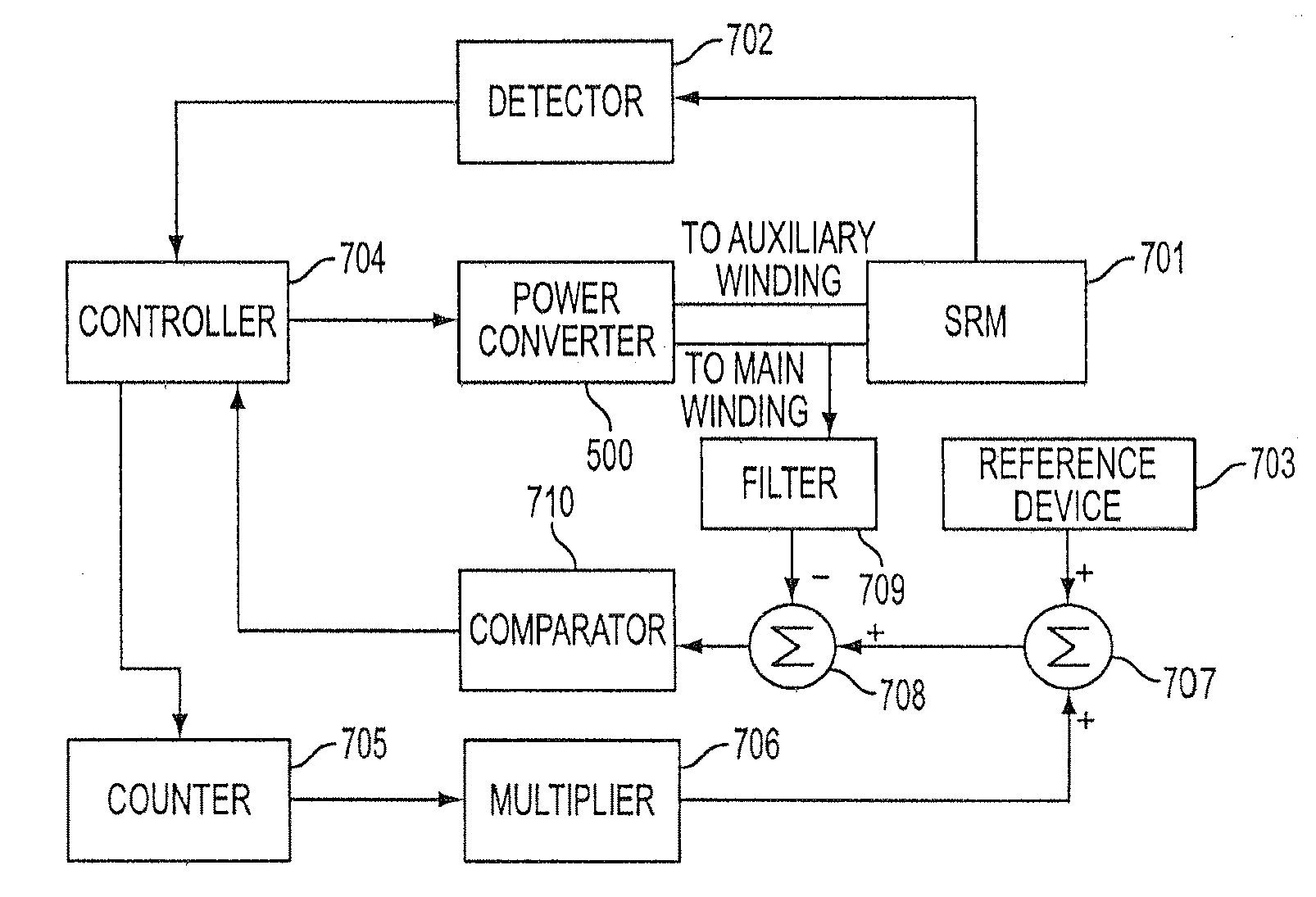

Method, apparatus, and system for drive control, power conversion, and start-up control in an srm or pmbdcm drive system

a technology of a power converter and a drive system, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, and shape/form/construction of magnetic circuits, etc. it can solve the problems of reducing the available dc source voltage by half, using eight power devices, and reducing the overall cost of a brushless power converter. , the effect of reducing the size of the power converter's packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

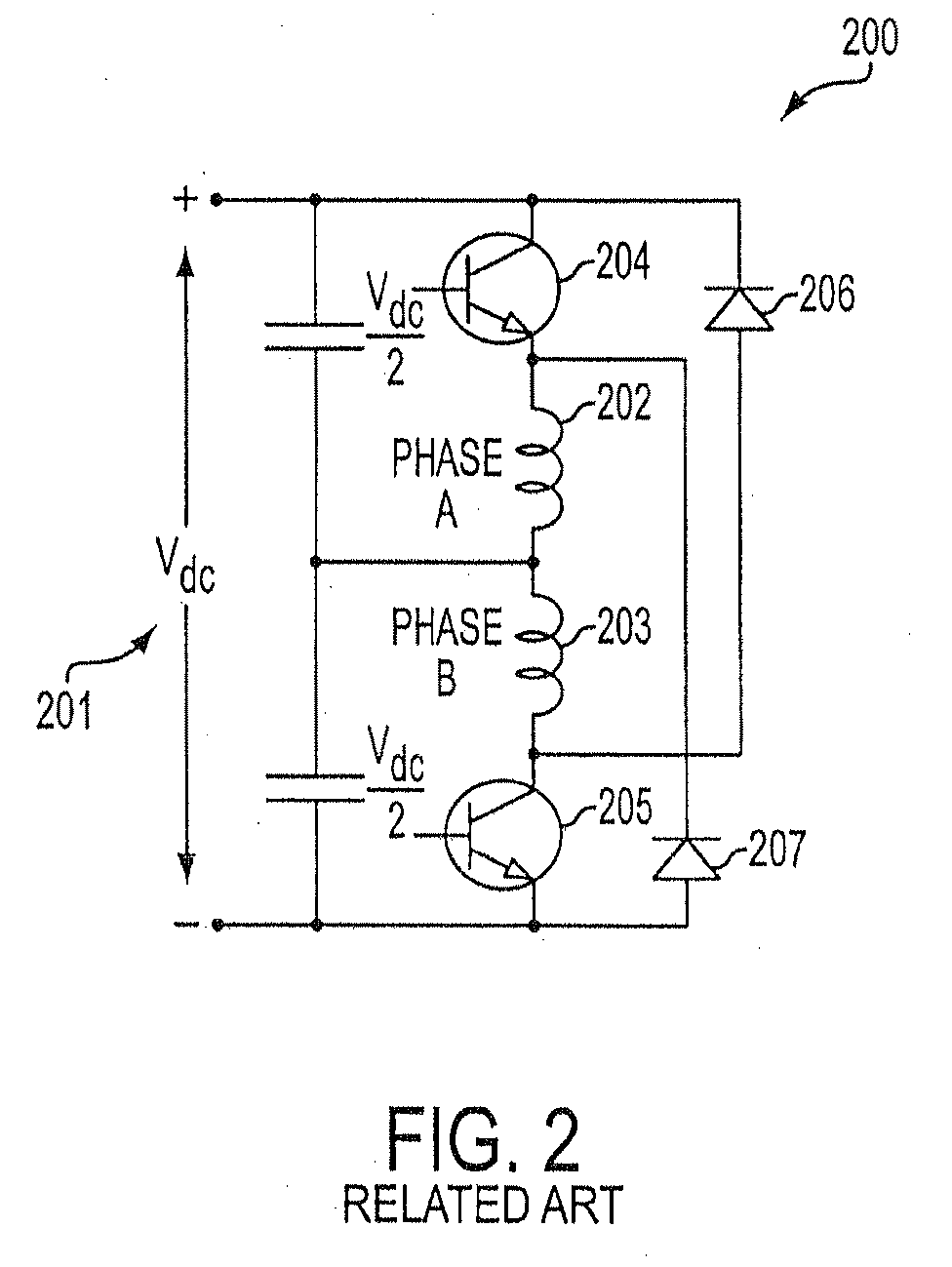

[0050]FIG. 5(a) illustrates a single-switch power controller in the form of converter 500 for driving a two-phase switched reluctance machine (SRM) according to the present invention. One winding of the SRM is alternatively referred to as a main or phase A winding 508, while the other winding is referred to as an auxiliary or phase B winding 505. Although the phase windings 505, 508 of the SRM may be spatially separated from the power converter 500 and may also be considered to form a part of the motor rather than part of the power converter, these windings 505, 508 are illustrated in the power converter circuit for the purpose of simplifying the description of their cooperative functionality with the power converter 500. For this reason, the windings 505, 508 will be illustrated within each embodiment of the power converter 500 described hereinafter.

[0051] When power converter 500 is activated by the application of an ac source voltage 501, a dc source 510 comes into effect throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com