Audio equipment storage device

a technology for audio equipment and storage devices, applied in the direction of movable shelf cabinets, dismountable cabinets, folding cabinets, etc., can solve the problems of reducing the quality of listening or viewing experience for individuals, causing primary sources of vibration in audio equipment, and affecting the listening or viewing experience of individuals, so as to reduce, ameliorate, or eliminate the deleterious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

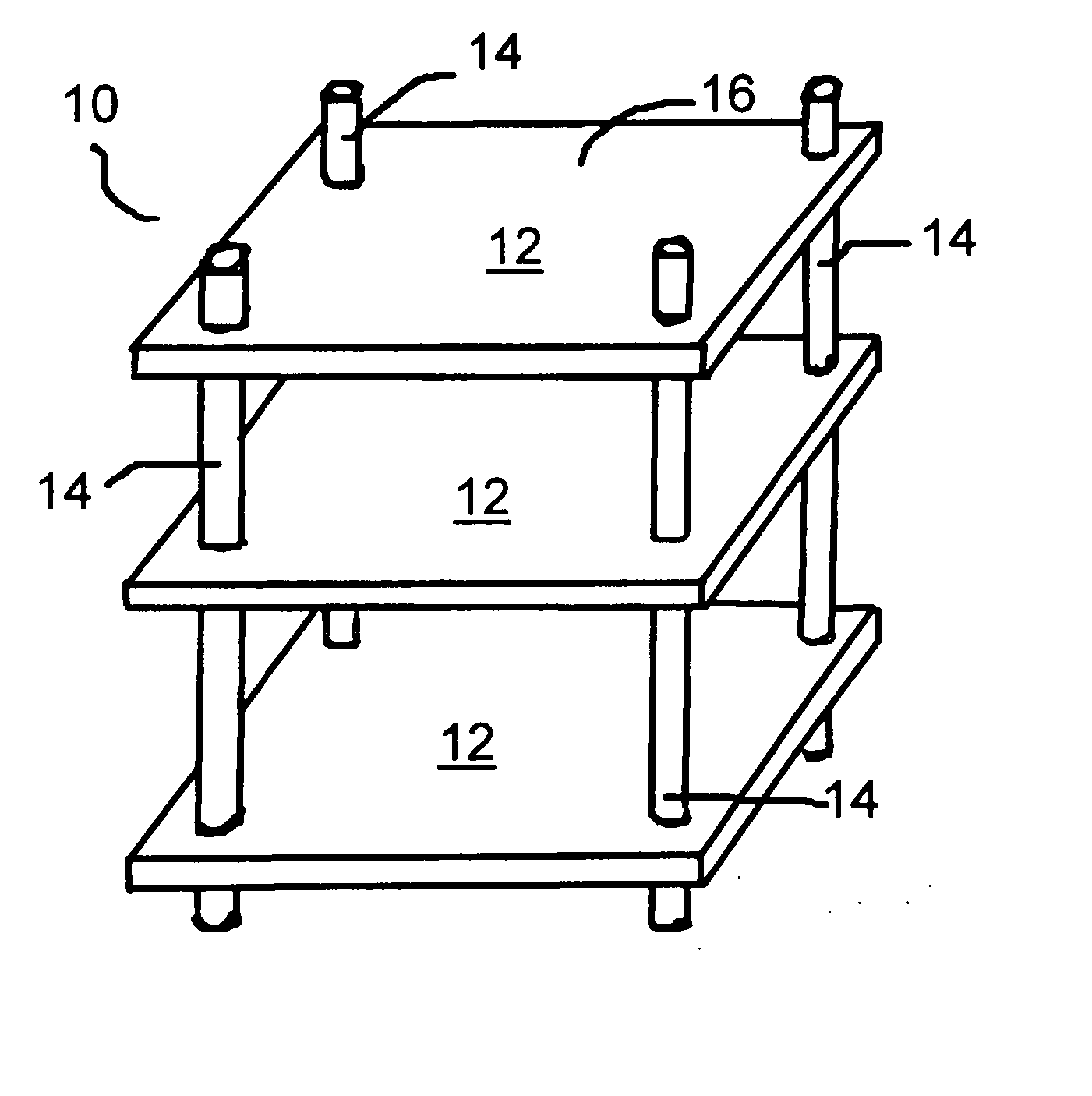

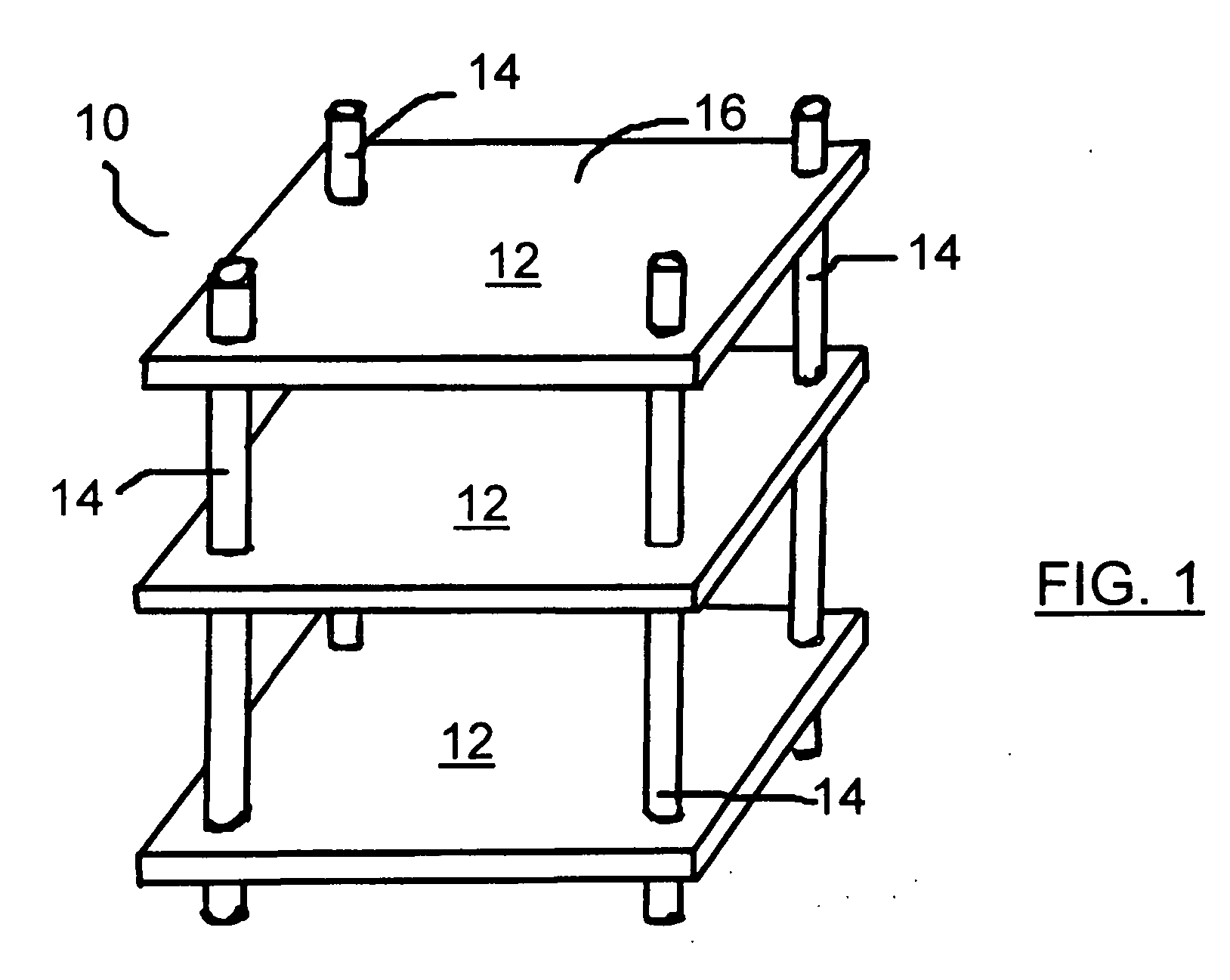

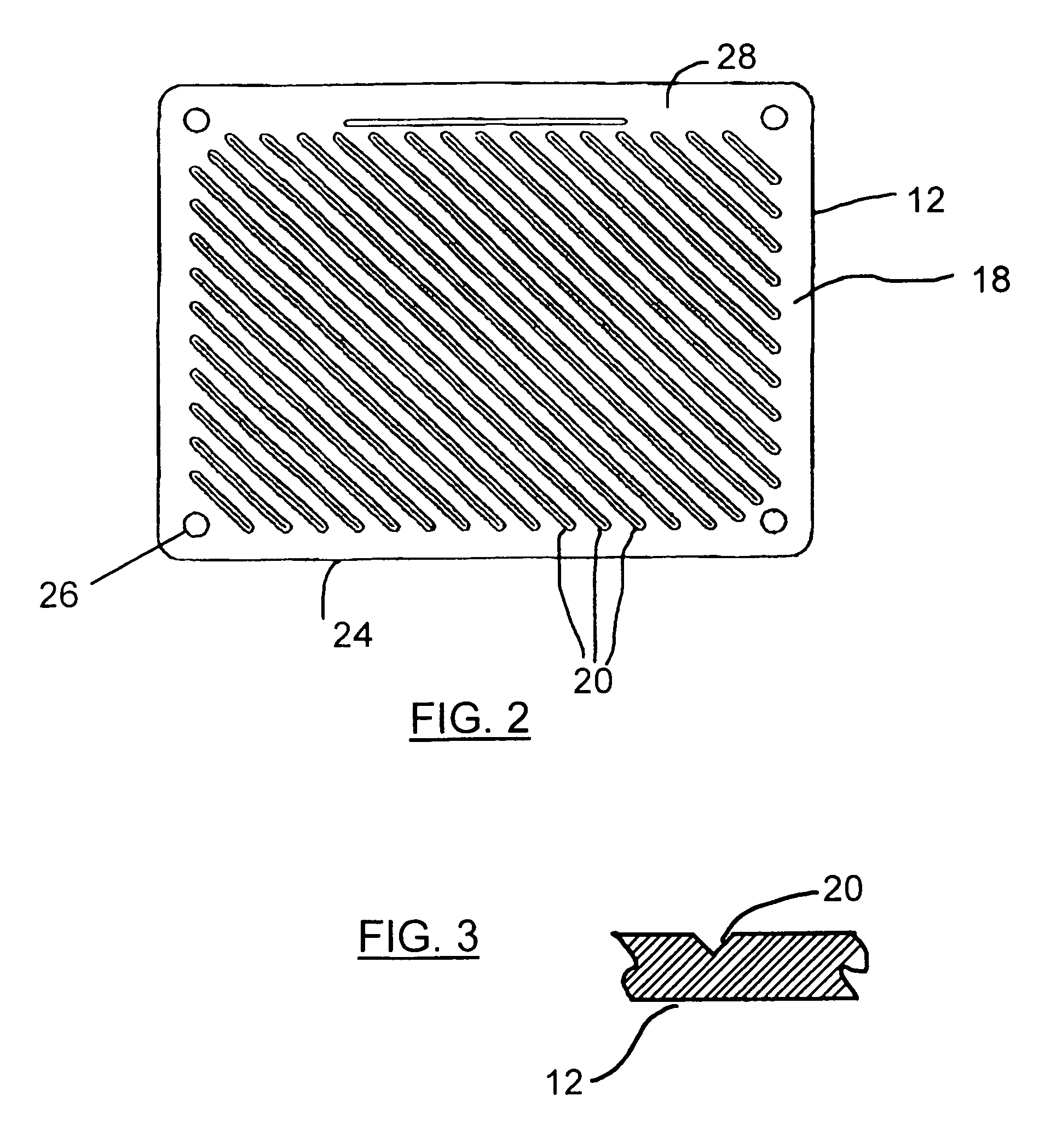

[0067] A series of support configurations were tested to evaluate the propagation of vibration within the stand.

Testing Parameters

[0068] Since every electronic component used for the subjective listening tests was receiving a 60 Hz, 117 V electrical input, the test frequencies chosen were multiples of 60 Hz. As such, the test frequencies used were 60 Hz, 120 Hz, 240 Hz, 600 Hz, 1200 Hz, 3000 Hz, and 6000 Hz.

[0069] To increase the likelihood of finding significant differences in vibration response between different test racks, instead of merely varying the input AC frequency, a loudspeaker was placed on the top shelf, with the drivers facing directly downward. This loudspeaker (System-Audio S2K) consisted of a tweeter and a mid-bass driver. It was supported by a two-piece stabilizing cone / spike on each corner. The location of each cone / spike was consistent for each test rack configuration. As a result, both acoustic vibrations and direct mechanical vibrations from the loudspeaker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com