Pad, system and method for polishing, buffing, compounding and glazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Applicant now describes in detail embodiments of the claimed invention. The described embodiments are examples. This detailed description is not intended to limit the scope of the invention as claimed.

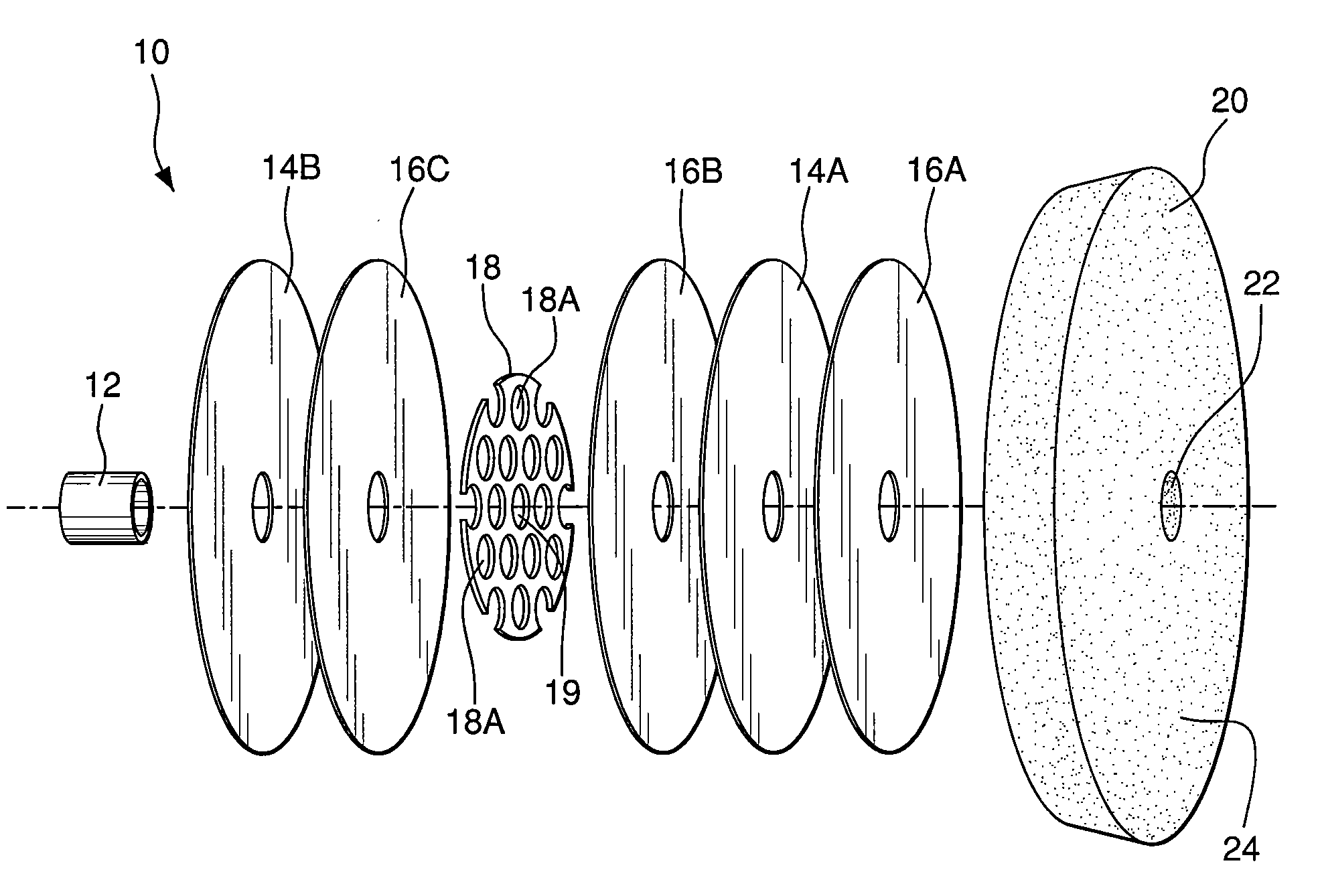

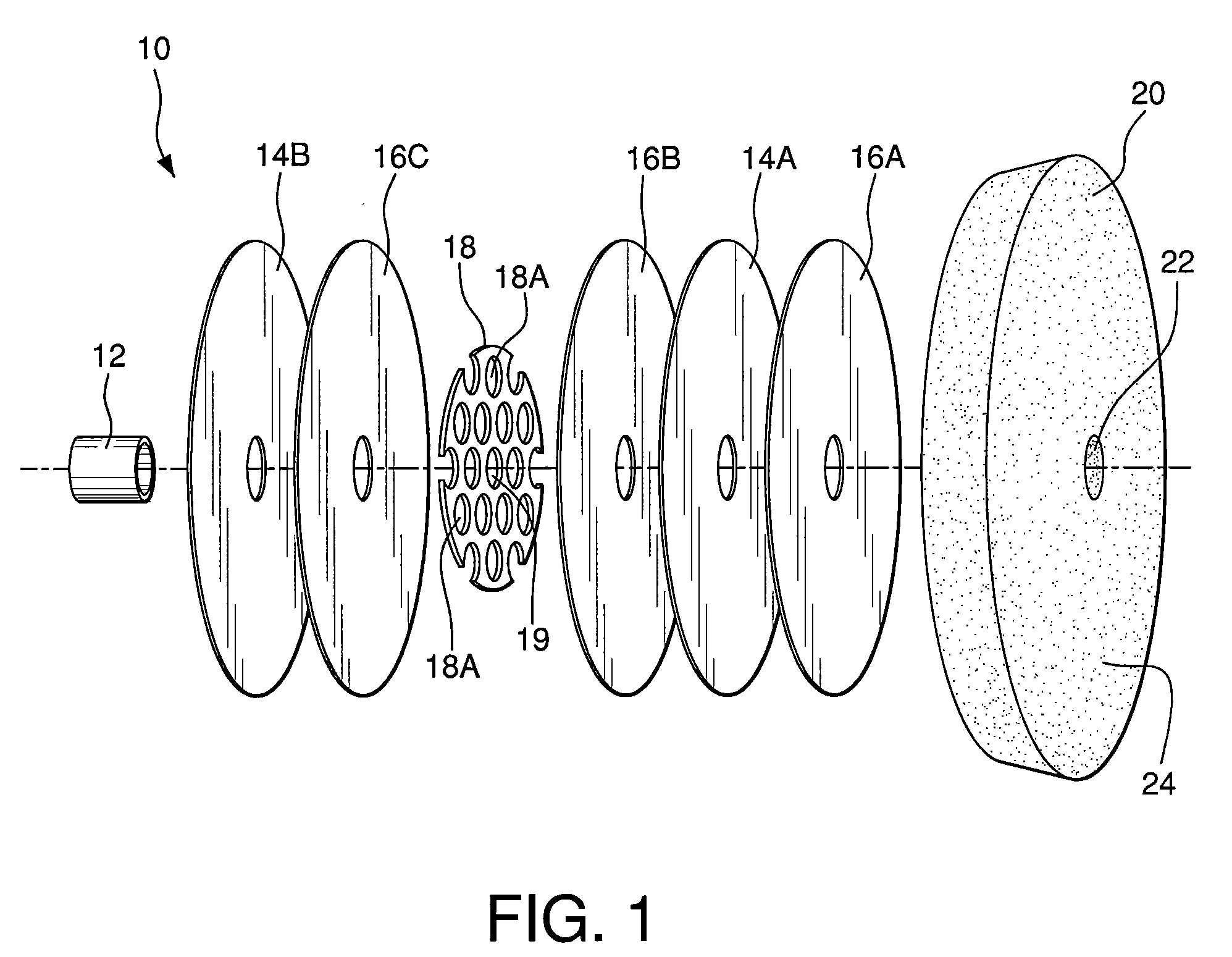

[0020]FIG. 1 shows an example of a system according to the claimed invention. In FIG. 1, surface-treatment pad 10 has: working pad 20 with central aperture 22 and front surface 24; insert 18 with threaded central aperture 19; first carrier layer 14A disposed between the rear surface of working pad 20 and said insert 18; first affixing layer 16A disposed between said first carrier layer 14A and said rear surface of said working pad 20; and second affixing layer 16B disposed between said insert 18 and said first carrier layer 14A so as to fix said insert 18 to said first carrier layer 14A. Surface-treatment pad 10 further has: second carrier layer 14B disposed upon the side of said insert 18 opposite said working pad 20; and third affixing layer 16C disposed between said second car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com