Cooling Apparatus of Looped Heat Pipe Structure

a cooling apparatus and looped heat pipe technology, applied in lighting and heating apparatus, cooling/ventilation/heating modification, indirect heat exchangers, etc., can solve the problems of reduced cooling capability, reduced reliability of semiconductor devices, and limitations of improved conventional cooling methods, so as to improve cooling functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, a cooling apparatus of a looped heat pipe structure in accordance with certain embodiments of the present invention will be described in detail with reference to the accompanying drawings. Also, it should be noted that the same reference numerals are used for the same configuration elements even in different drawings.

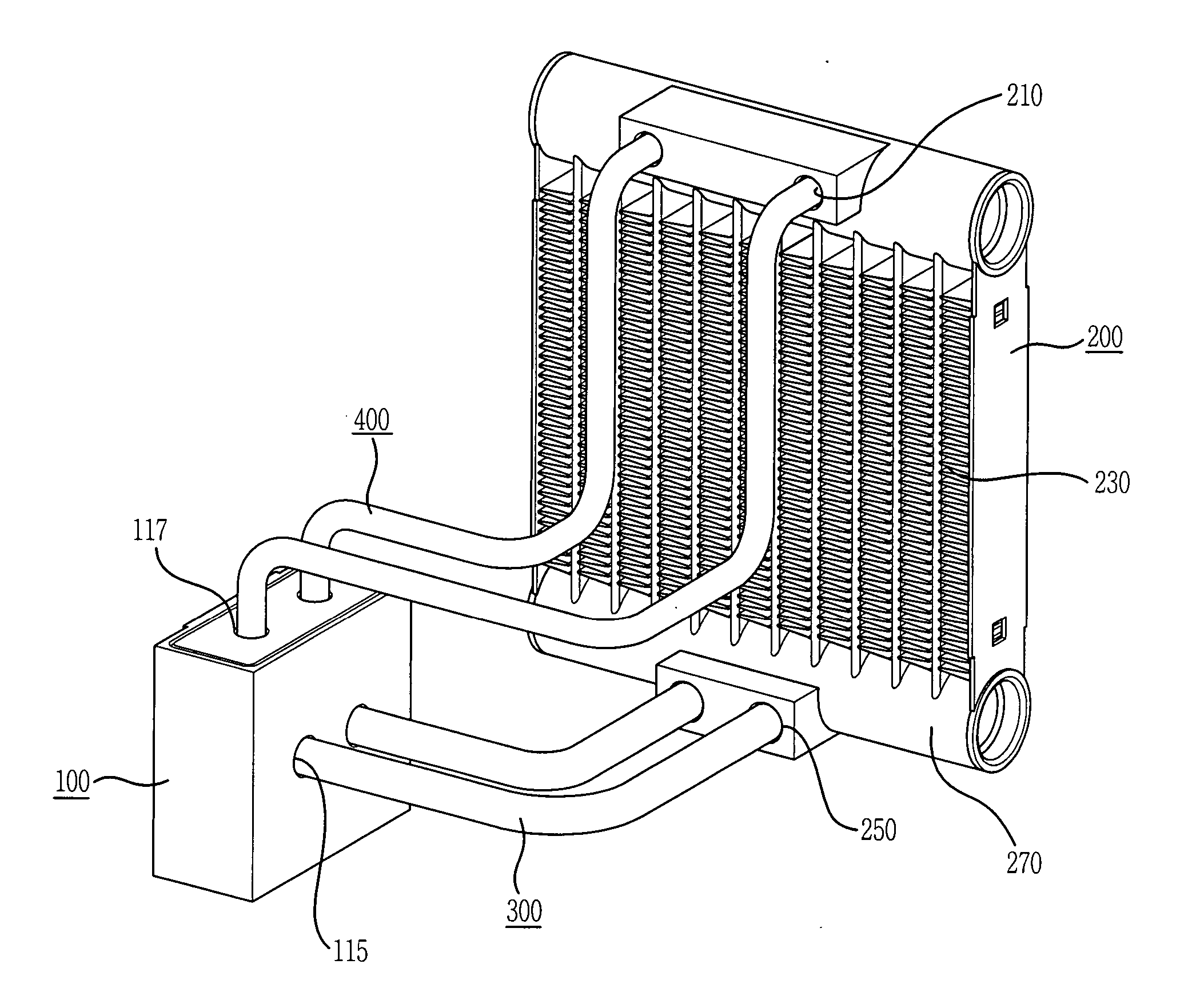

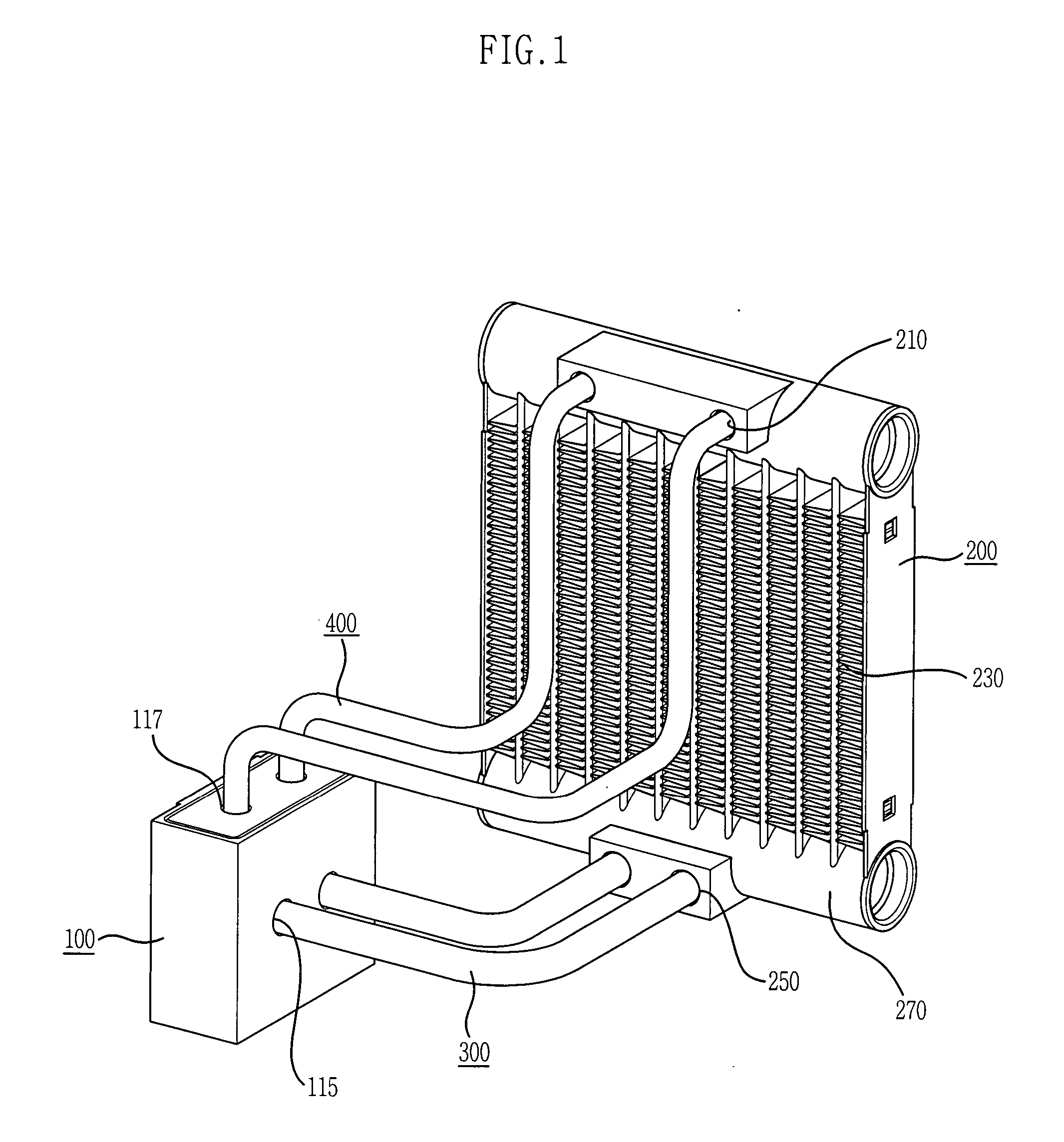

[0056]FIG. 1 is a perspective view showing a cooling apparatus with a looped heat pipe structure in accordance with a specific embodiment of the present invention.

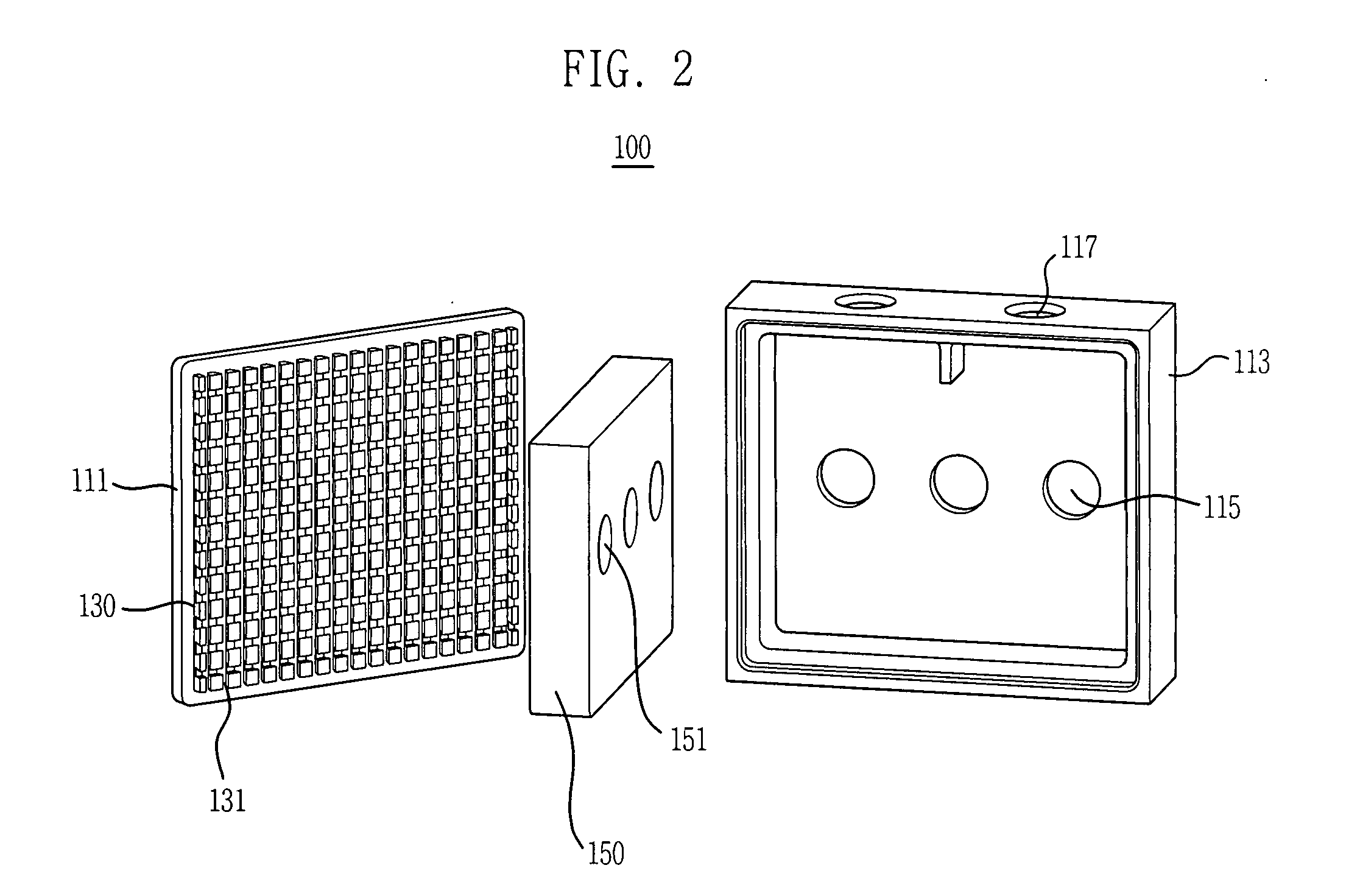

[0057] As shown, the cooling apparatus includes: an evaporator 100 disposed closely to a heat emitter which is a high temperature unit; a condenser 200 disposed at a low temperature unit side; at least one gaseous coolant pipe 400 connecting at least one gaseous coolant outlet 117 of the evaporator 100 with at least one inlet 210 of the condenser 200; at least one liquid coolant pipe 300 connecting at least one outlet 250 of the condenser 200 with at least one liquid coolant inlet 115 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com