Faux-stone architectural panel system

a technology of architectural panels and faux stones, applied in the field of faux stone architectural panel systems, can solve the problems of tedious process of arranging stones, requiring substantial skill, and achieving the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

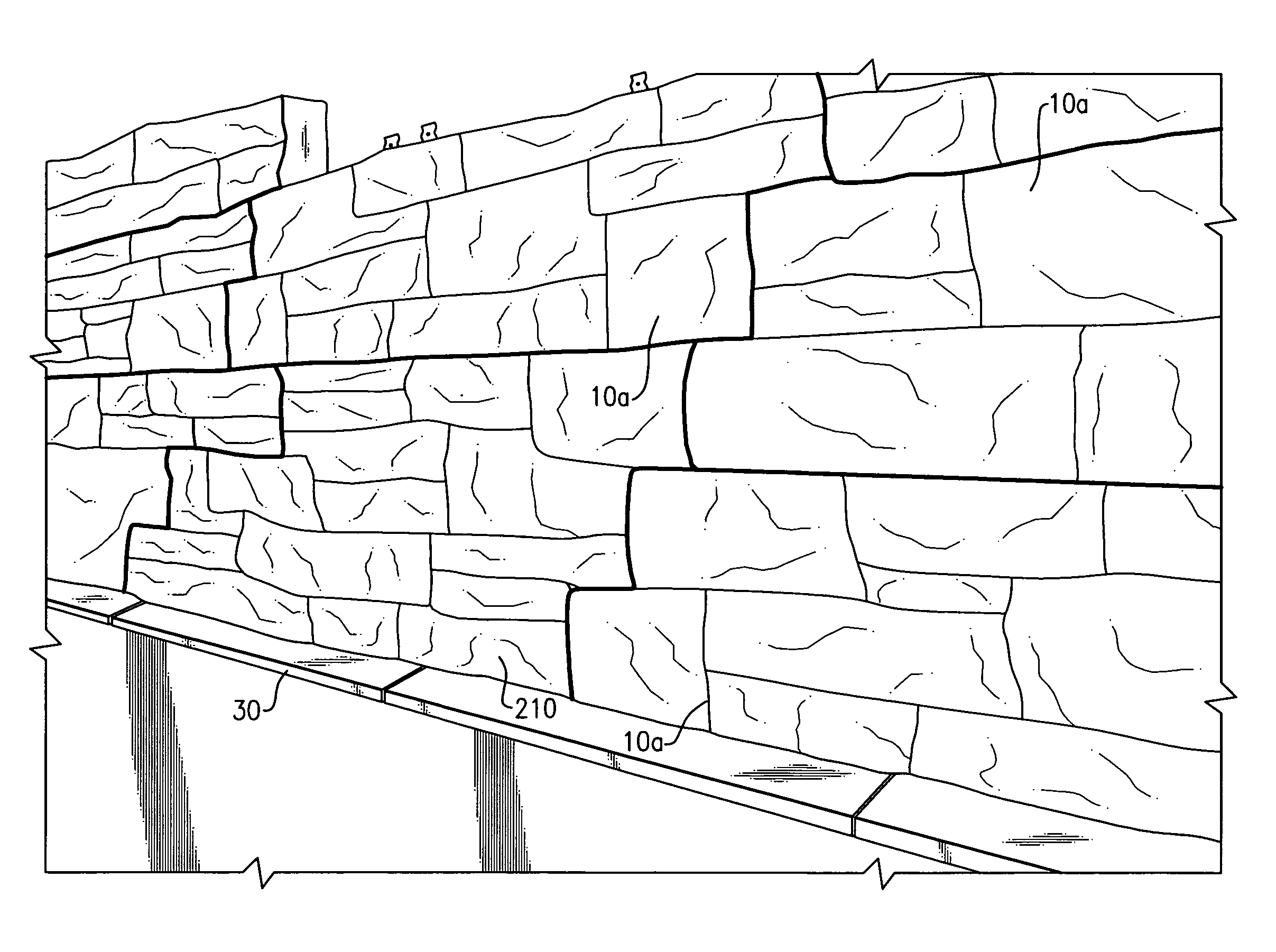

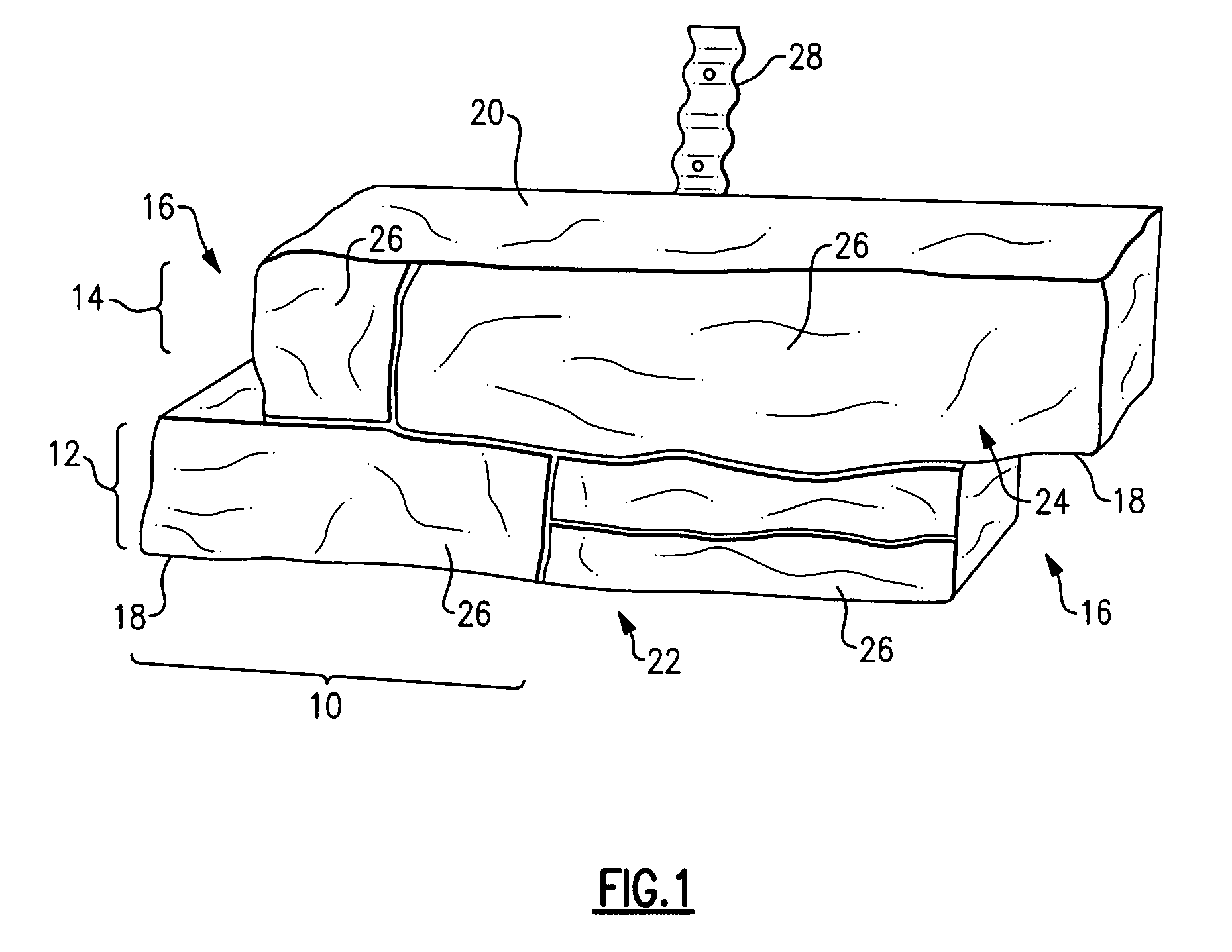

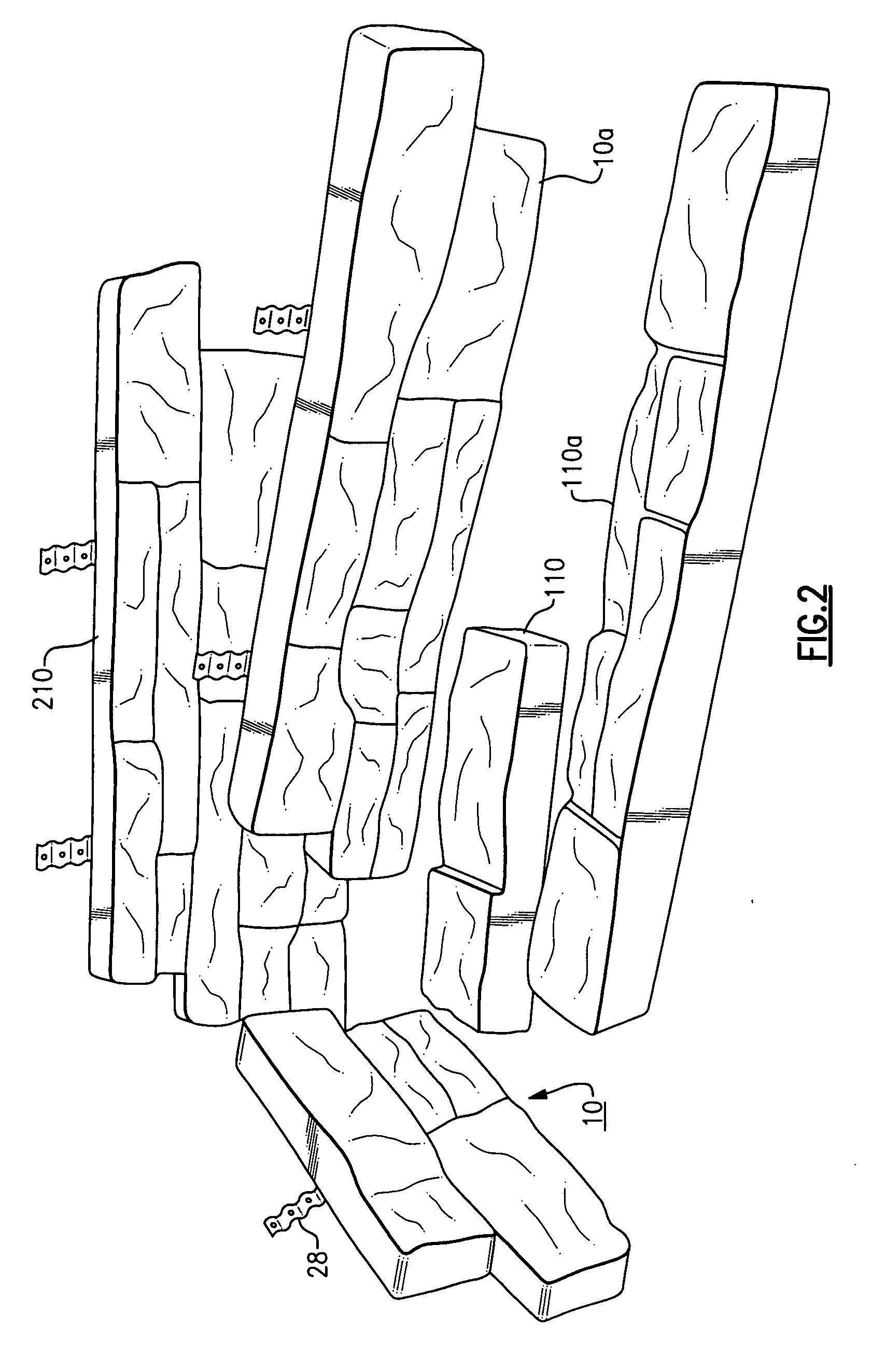

[0023] With reference to the Drawing, and initially to FIG. 1 thereof, a concrete faux-stone wall panel element 10 is shown here with a front face formed to simulate natural stones. The element 10 is molded of a concrete formed of a mixture of Portland cement and an aggregate made of light-weight material, preferably particles of vermiculite and zeolite, and possibly also pearlite. In some cases, particles of a plastic foam material, i.e., foamed styrene, can be used, as well as standard materials such as sand or other silicate-based material. The molding process will be described in more detail later.

[0024] Instead of Portland cement, a synthetic organic polymer may be used as a cement or binding agent, e.g., polyurethane, where appropriate for architectural purposes.

[0025] As shown here, the faux-stone panel is formed in two (or more) courses, which have the appearance of layers of stones situated vertically one atop the other. Here there is a first or lower course 12 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com