Compositions and Methods for Producing Fermentation Products and Residuals

a technology of residuals and fermentation products, applied in the field of ethanol fuel industry, can solve the problems of low initial investment, two to four times less capital cost per gallon, and the current ethanol industry could be significantly affected, so as to increase the production of nutritional components, maximize the profit from fermentation reaction, and enhance nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Construction of Expression Vectors:

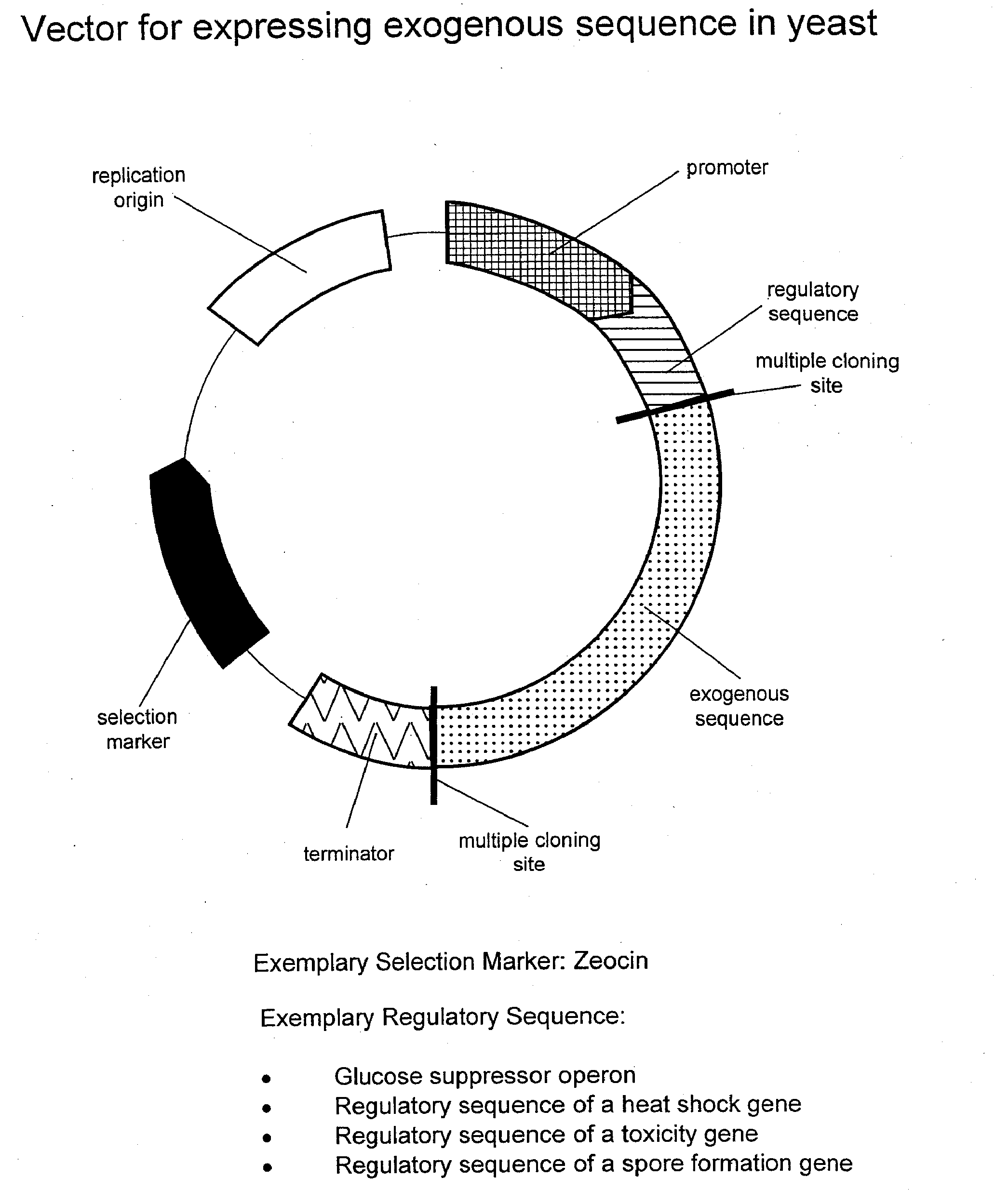

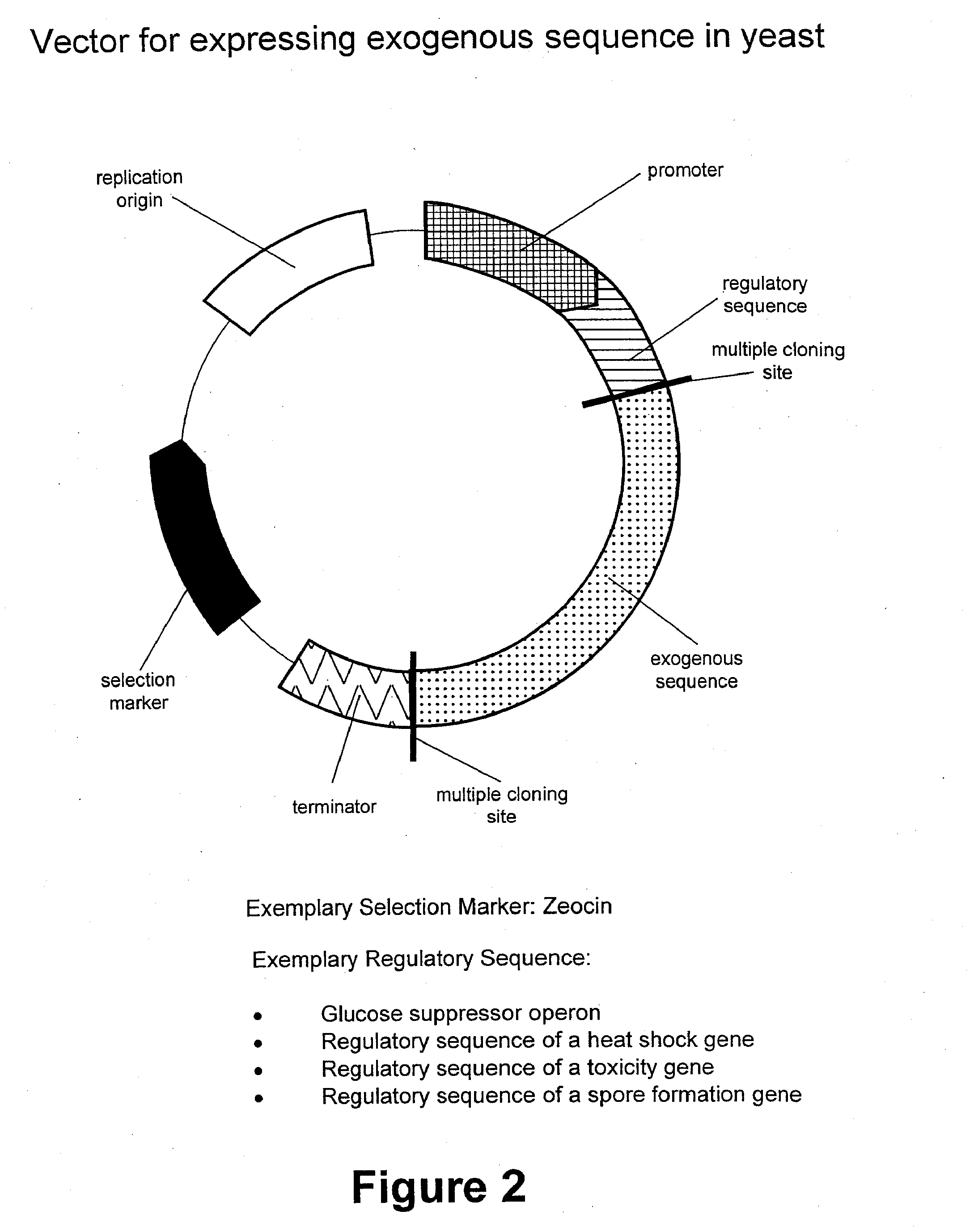

[0152] An expression vector suitable for producing an exogenous sequence in a microorganism such as yeast cell is constructed according to standard recombinant techniques. The vector comprises a replication operon capable of replication in the yeast cell, an exogenous sequence of interest that is operably linked to a regulatory sequence controlling the expression. The vector is made optionally replicable in prokaryotes (i.e., a shuttle vector) such as bacteria to facilitate cloning. In addition, the vector comprises a regulatory sequence such as a glucose suppressor operon that normally suppresses the expression of the exogenous sequences and until when the glucose content in the medium is low or about to be depleted.

[0153] The expression vector is typically constructed to contain a selectable marker (for example, a gene encoding a protein necessary for the survival or growth of a host cell transformed with the vector), although such a marker ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fermentation time | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com