Fan cover structure

a technology of fan cover and cover plate, which is applied in the direction of marine propulsion, liquid fuel engine, vessel construction, etc., can solve the problems of reducing the life span of electronic products, affecting the service life of electronic products, and the heat generated by running electronic components, etc., and achieves the effect of simple structure, easy assembly and convenient fixing on the casing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention has been described using exemplary preferred embodiments; anyone who is familiar with the arts can easily comprehend other advantages and effects of the present invention by reading the disclosed content in this claim. Moreover, the present invention can also be implemented or applied by using other embodiments, and anyone can modify and adjust the details in this claim on the basis of different considerations or applications, provided that he or she does not depart from the purpose and scope of the present invention. It should be noted that the figures in this claim are only simple examples and were not drawn according to actual size, which means the figures do not reflect the actual size of the relevant structures.

[0021] The following embodiments are only used to elucidate the present invention, and are not to be used to limit the scope of it.

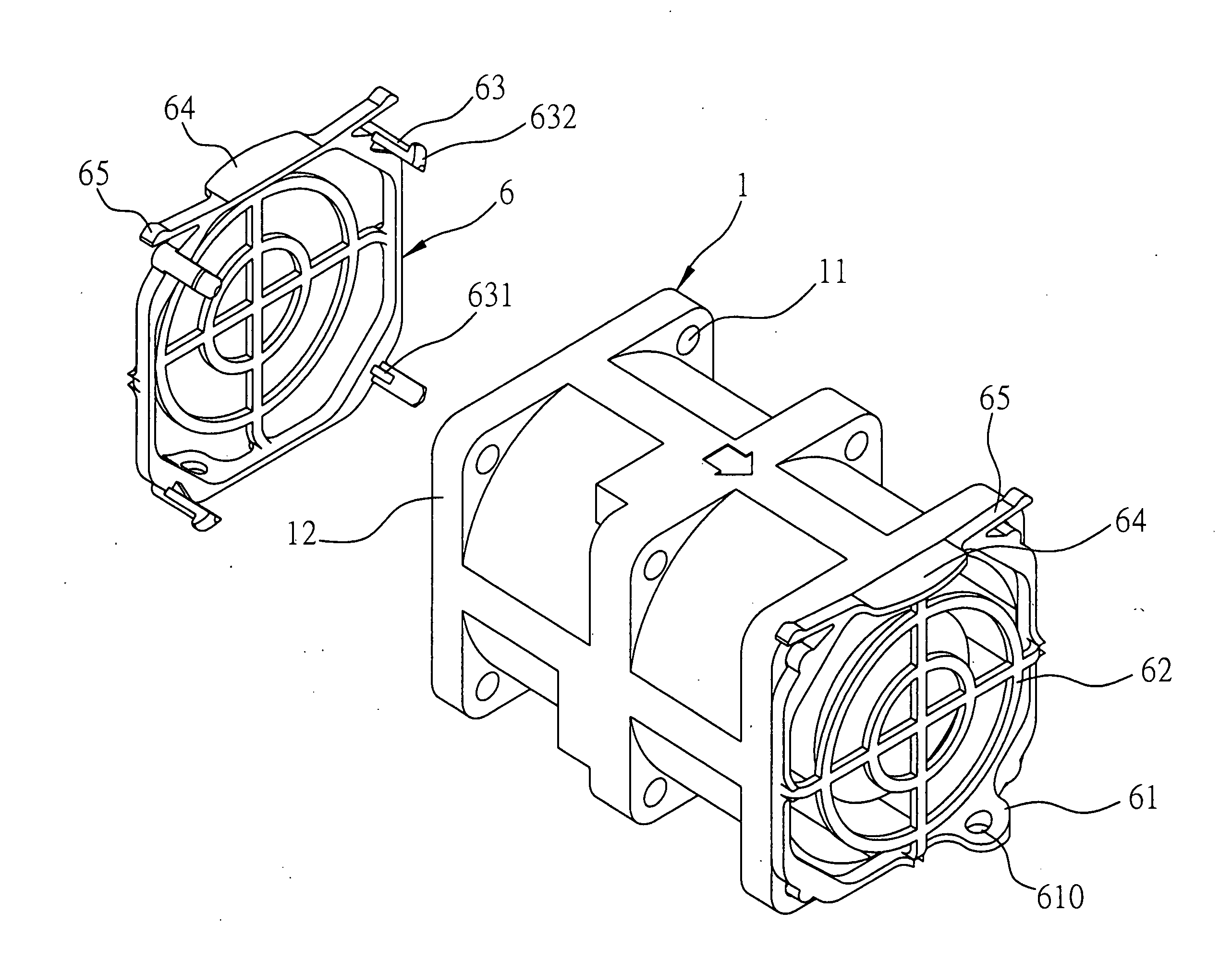

[0022] Referring to FIG. 3, which is a schematic view showing the fan cover structure of the present invention to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com