Polishing method and polishing apparatus

a polishing apparatus and polishing method technology, applied in the direction of manufacturing tools, cleaning using liquids, abrasive surface conditioning devices, etc., can solve the problems of difficult to completely remove foreign matter adhering to the polishing member, uneven rubbing of the polishing member with a brush, and difficult to remove foreign matter from the polishing member, etc., to achieve the effect of preventing foreign matter adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0107]Preferred embodiments of the present invention will now be described with reference to the drawings.

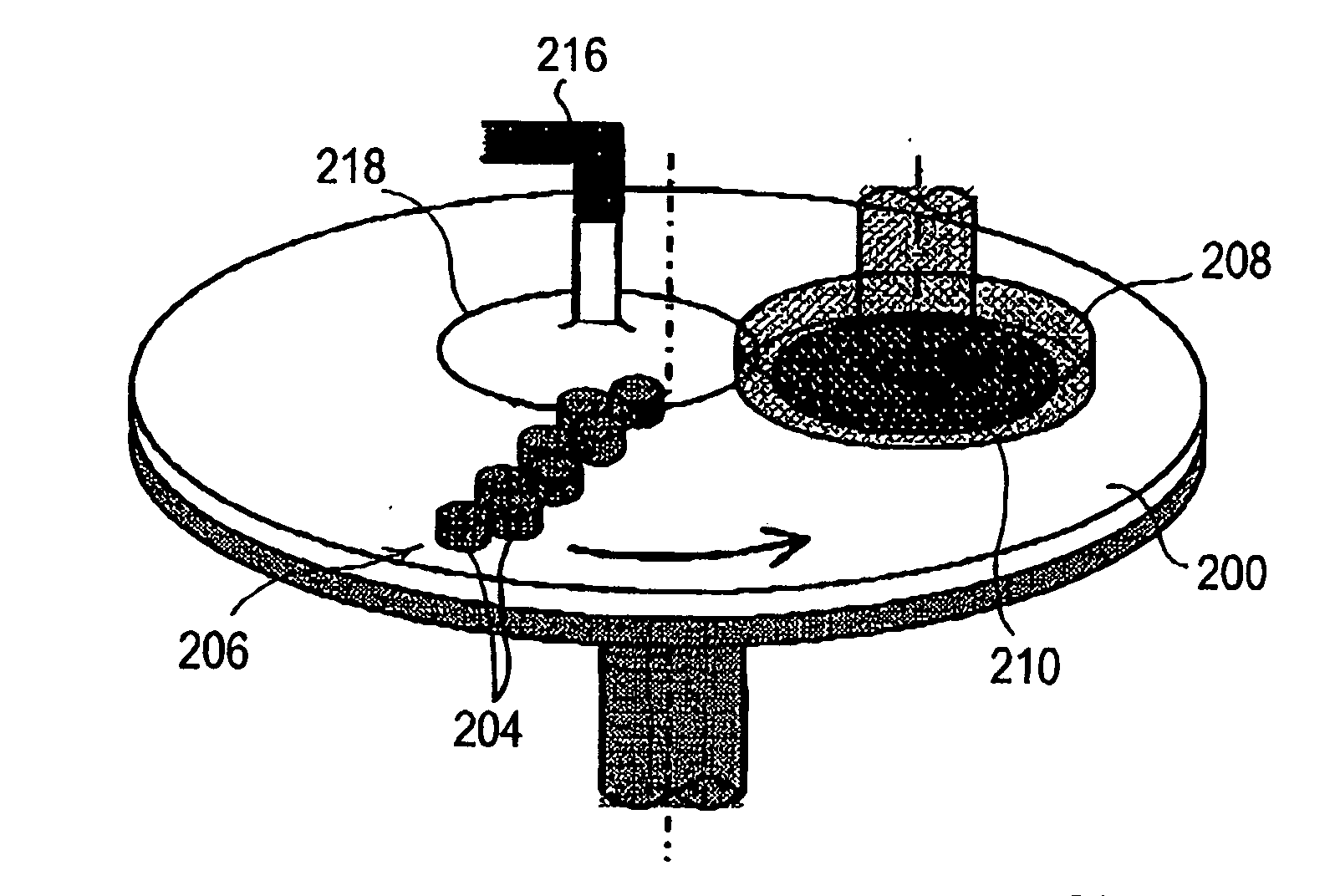

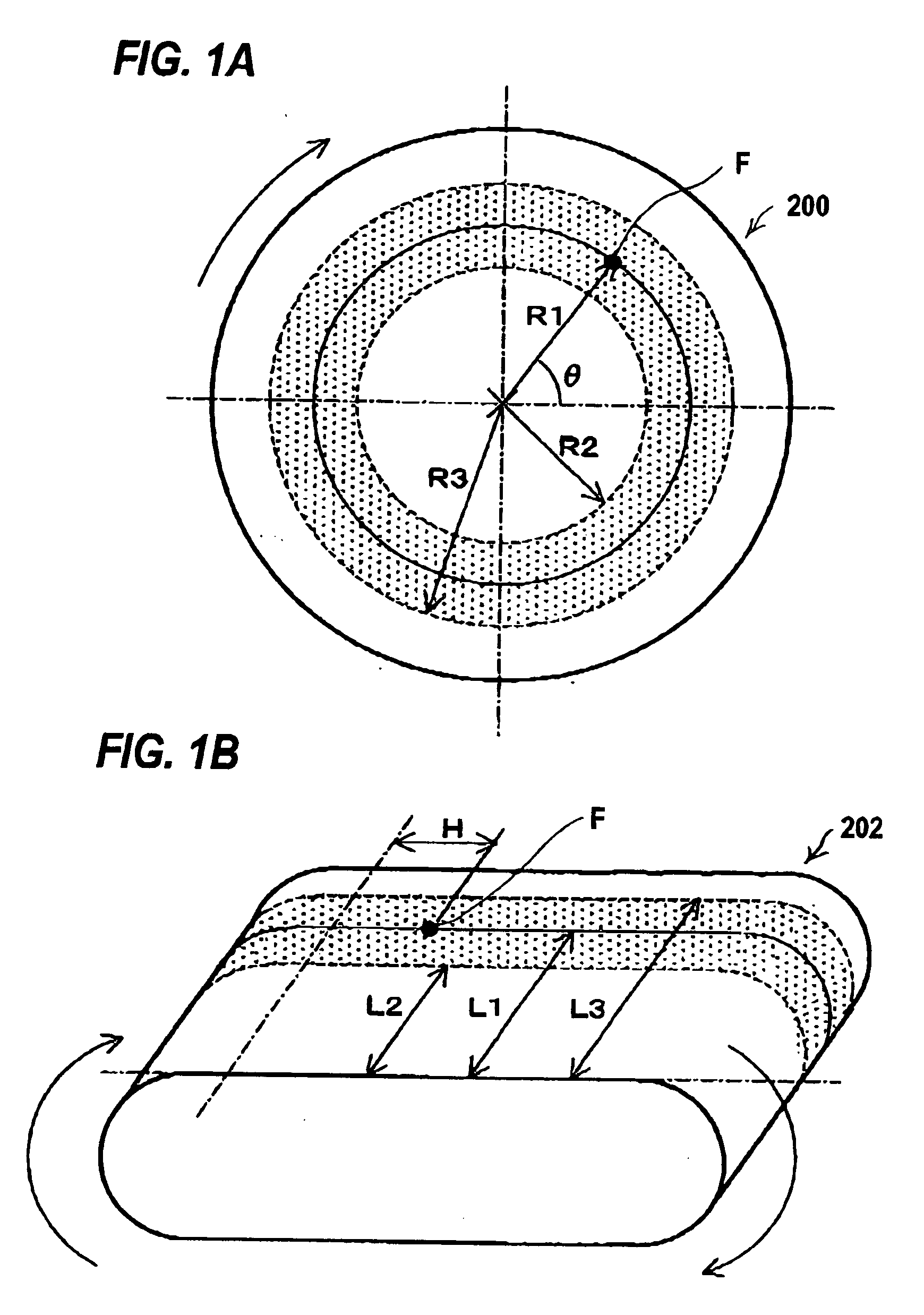

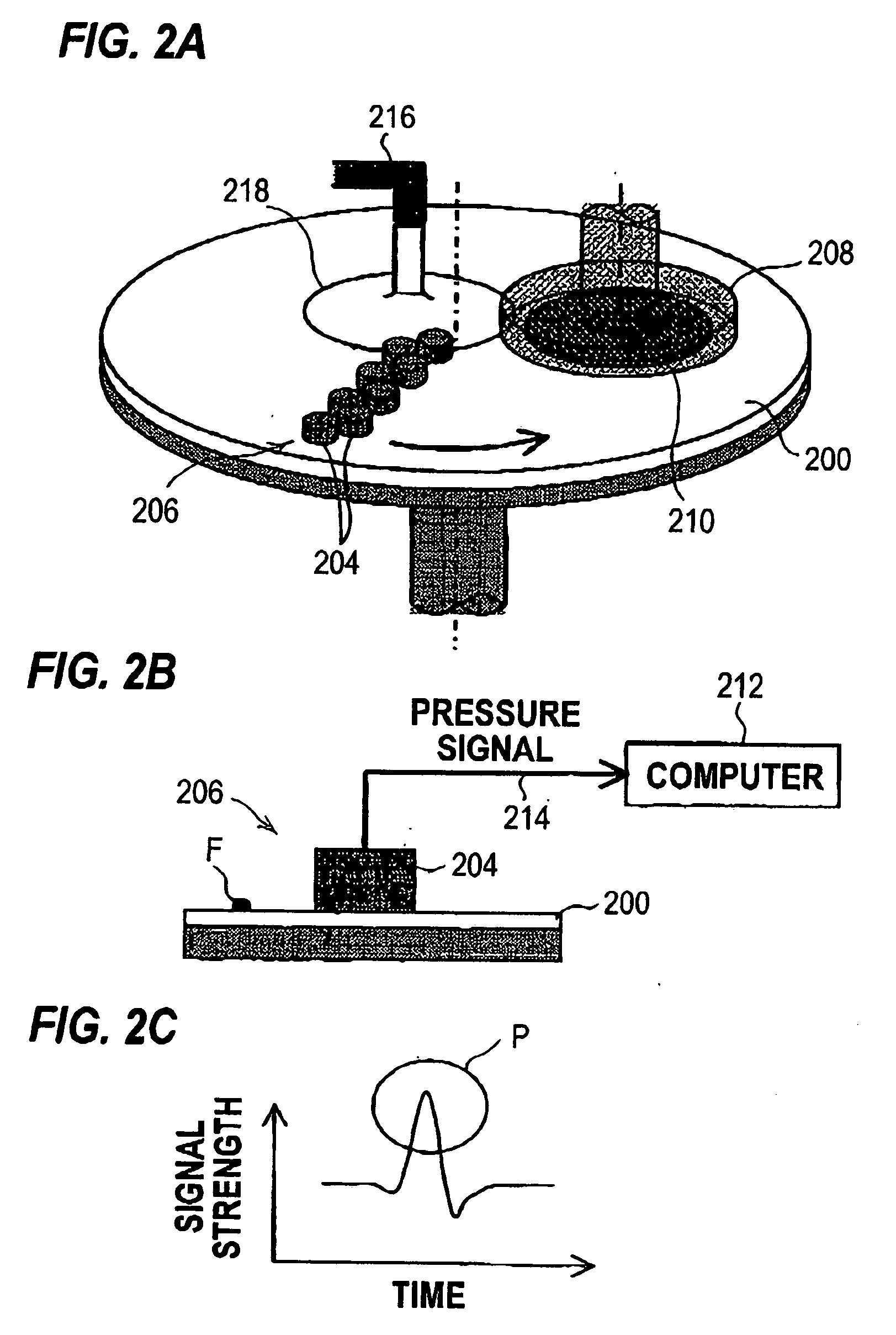

[0108]At the outset, the terms “foreign matter adhesion position” and “foreign matter adhesion area”, in a surface of a polishing member, such as a polishing pad, to which foreign matter is adhering, will be described with reference to FIGS. 1A and 1B. In general, a polishing member, such as a polishing pad, is not in a fixed or stationary state during polishing, but is making a rotational movement in the case of a rotary polishing member 200, as shown in FIG. 1A, or a linear movement in the case of an endless belt-type polishing member 202, as shown in FIG. 1B.

[0109]The term “foreign matter adhesion position” refers to the exact position of adherent foreign matter in a surface of a polishing member. Thus, as shown in FIG. 1A, when a fixed reference coordinate system (polar coordinate system is illustrated in the Figure) is taken on the surface of the rotary polishing member 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius R1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com