Decanter stopper with a vacuum pressure indicator

a vacuum pressure indicator and stopper technology, applied in the field of wine systems and methods, can solve the problems of wine deterioration, off-flavor of unconsumed wine, and the quality of non-carbonated soft drinks may deteriora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following description of the various embodiments of the present invention, reference is made to the accompanying drawings that form a part hereof, and in which is shown by way of illustration various embodiments of the present invention. It is to be understood that the scope of the present invention is not limited by the following description and by the accompanying drawings.

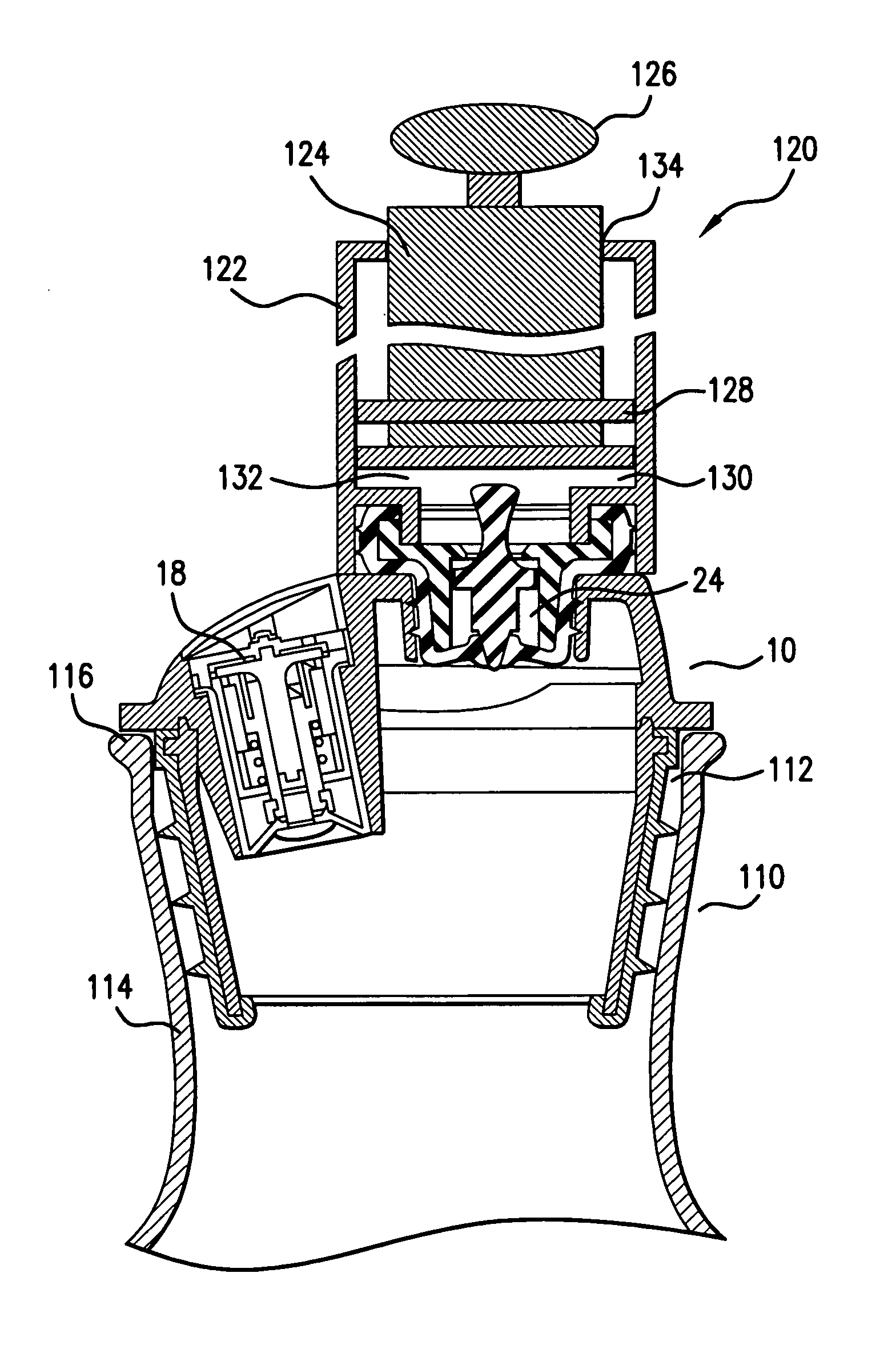

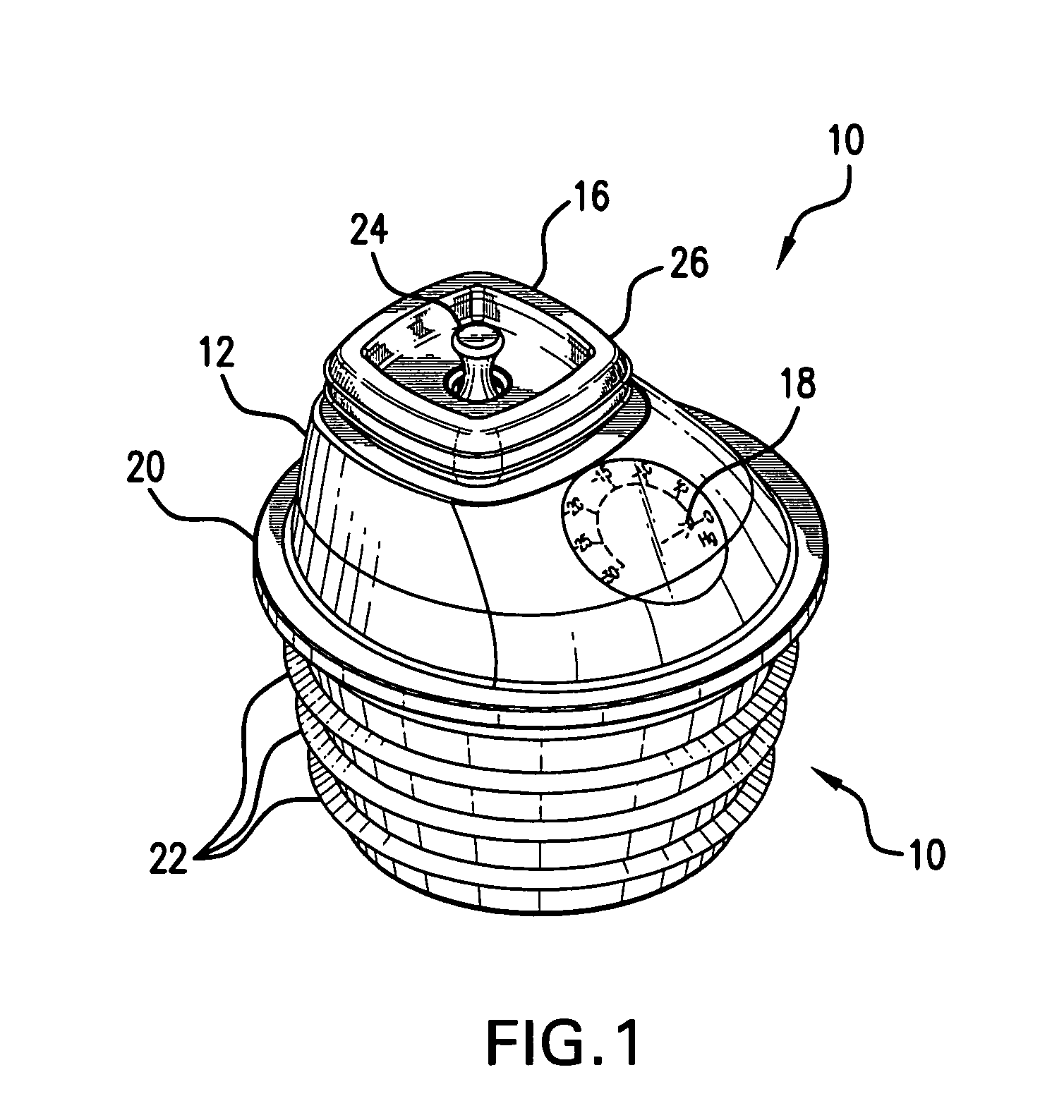

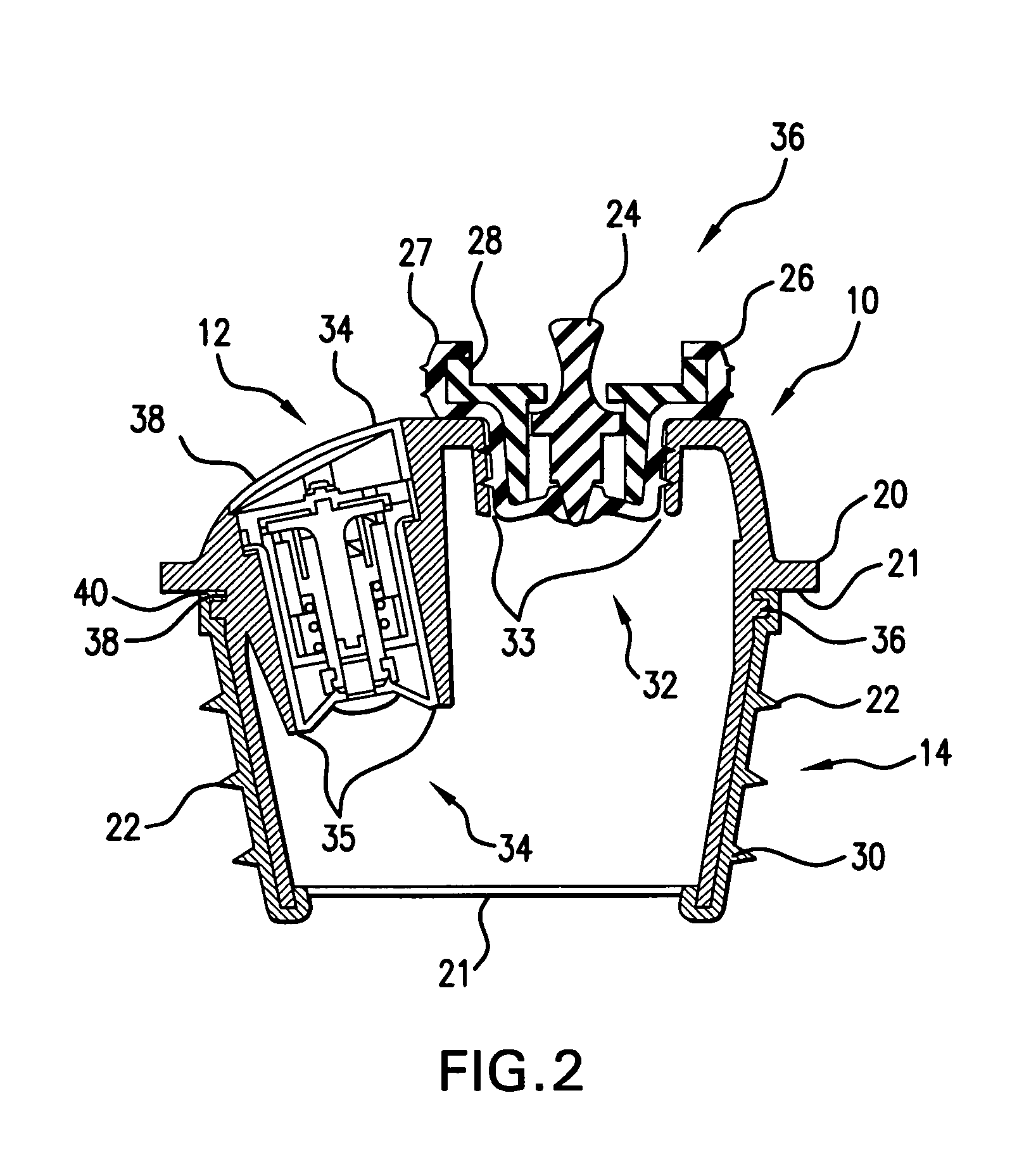

[0022]FIGS. 1 and 2 illustrate an elevated and section views, respectively, of a stopper for a decanter in accordance with an exemplary embodiment the present invention. The stopper 10 comprises a one-piece, integral, cylindrical body having an upper enclosed portion 12 and lower portion 14, which may be defined by a circumferential flange 20 extending radially outward. The enclosed upper portion 12 of the stopper 10 may comprise a semi-spherical body having two openings 32 and 34. The lower portion 14 is adapted to be inserted into the mouth 112 of the decanter 110 and thus may have an outside di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com