Chemically Stiffened Fibers In Sheet Form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

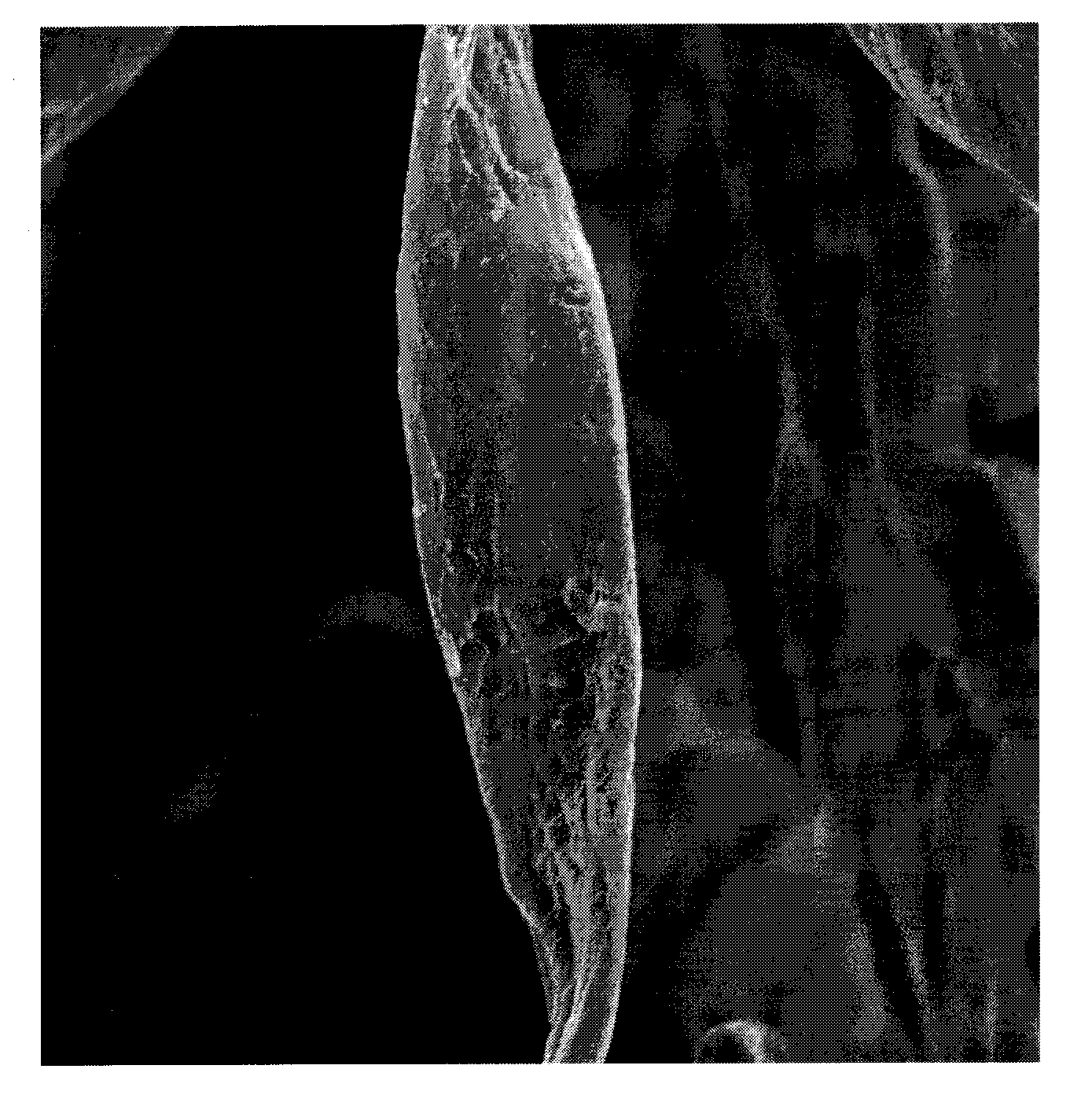

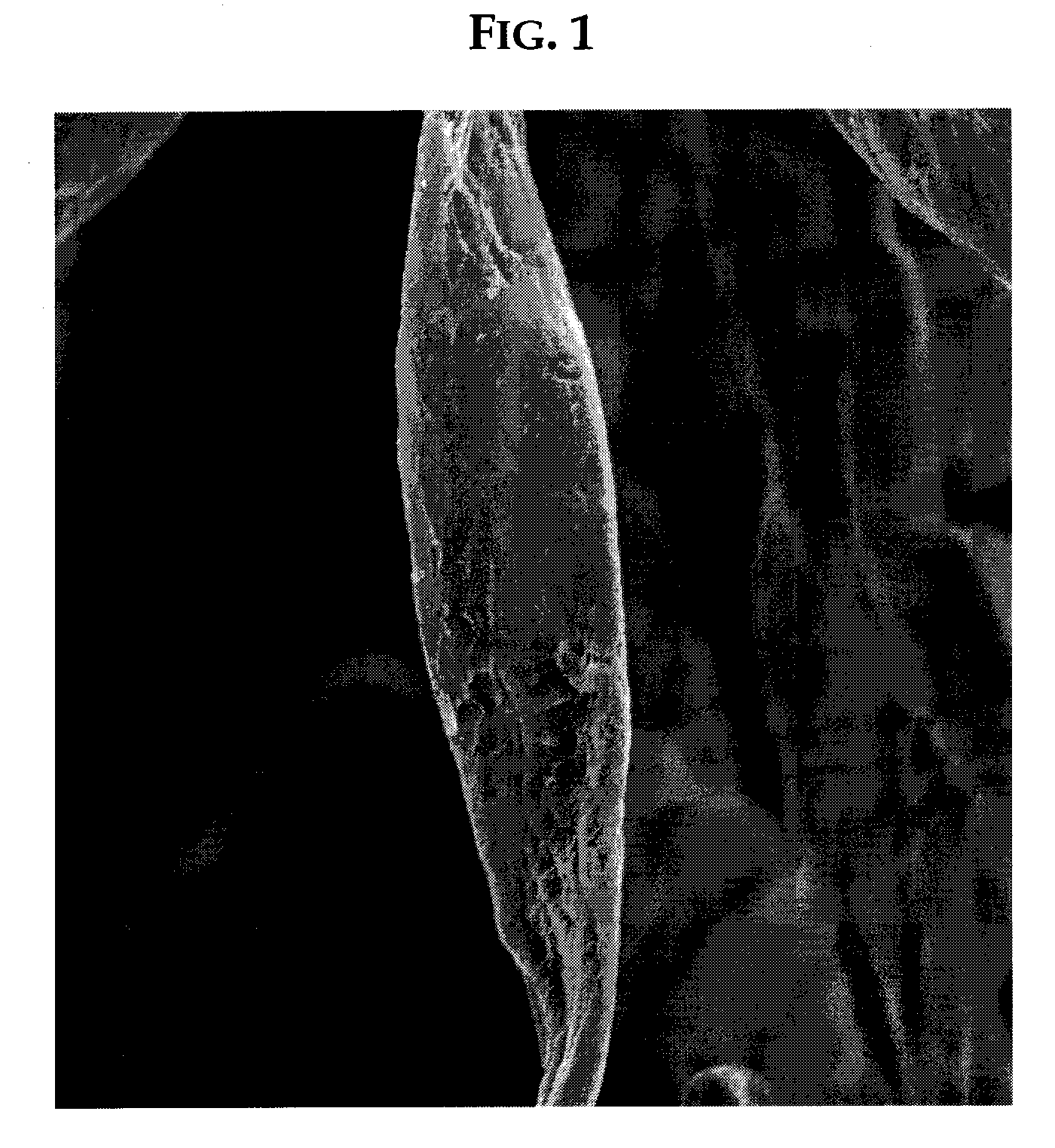

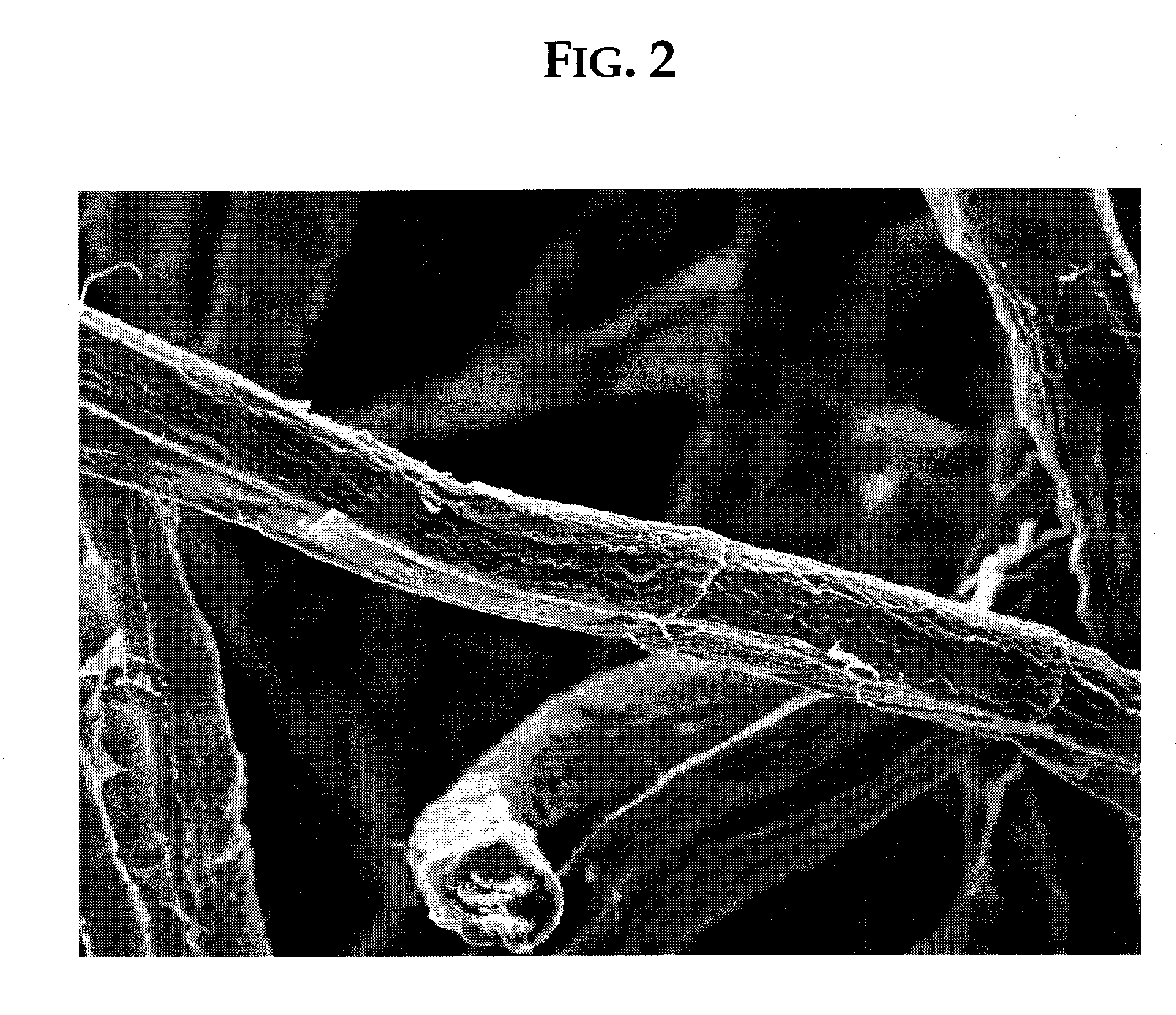

Image

Examples

example 1

[0101]This example illustrates a representative method for making stiffened fibers in sheet form.

[0102]In this method a treatment composition solution containing citric acid (3.2 weight %), polymaleic acid (0.8 weight %), and a catalyst sodium hypophosphite (0.8 weight %) was prepared. The pH of the solution was adjusted to about 3.0 with an aqueous solution of NaOH (50 weight %).

[0103]The treatment composition solution then used to treat hand sheets of fluff pulp obtained from a jumbo roll of Rayfloc®-J-LD (conventional wood fluff pulp, commercially available from Rayonier, Inc., Jesup, Ga.). The hand sheets each had dimensions of 11 inches by 11 inches, a basis weight of about 680 gsm (g / m2), and density of 0.42 g / cc. Each hand sheet was dipped in the treatment composition solution and pressed to achieve the desired level of treatment composition solution (100% wet pick-up). The treated sheets were then dried and cured at about 186° C. in an air-driven laboratory oven for about 10...

example 2

[0105]This example illustrates an alternative method for making stiffened fibers in sheet form.

[0106]A 12 inch by 12 inch hand sheet of stiffened fibers with a basis weight of about 650 gsm was made in the following manner: Rayfloc®-J-LDE (65.0 g, moisture content about 7%) was dispersed in water then added to a handsheet chamber. An aqueous solution of citric acid, PMA, and sodium hypophosphite was added to the fiber suspension in the hand sheet chamber. More water was then added so that the final volume of the mixture was 10.0 L, and the mixture contained 3.2 wt % citric acid, 0.8 wt % PMA, and 0.7 wt % sodium hypophosphite. The pH of the solution was adjusted to about 3.0 by adding sodium hydroxide solution (50%). The suspended fibers in the handsheet mold were then gently agitated with a standard perforated mixing plate that was inserted into the slurry and moved up and down about 12 times, then removed. The water was then drained through the forming screen of the handsheet form...

example 3

[0109]This example illustrates a method for making acidic stiffened fiber.

[0110]In this example, the procedure described in Example 1 was followed, except that in this experiment after curing the sheet of stiffened fiber was treated with an aqueous solution of citric acid. Three sample sheets were produced, one having 1.0 weight % citric acid, a second having 1.5 weight % citric acid, and a third having 2.0 weight % citric acid, based on the to total weight of the stiffened fiber sheet.

[0111]The pH of the acidic stiffened fiber samples was measured using the following method. 10.0 g of stiffened cellulosic fiber was saturated with distilled water (50.0 g). The produced mixture was left for about 10.0 minutes, after which about 10.0 grams of liquid was squeezed out of the fiber. The pH of the squeezed liquid was measured and used as the pH of the fiber. The results are summarized in Table 2, below.

TABLE 2pH of acidic stiffened fibers prepared asshown in Example 3Acquisition fiberCitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com