Apparatus and method for providing fluid for immersion lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

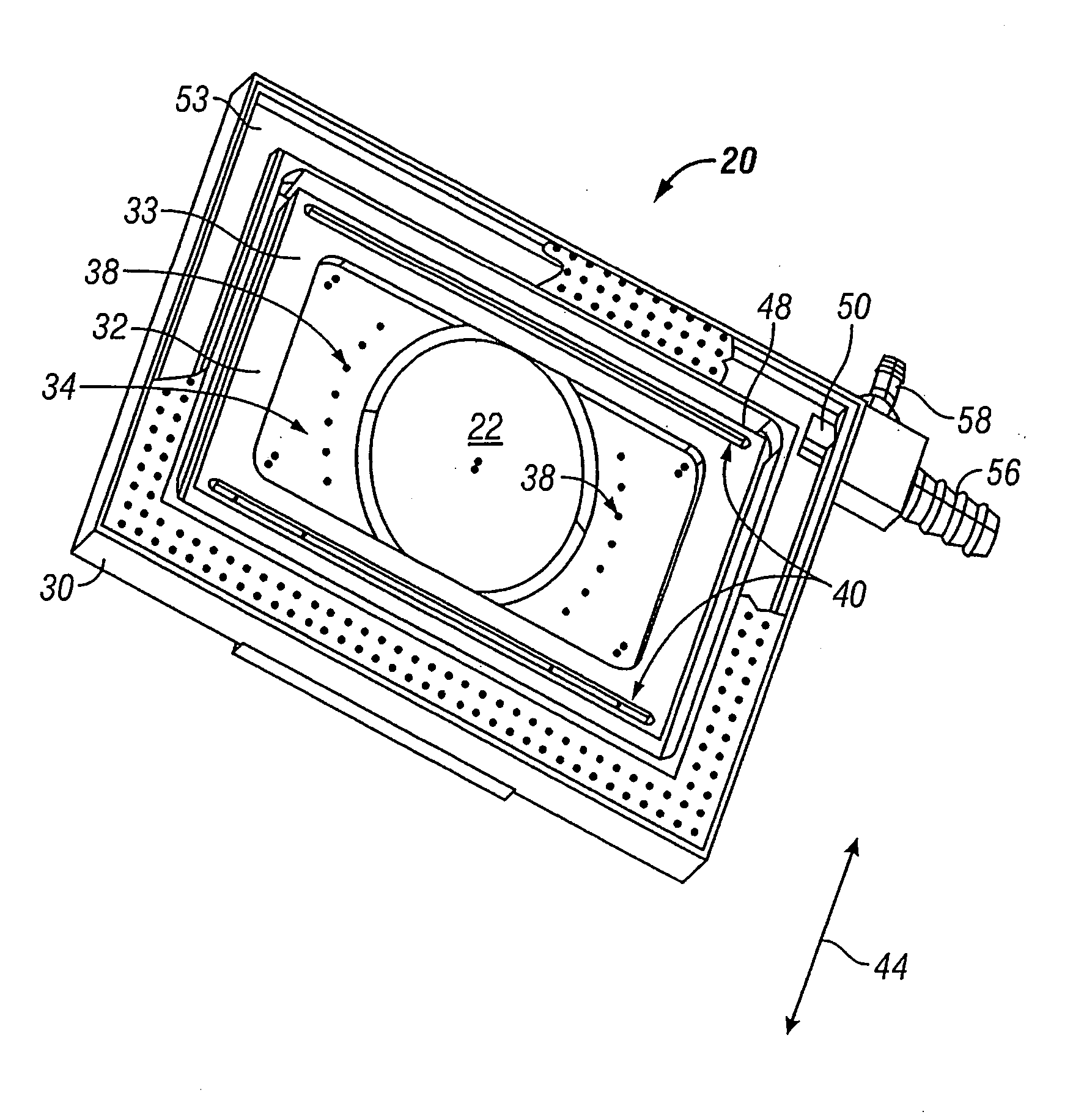

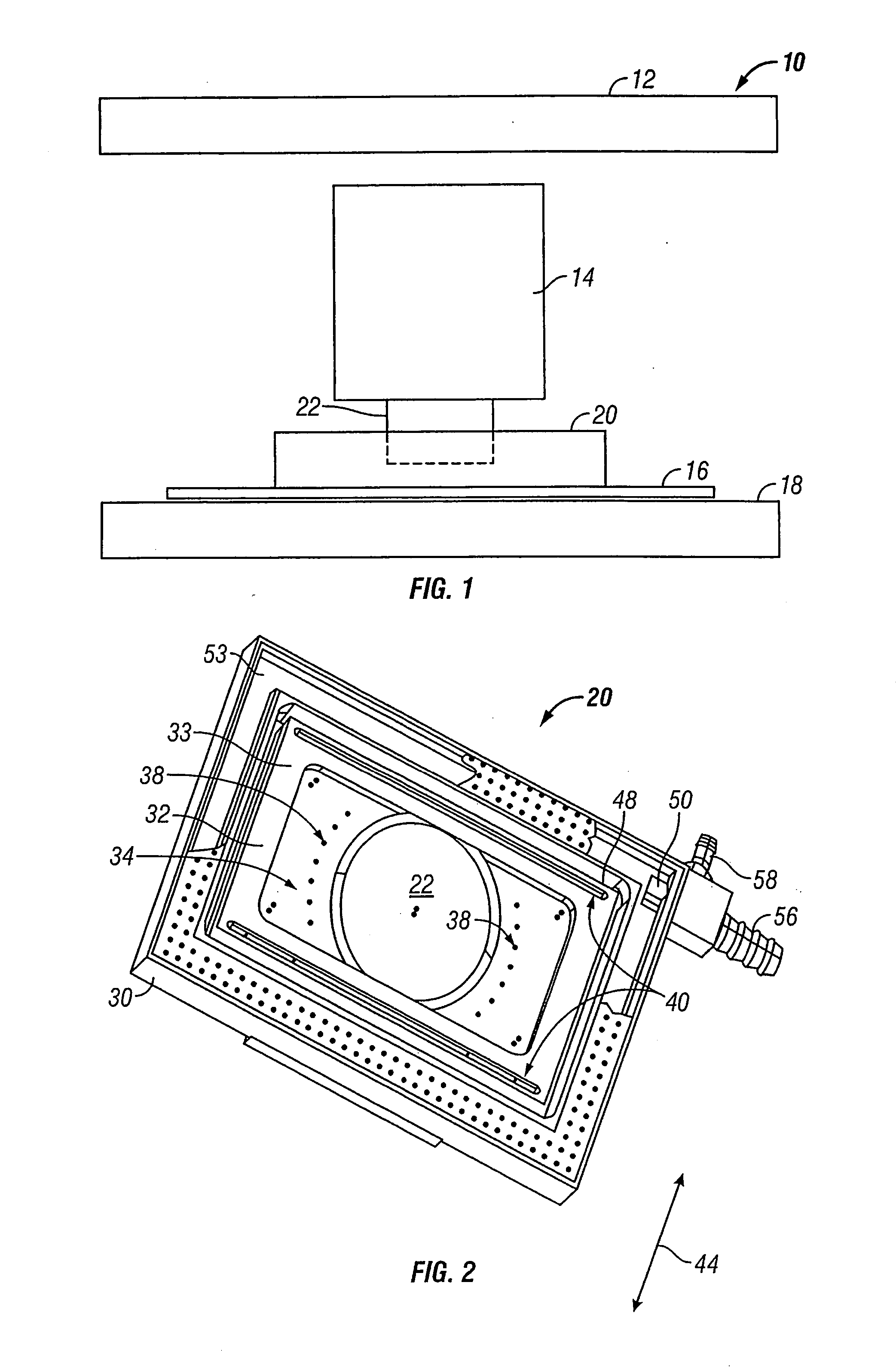

[0023]FIG. 1 shows an immersion lithography system 10 including a reticle stage 12 on which a reticle is supported, a projection lens 14, and a wafer 16 supported on a wafer stage 18. An immersion apparatus 20, which is sometimes referred to herein as a showerhead or a nozzle, is disposed around the final optical element 22 of the projection lens 14 to provide and recover a fluid, which may be a liquid such as water or a gas, between the final optical element 22 and the wafer 16. In the present embodiment, the immersion lithography system 10 is a scanning lithography system in which the reticle and the wafer 16 are moved synchronously in respective scanning directions during a scanning exposure.

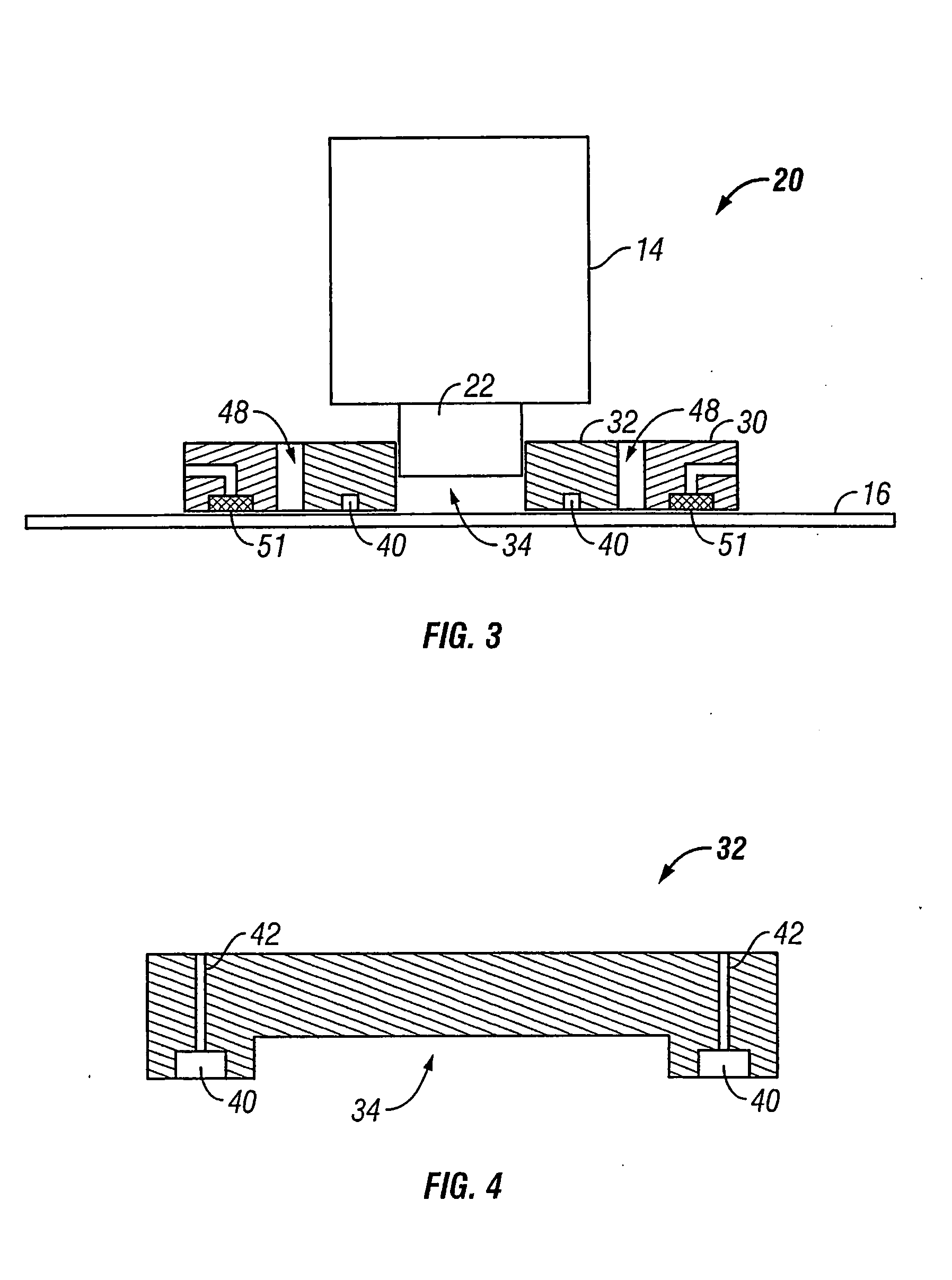

[0024]FIGS. 2 and 3 show the apparatus or nozzle 20 for delivery and recovery of the fluid between the final optical element 22 and the wafer 16 for immersion lithography. FIG. 2 shows the bottom perspective view of the nozzle 20, which includes an outer part 30 and an inner part 32. The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com