Multi-zone carrier head for chemical mechanical polishing and CMP method thereof

a carrier head and mechanical polishing technology, applied in the direction of work carriers, automatic grinding control, metal-working devices, etc., can solve the problems of non-uniformity of removal rate across patterns of different densities, high topography of in-process wafers, and conventional cmp suffer from some problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

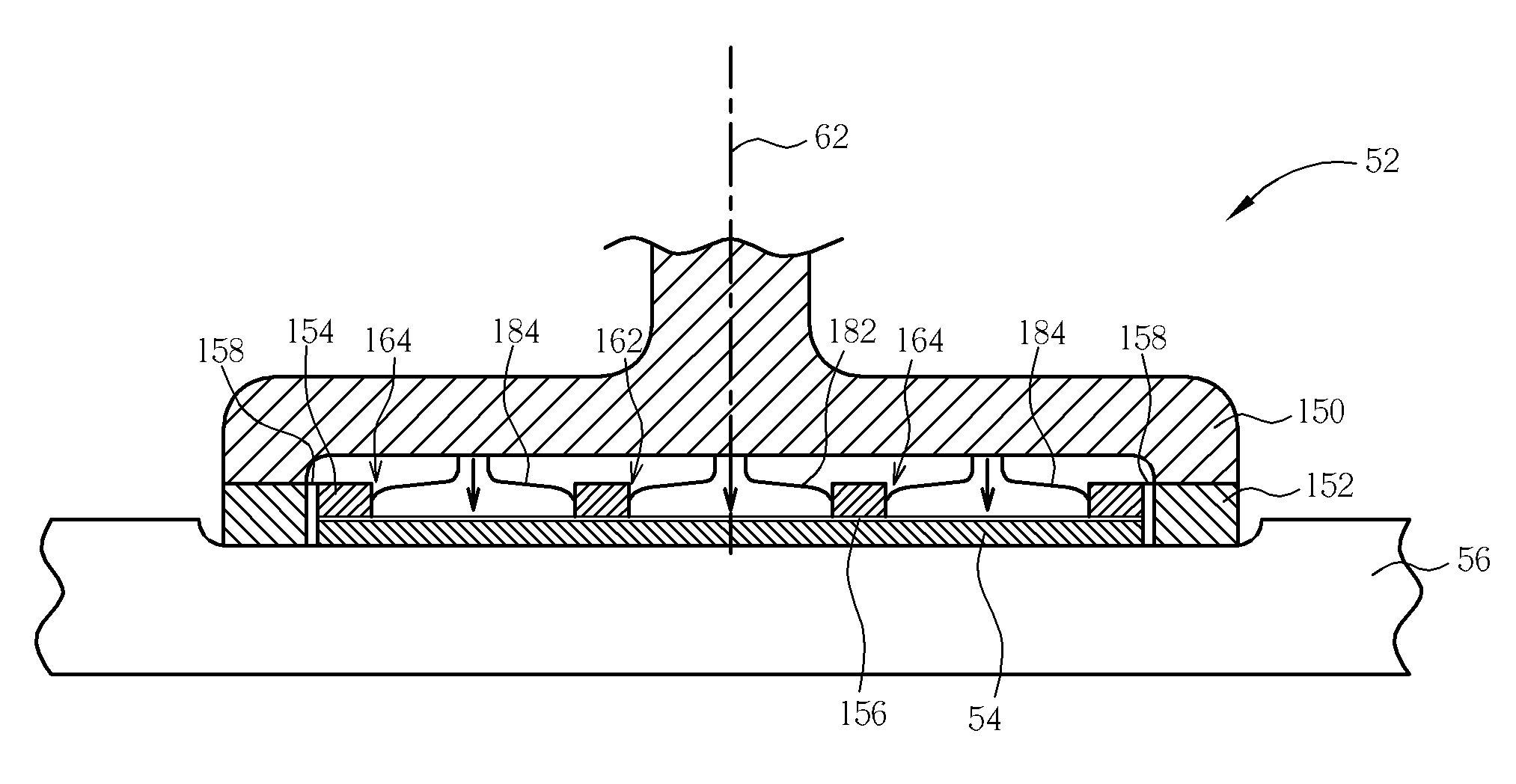

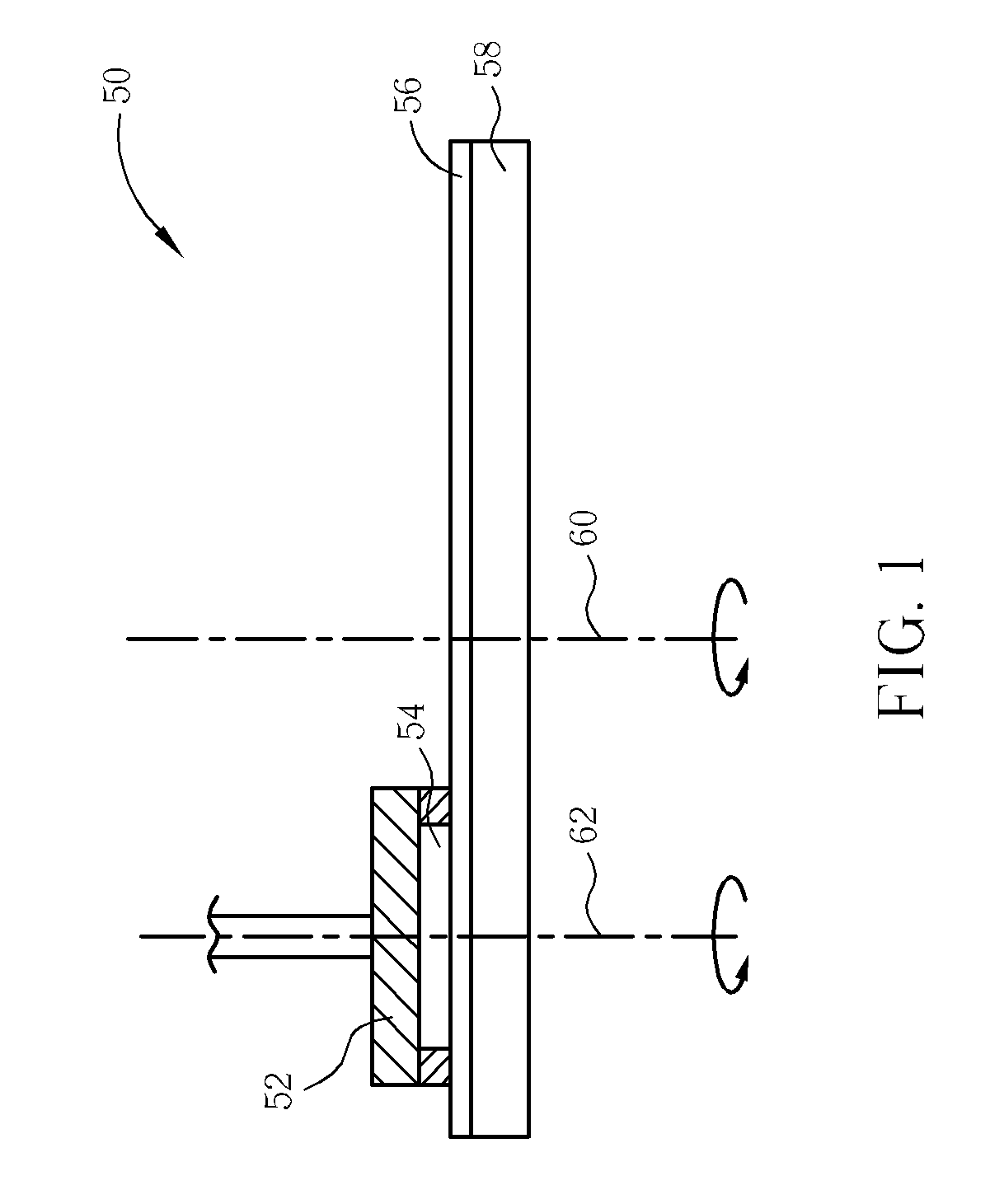

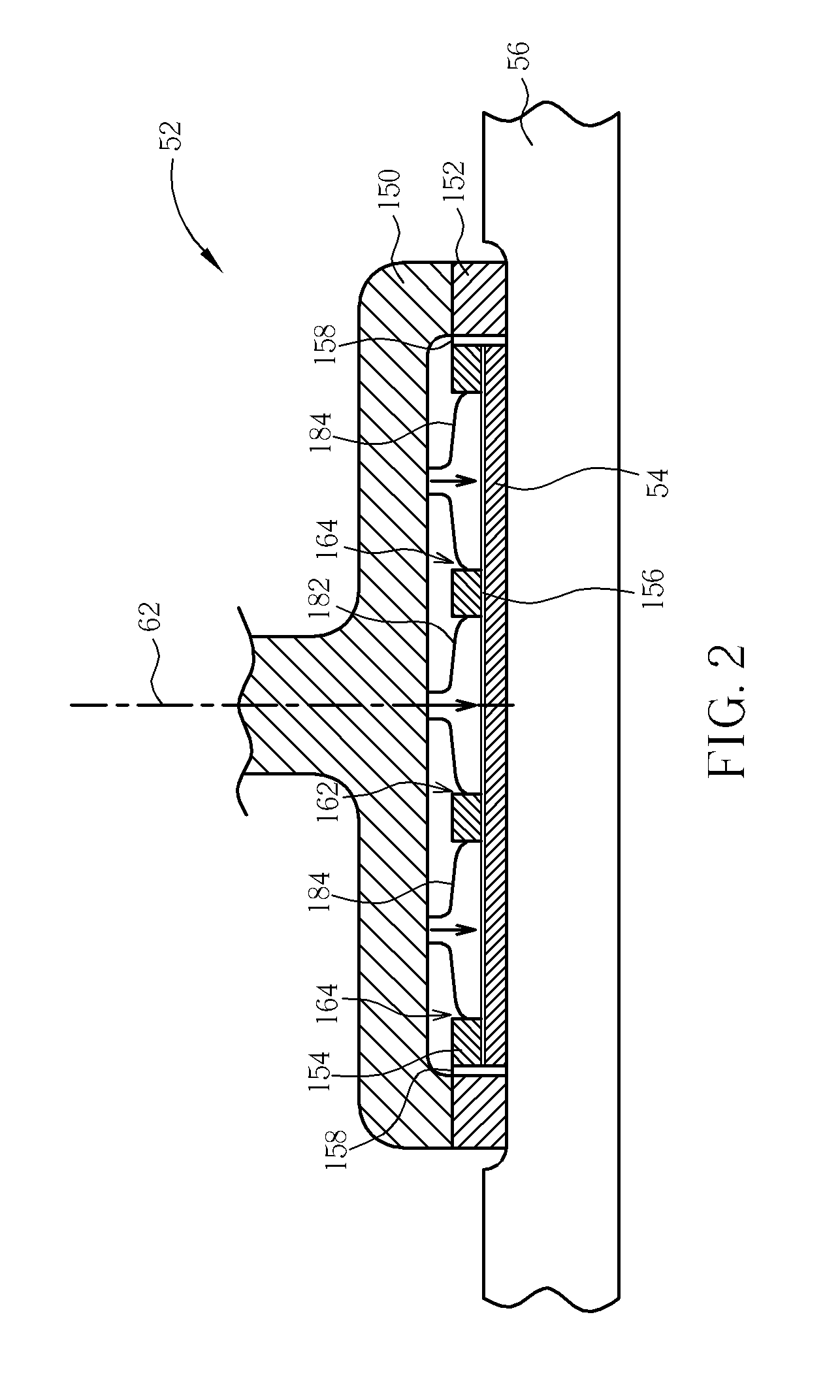

[0020]FIG. 1 is a diagram showing a table based CMP tool 50. The table based CMP tool 50 includes a carrier head 52, which holds a wafer 54, and is attached to a translation arm. In addition, the table based CMP tool 50 includes a polishing pad 56 that is disposed above a polishing table 58, which is often referred to as a polishing platen.

[0021] In operation, the carrier head 52 applies downward force to the wafer 54, which contacts the polishing pad 56. Reactive force is provided by the polishing table 58, which resists the downward force applied by the carrier head 52. A polishing pad 56 is used in conjunction with slurry to polish the wafer 54. Typically, the polishing pad 56 comprises foamed polyurethane or a sheet of polyurethane having a grooved surface. The polishing pad 56 is wetted with polishing slurry having both an abrasive and other polishing chemicals. In addition, the polishing table 58 is rotated about its central axis 60, and the carrier head 52 is rotated about i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com