Temperature History Indicator

a technology of temperature history and indicator, which is applied in the direction of chemical indicators, instruments, chemical methods analysis, etc., can solve the problems of low temperature history indicators that are inferior in visibility for temperature history, liquid leakage may occur, etc., and achieve low cost, easy detection of temperature history, and easy control of goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Preparation Examples

[0106] Hereinafter, suitable examples and comparative examples of a temperature history indicator according to the present invention will be specifically explained further with reference to preparation examples 1 to 9, but the present invention is not limited by these preparation examples.

preparation example 1

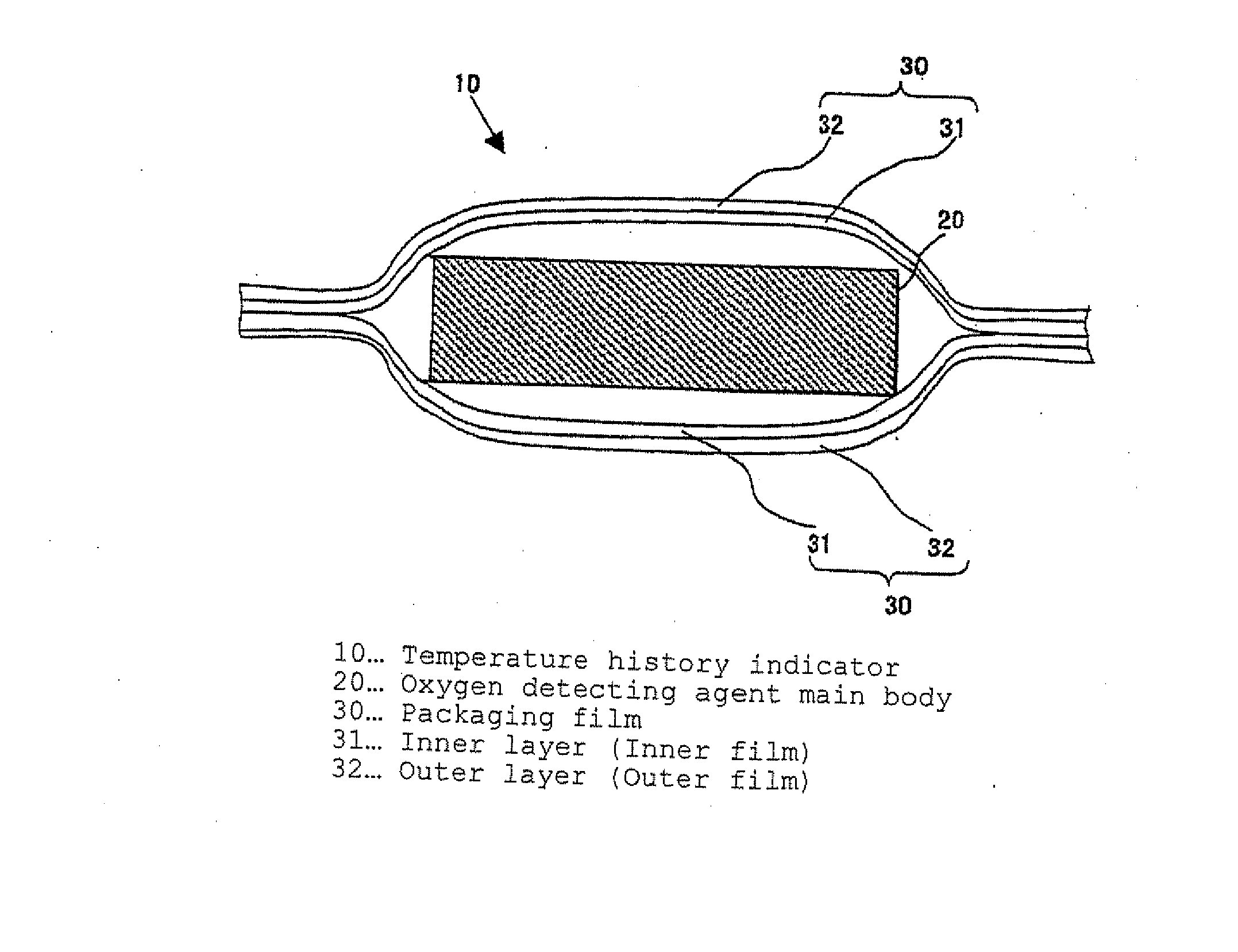

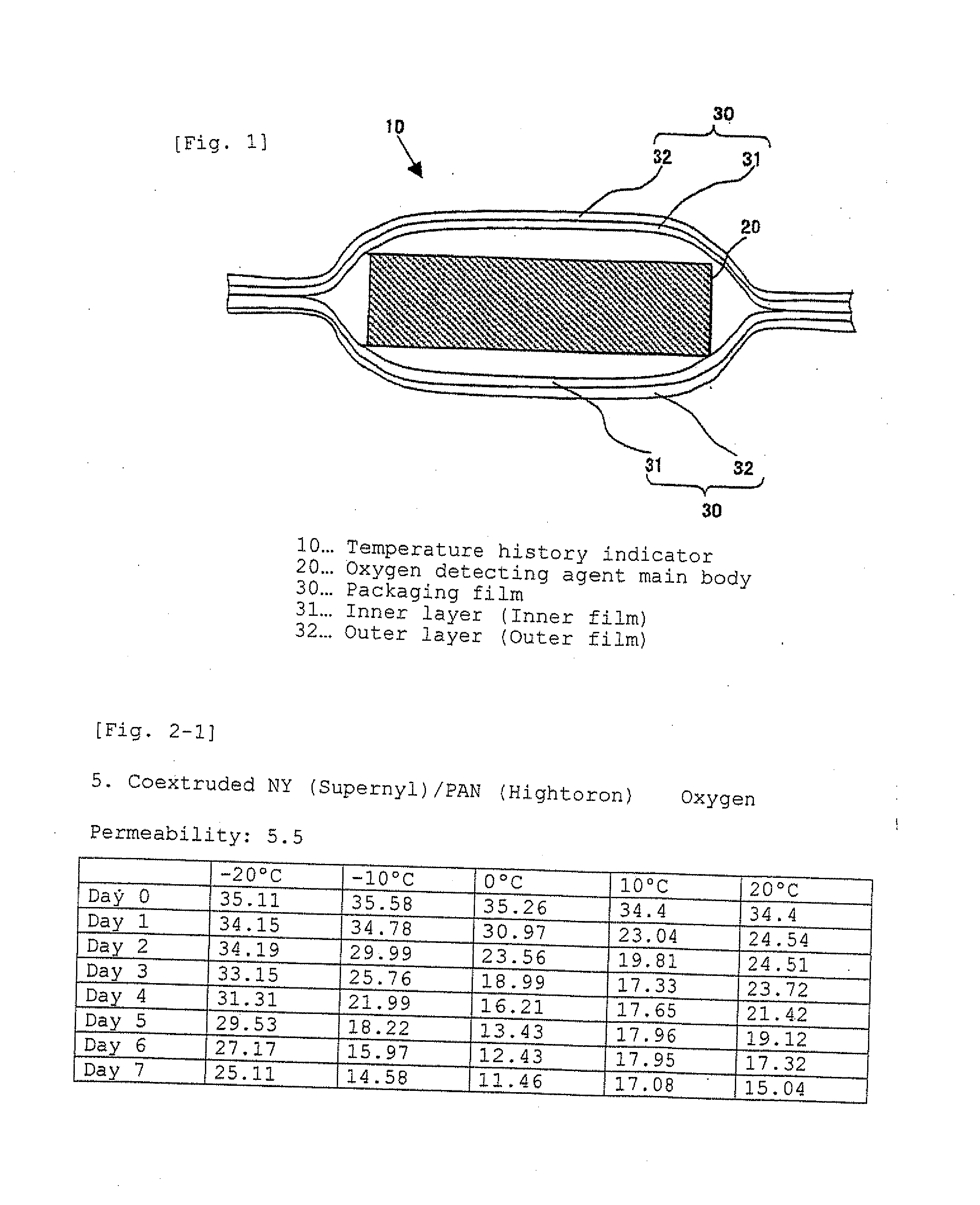

[0107] [Temperature History Indicator (No. 5)>

[0108]20>

[0109] An oxygen detecting agent main body 20 was prepared in accordance with examples 3 and 4 of Japanese Patent Laid-Open Publication No S63-243754.

[0110] That is, a mixed solution was prepared by mixing 13 parts by weight of a 0.5% methylene blue solution, 13 parts by weight of a 0.25% Safranine T solution, 65 parts by weight of 30% D-glucose and 9 parts by weight of a 15% potassium hydroxide solution and the resulting mixed solution was impregnated in a filter paper (“example 3” in the same patent application). In addition, thereafter, the filter paper was vacuum dried to remove the unnecessary moisture where necessary (“example 4” in the same patent publication).

[0111] The oxygen detecting agent main body 20 described in example 4 of this patent publication changed in color to pink when it was maintained under a nitrogen atmosphere (the oxygen concentration: not more than 0.1%) and developed a blue color when oxygen of mo...

preparation example 2

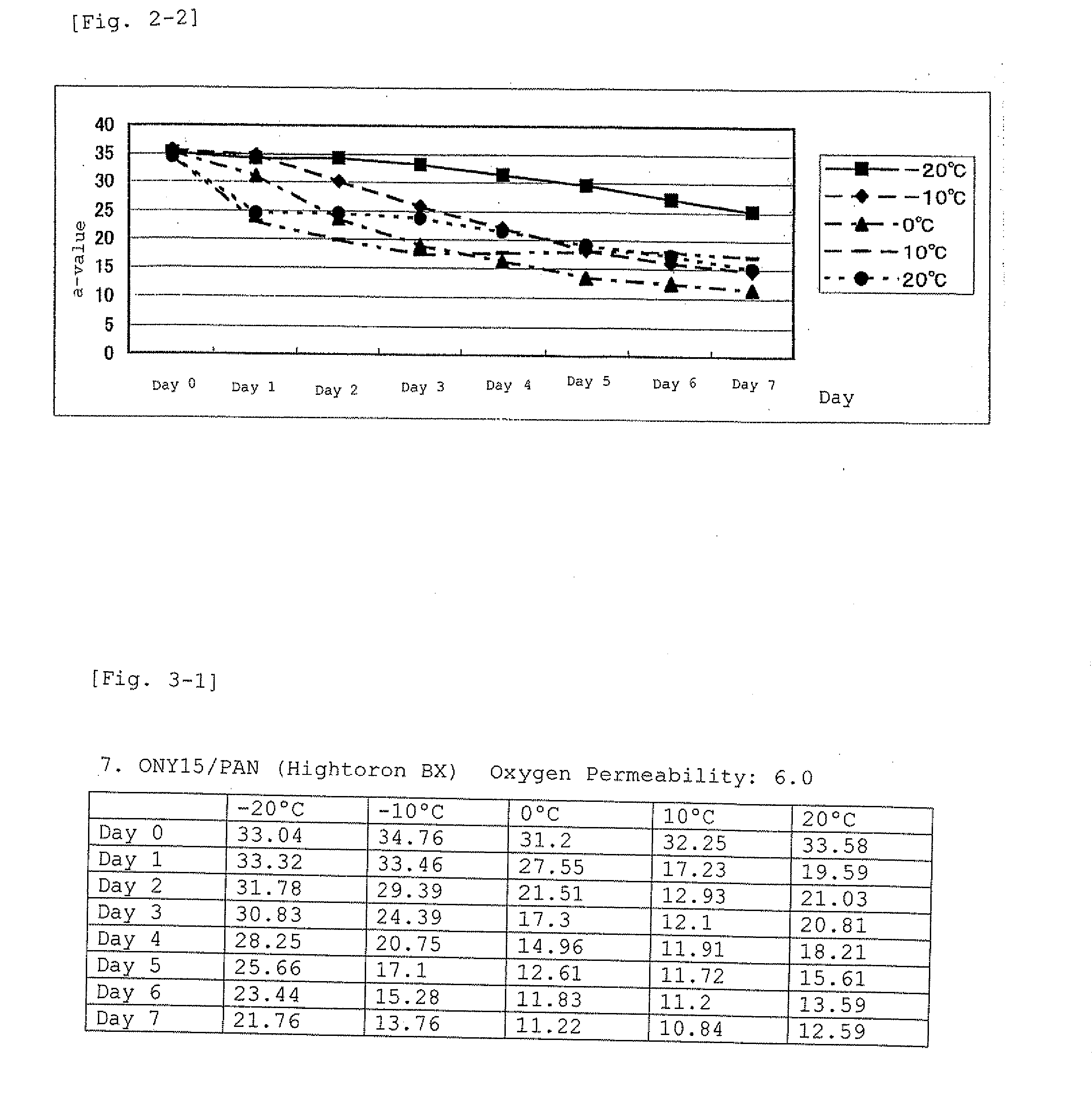

[0125] [Temperature History Indicator (No. 7)>

[0126] A temperature history indicator was prepared similarly to preparation example 1 except that the following biaxially stretched polyamide (ONY 15) / polyacrylonitrile (PAN) laminated film (D) was used as the packaging film 30 in preparation example 1 and was tested in a similar way.

[0127] The results are shown in FIG. 3-1 and FIG. 3-2.

[0128] The details of preparation example 2 are as follows.

[0129]20>

[0130] The oxygen detecting agent main body 20 was prepared in accordance with examples 3 and 4 of Japanese Patent Laid-Open Publication No. S63-243754.

[0131] That is, a mixed solution was prepared by mixing 13 parts by weight of a 0.5% methylene blue solution, 13 parts by weight of a 0.25% Safranine T solution, 65 parts by weight of 30% D-glucose and 9 parts by weight of a 15% potassium hydroxide solution and the resulting mixed solution was impregnated in a filter paper (“example 3” in the same patent publication). In addition, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com