Fan frame structure

a technology of fan frame and fan body, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of weak strength of the fan body, not all the cooling systems are able to use the big-size fans, and the noise of the radiator device, so as to promote the heat dissipation effect, reduce noise and vibration, and strengthen the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

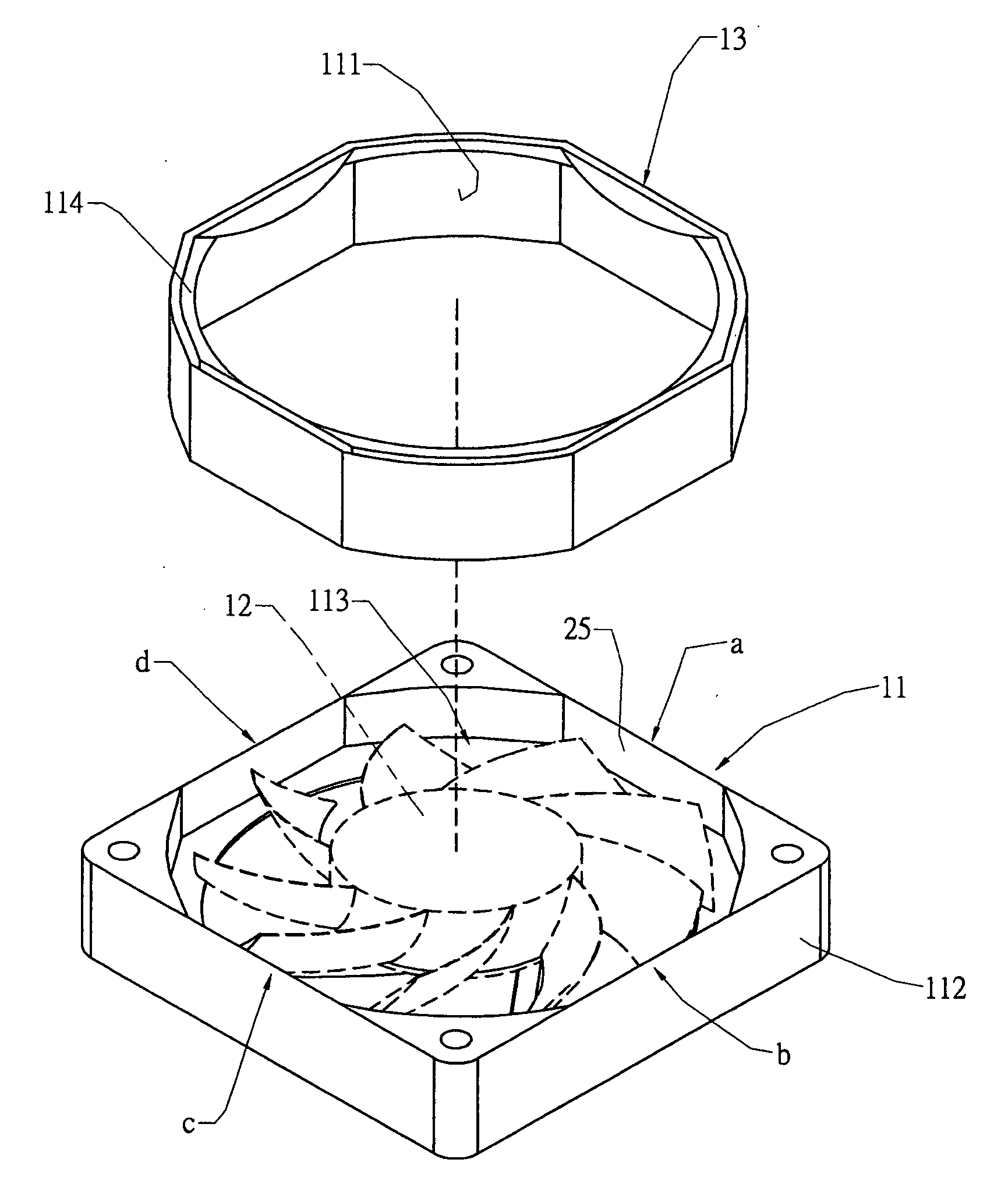

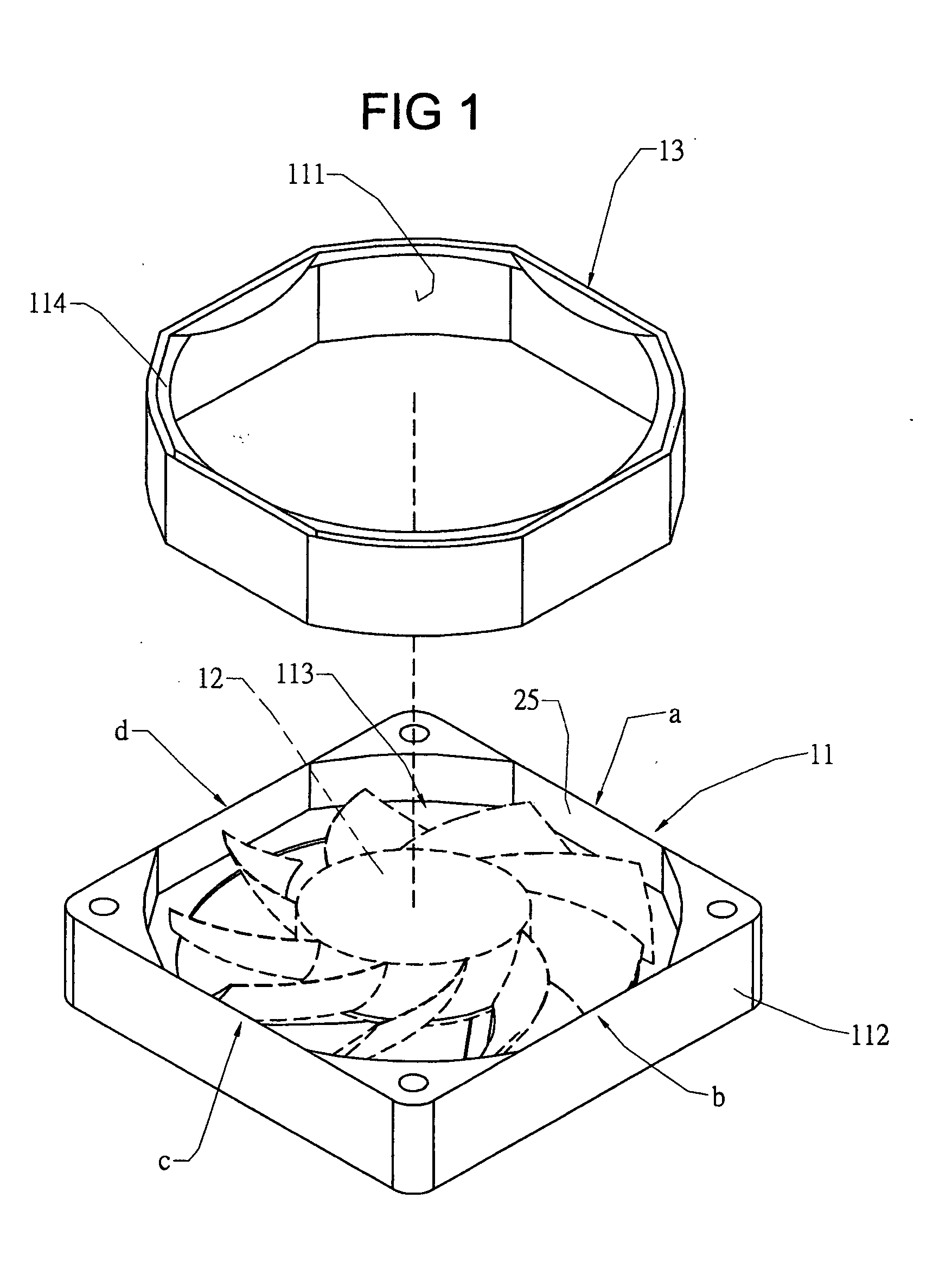

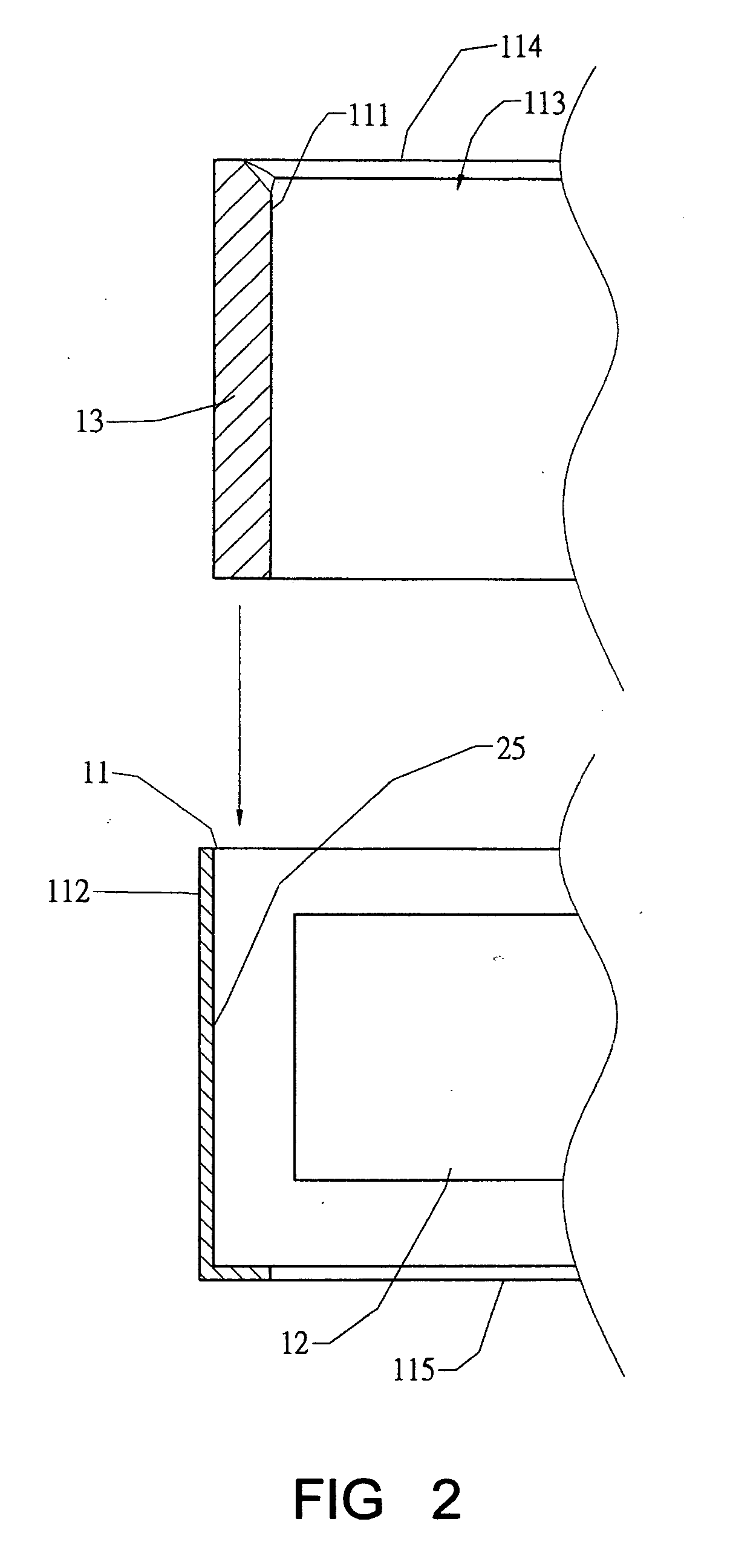

[0030] Referring to FIGS. 1 to 3, the first embodiment of a fan frame according to the present invention provides a frame member 11, which is made of plastics and has an inner frame side 111 and an outer frame side 112. The inner frame side 111 defines a space 113 for receiving a fan wheel 12. An inlet 114 and an outlet 115 are formed at two lateral sides of the space 113 respectively. The outer frame side 112 defines the size of the frame member 11. The frame member 11 has a receiving part 25 for accommodating a metal reinforcing member 13, which is shaped as strip ring, such that once the metal reinforcing member 13 is joined to the frame member 11 tightly, the metal reinforcing member 13 constitutes the inner frame side 111 to face the fan wheel 12 for strengthening the frame member 11.

[0031] The plastic frame member 11 provides a gross volume greater than the metal reinforcing member 13. Each of the four sides of the frame member 11 provides the shortest distance between the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com