Fired heater and flue gas tunnel therefor

a flue gas tunnel and heater technology, applied in the field of fired heaters and flue gas tunnels therefor, can solve the problems of significant shortcomings, high construction cost, time-consuming and labor-intensive, etc., and achieve the effect of reducing the number of slintels or tile covers, and reducing the cost of installation, maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

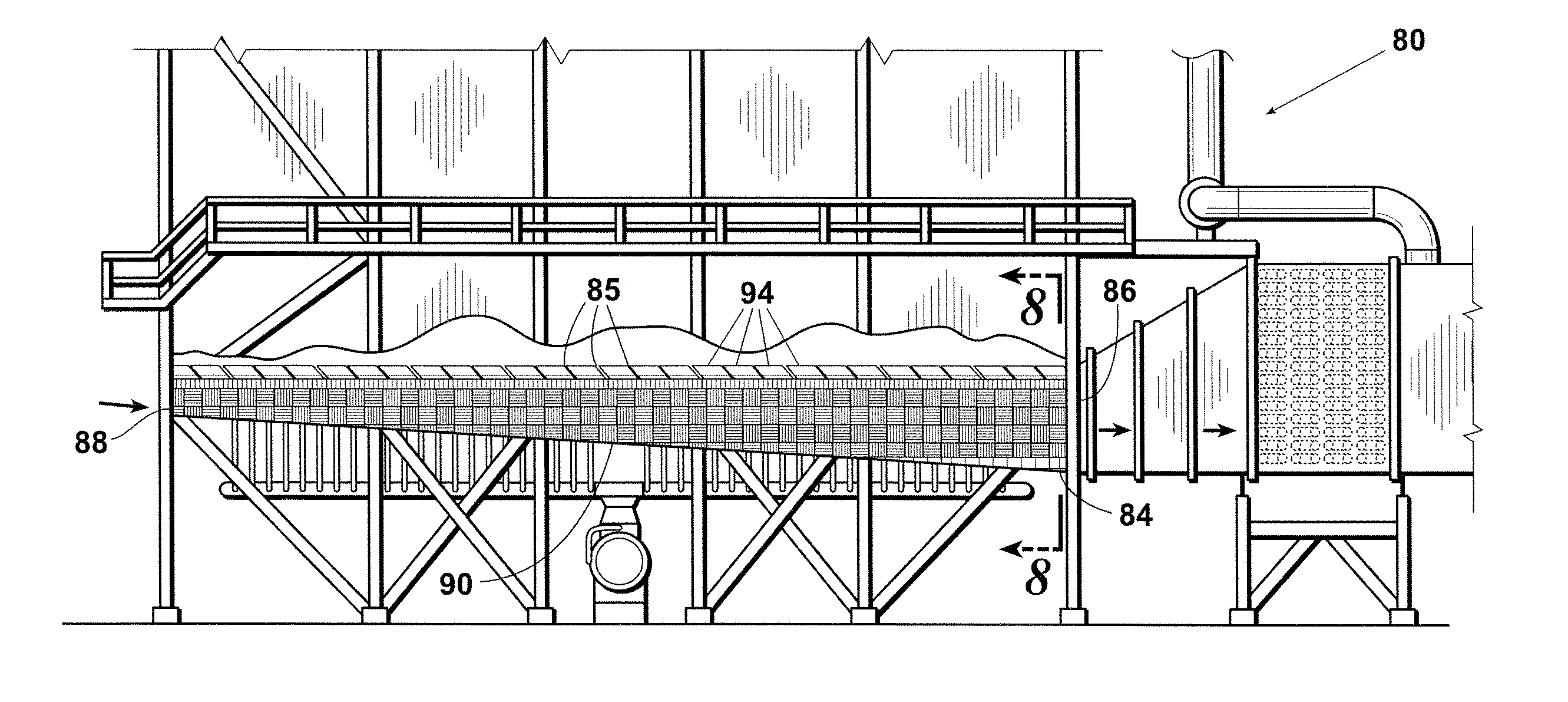

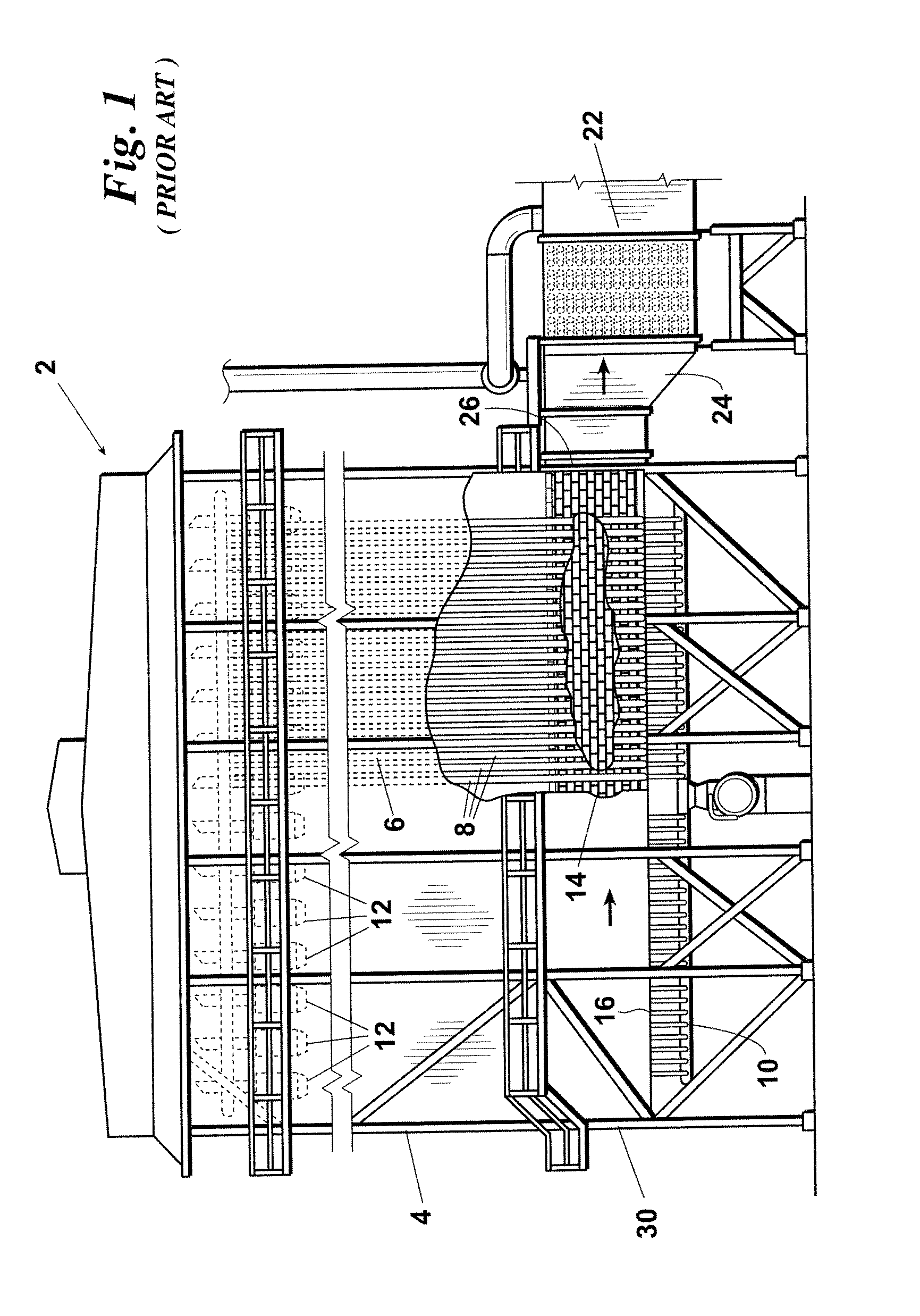

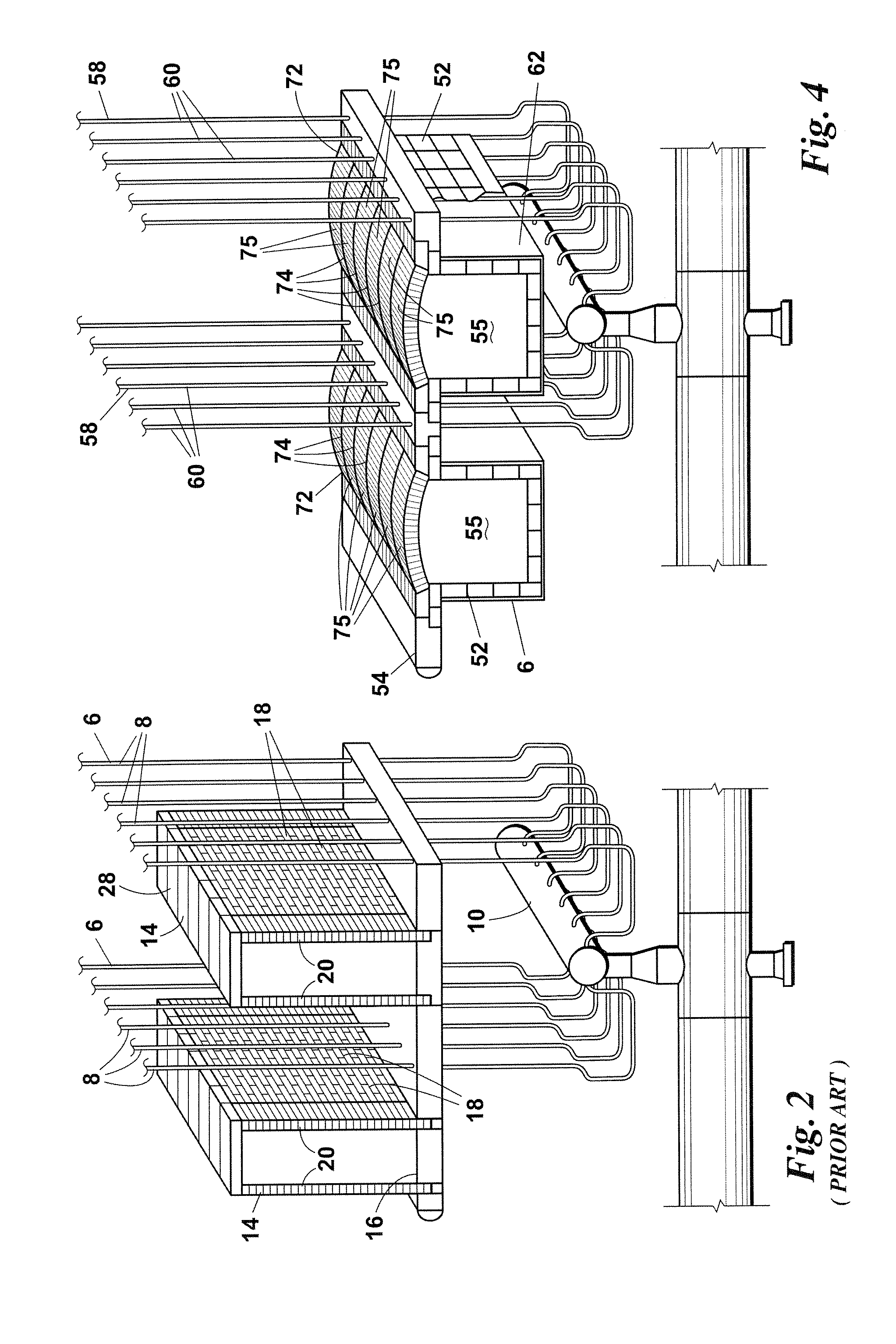

[0030] Simulations were run using computer models of (a) a top-fired reformer heater utilizing the prior art flue gas tunnel system depicted in FIGS. 1 and 2 and (b) a top-fired reformer heater employing the inventive flue gas tunnel system illustrated in FIGS. 7-9. The simulations employed: a standard high Reynolds number turbulence model; a discrete ordinates (S4 for ordinate set) method for computing thermal radiation heat transfer; and the weighted sum of gray gases method to compute the gas absorption coefficient assuming natural gas combustion at 10% excess air. Meshes were prepared using the advanced meshing module of Prostar 3.26. The simulations each employed between 1.1 and 1.8 million cells and each required over 60 CPU-hours of processing time.

[0031] The models simulate flue gas flow, convection heat transfer from the flue gas to the heater coils, and radiative heat transfer to the coils from the flue gas and refractory surfaces. The flue gas flow is specified as six fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com