MOS transistor with elevated source and drain structures and method of fabrication thereof

a technology of source and drain structure and mos transistor, which is applied in the direction of transistors, electrical devices, semiconductor devices, etc., can solve the problems of short channel effect, impact on switching performance, and general phenomenon of scaled-down mos transistor, and achieve the effect of increasing the effective channel length and limiting the diffusion of dopan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

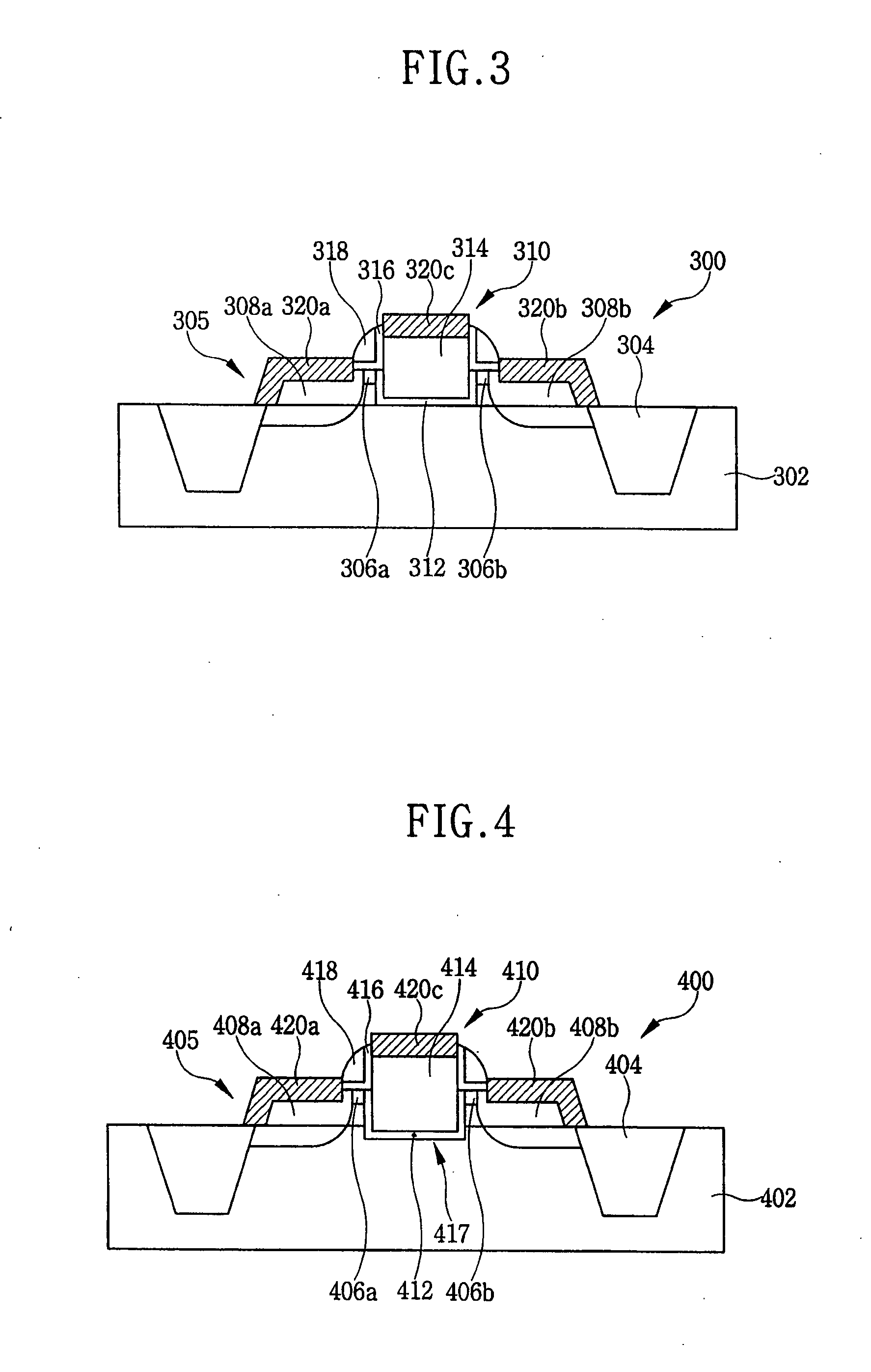

second embodiment

[0063] A second embodiment of the invention is shown and described above with reference to FIG. 4. In the second embodiment, the gate electrode 414 is formed in a trench or a recessed portion 417 of the semiconductor substrate 402. Other components of the transistor configuration of the second embodiment are similar to those of the first configuration above, and therefore their description will be omitted here. Components of FIG. 4 having a reference numeral beginning with the prefix “4” and a unique suffix “4xx” share the same purpose as those components of FIG. 3, described above, having the same suffix “3xx”.

[0064] A method of fabricating a semiconductor device according to the second embodiment of the present invention will now be described with reference to FIGS. 10A-10C.

[0065] The processes preceding the step shown at FIG. 10A are identical to those shown in FIGS. 9A-9D above with reference to the first embodiment.

[0066] Referring to FIG. 10A, the dummy gate, including the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com