Centrifugal Fluid Filtration Devices, Systems and Methods

a centrifugal fluid and filtration device technology, applied in centrifuges, separation processes, filtration separation, etc., can solve the problems of increasing energy dilemma, salt water, and requiring an expensive and energy-intensive desalination process, so as to reduce the cost, less space, and less time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

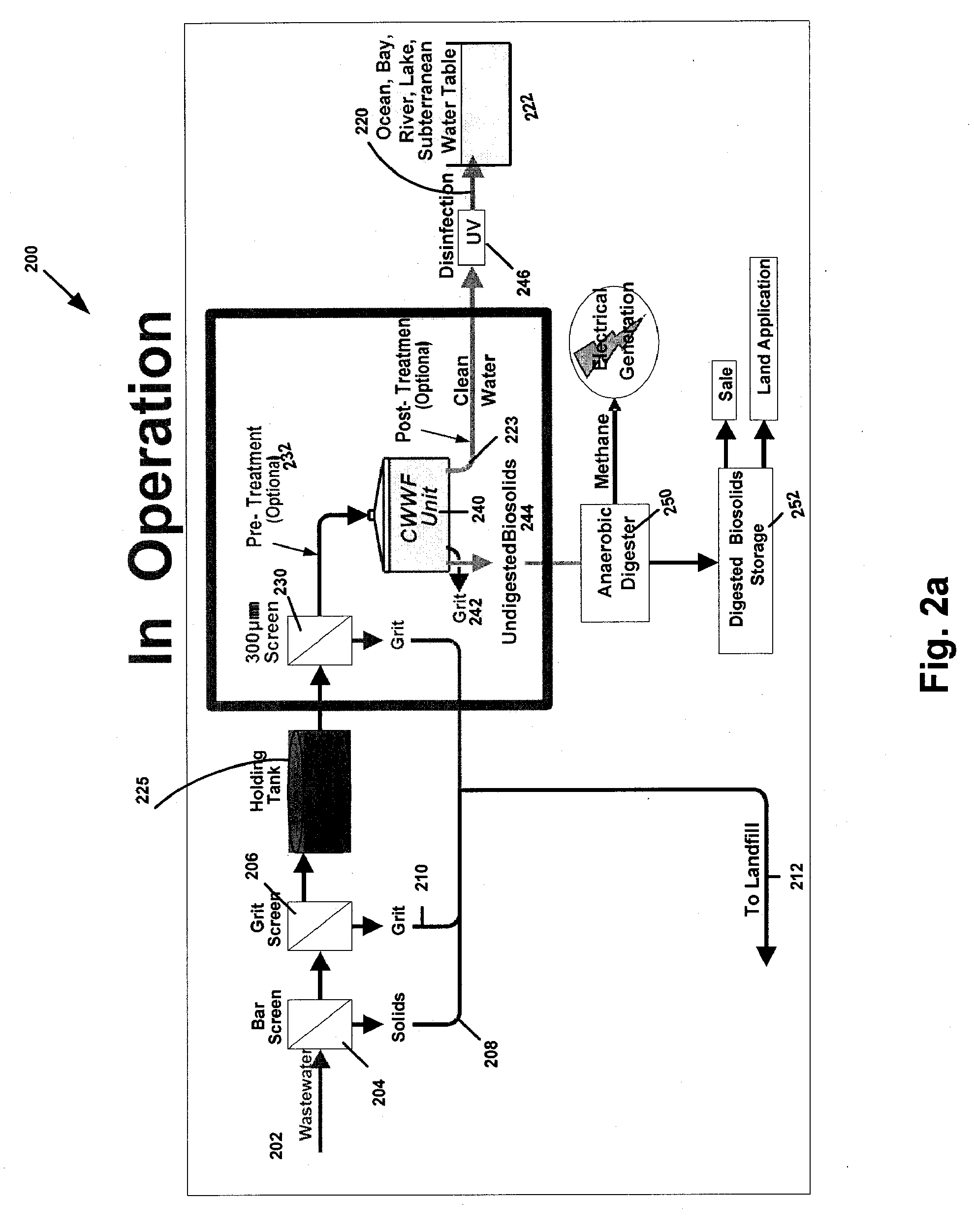

[0039]For purposes of illustration of the concepts of the invention, the various features are discussed with respect to wastewater treatment. However, those skilled in the art will appreciate that the teachings can be applied to other industries such as pharmaceutical and food processing. Commercial applications for this invention are numerous and include, but are not limited to: drinking water and wastewater treatment for municipalities; non-community wastewater systems and housing developments; and wastewater treatment for commercial business developments, condominiums, malls, hotels / motels, office buildings, hospitals, resorts, and government and military installations. Additional applications may include, but are not limited to, isolation, separation, purification, removal, recovery, and / or concentration of biological components in the pharmaceutical and biotechnology industries. The device may also be used for water clean-up in power plants; and water and wastewater clean-up in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| antifouling effect | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com