise a top plate 25 and bottom plate 15 including opposing end studs 30 to form the frame of wall panel 10. Intermediate studs 20 are interposed between ends studs 30. Foam inserts 50 are disposed within wall panel 10 and are adaptable to fit between the studs of wall panel 10. Foam inserts 50 provide support of wall panel 10 against inwardly directed force, insulation against heat transfer, vertical added load support, racking strength support, and integral chases for electrical wiring, plumbing piping and drains, HVAC duct placement, and specially system installations such as security, sound and computer. Screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com