Methods and apparatuses for homogenizing light

a technology of light and homogenizer, applied in the field of optics, can solve the problems of increasing the complexity of the system, affecting the efficiency of the system, and the difficulty of creating simple and cost-effective high aspect ratio homogenized fields of illumination by prior art devices, etc., and achieves the effect of cost-effective and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

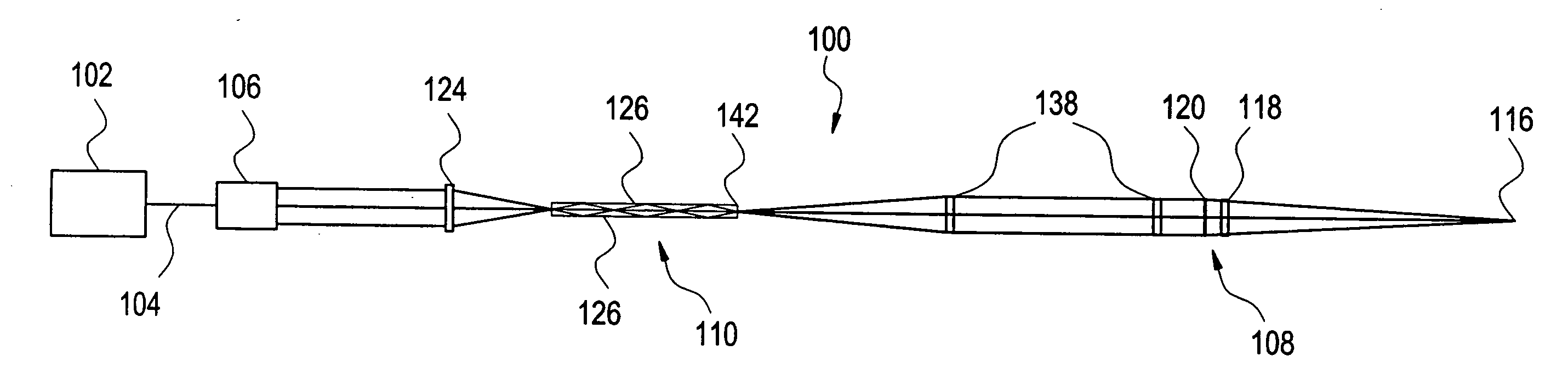

[0036] One purpose of the present invention is to generate, for example, a long rectangular laser illumination field homogenized both in a long (wide) direction (d1) and in a short (narrow) direction (d2), wherein (d1):(d2) is at least 5:1 (for example). Accordingly, some embodiments of the invention include an apparatus that synthesizes concepts from kaleidoscope and fly's eye homogenizer techniques to produce such a homogenized field. For example, in some embodiments, a one-dimensional fly's eye homogenizer is used to homogenize the laser beam in the long direction (d1) of the rectangular field and a one-dimensional kaleidoscope homogenizer is used to homogenize the beam in the short direction (d2) of the rectangular field.

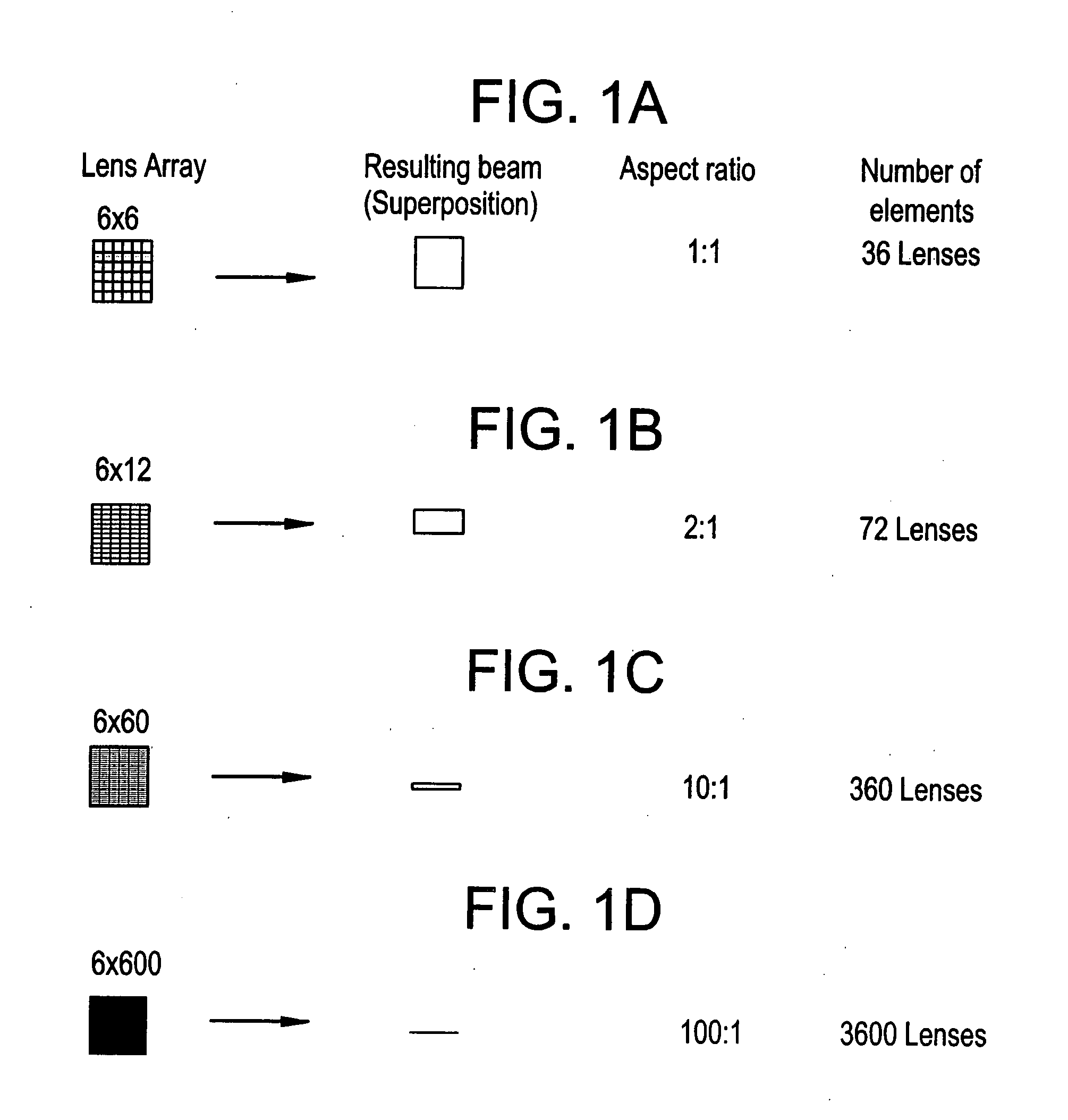

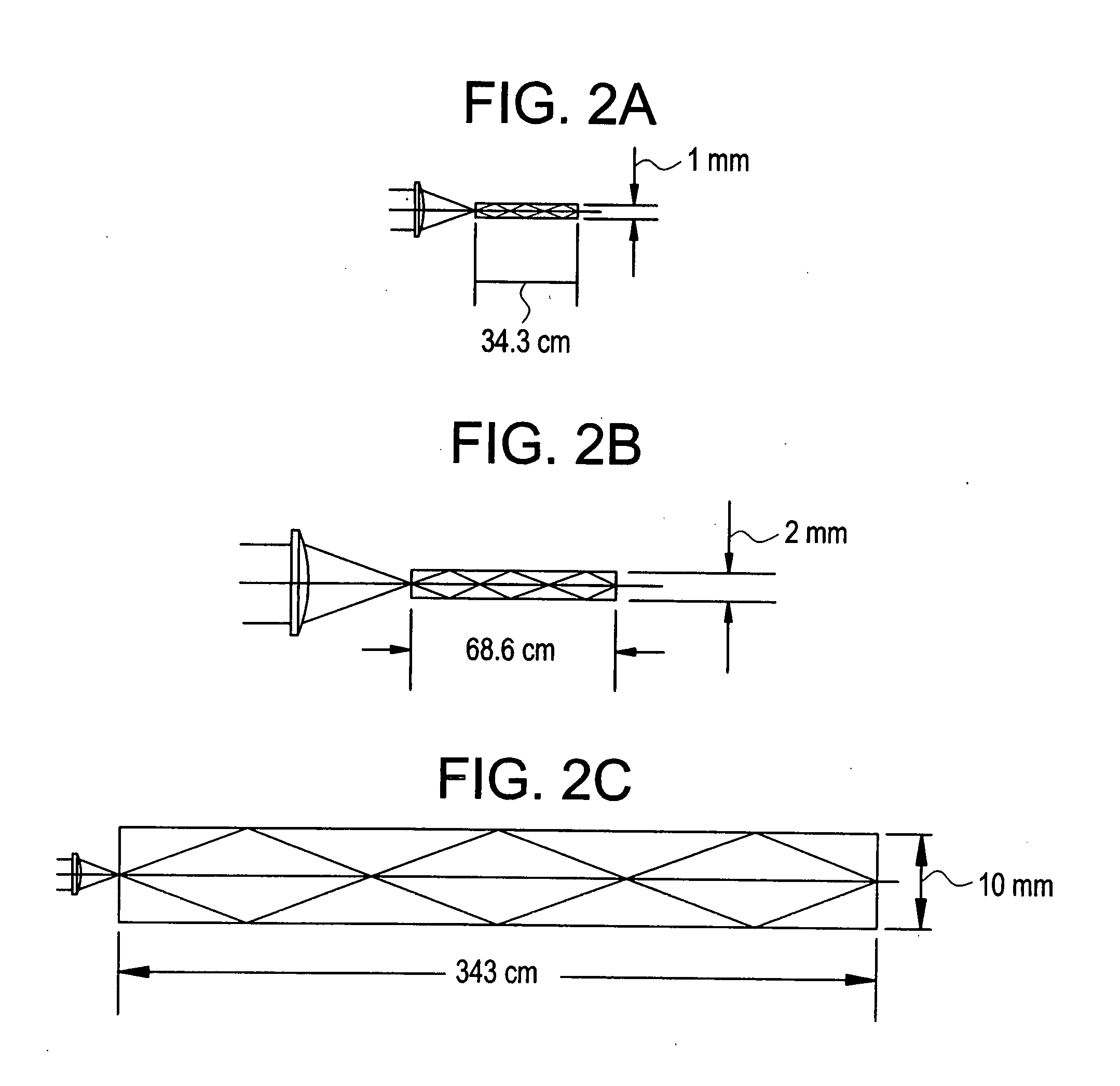

[0037] To the first order, the aspect ratio for such a rectangular illumination field may be determined in the following manner. The long dimension may equal the distance from the fly's-eye homogenizer focus to mask, multiplied by the result of dividing the wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com