Method and apparatus for preheating ventilation air for a building

a technology for ventilation air and buildings, applied in lighting and heating apparatus, heating types, sustainable buildings, etc., can solve problems such as pressure drop in air flow, and achieve the effects of improving ventilation efficiency, simple and easy installation, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

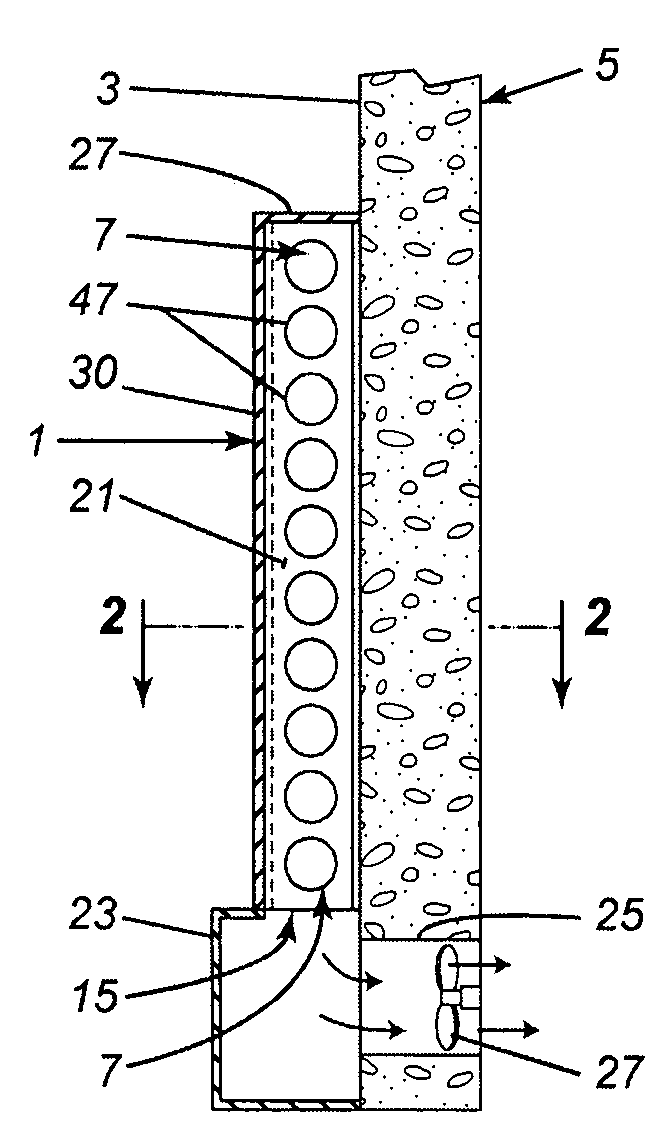

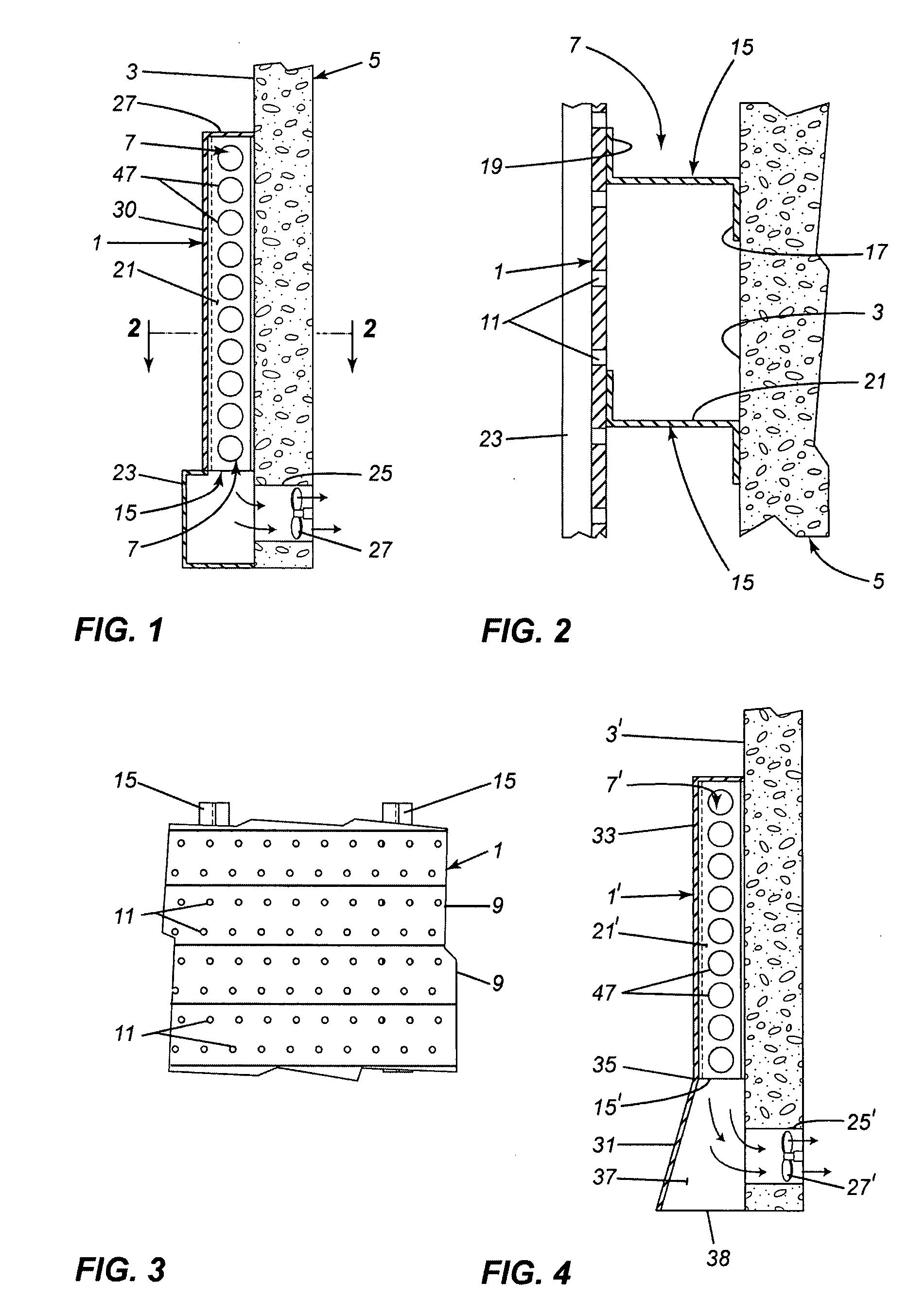

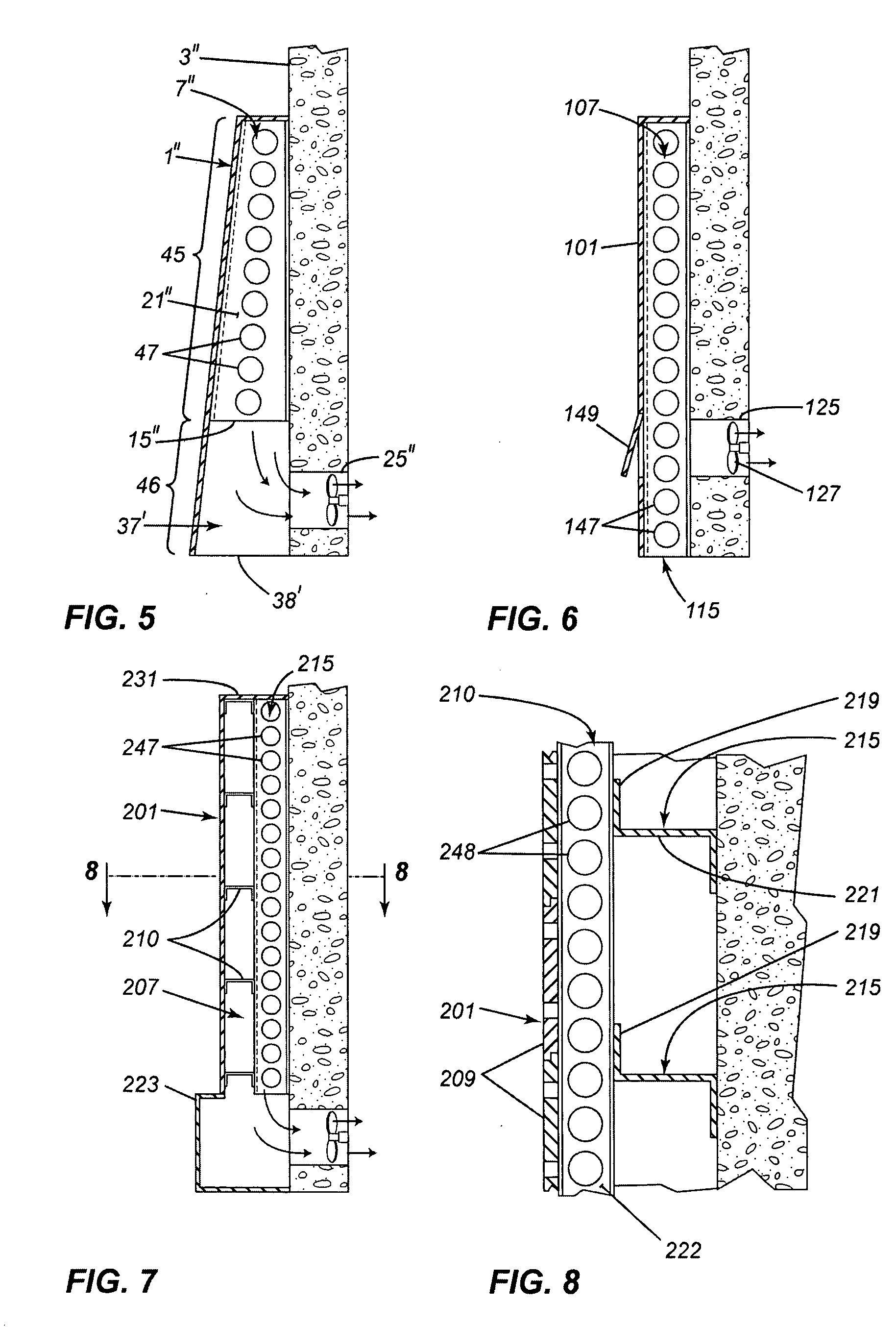

[0024]The solar air heating system, as shown in FIGS. 1-3, has a perforated, heat-absorbing panel 1 mounted on a south facing wall 3 of a building 5. The panel could be coated on its outside surface with a black paint to make it heat absorbing. The panel 1 is spaced a short distance from the wall 5 to form an air channel 7. The panel 1 can be made up of a plurality interlocked siding members 9, the siding members mounted horizontally on the building 5. The siding members 9 have circular perforations 11 therein, the perforations 11 normally equally spaced apart. The perforations 11 are about 0.0625 inches in diameter and there are about 3 to 8 perforations per square inch of panel but the size and density of perforations can vary depending on the amount of air required to be added to the building for heating or ventilation purposes.

[0025]To mount the siding members 9 horizontally to form the panel 1, a plurality of vertical frame members 15, horizontally spaced apart, are used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com