Multi-Pane Window Assembly With Two-Sided Frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

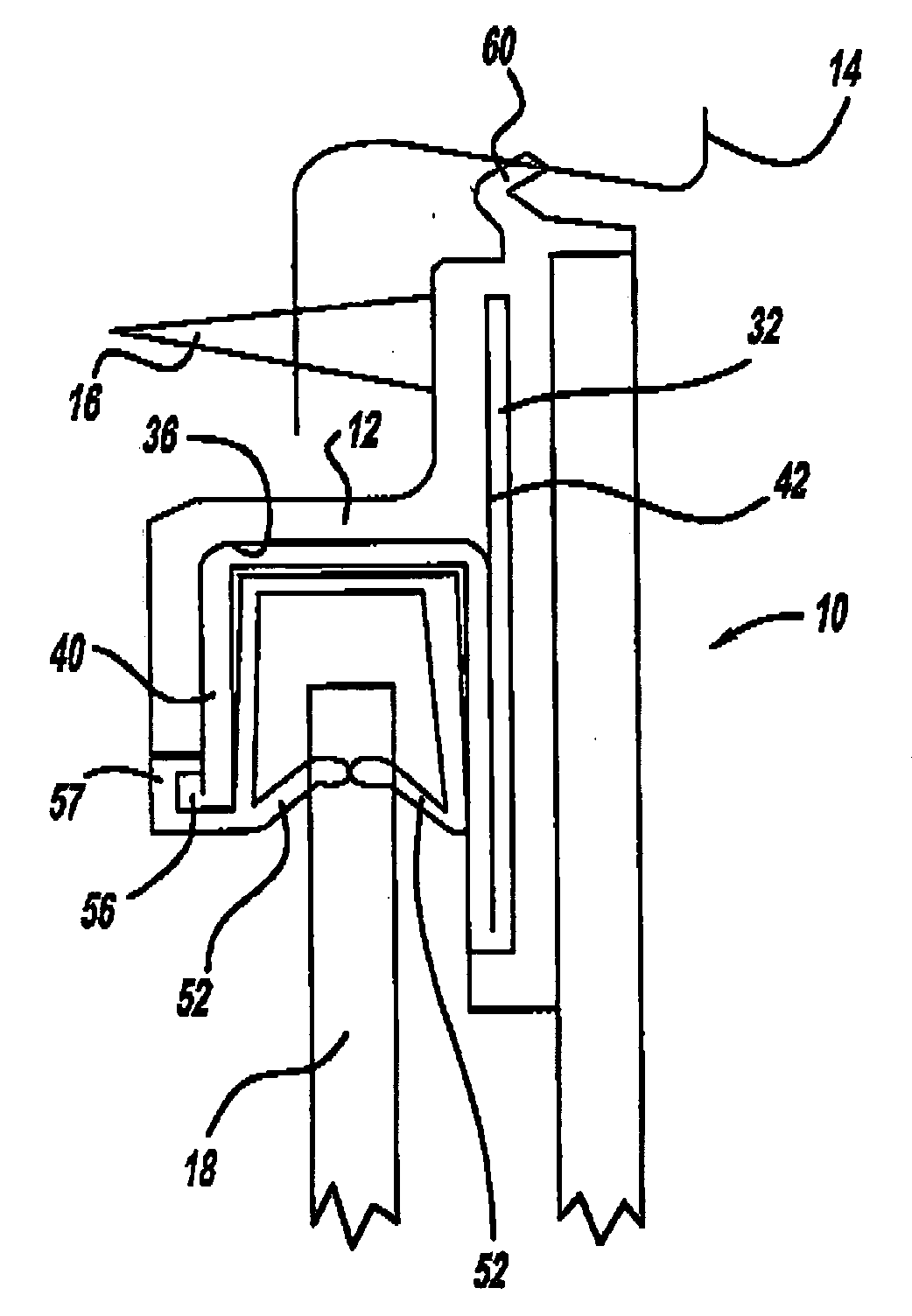

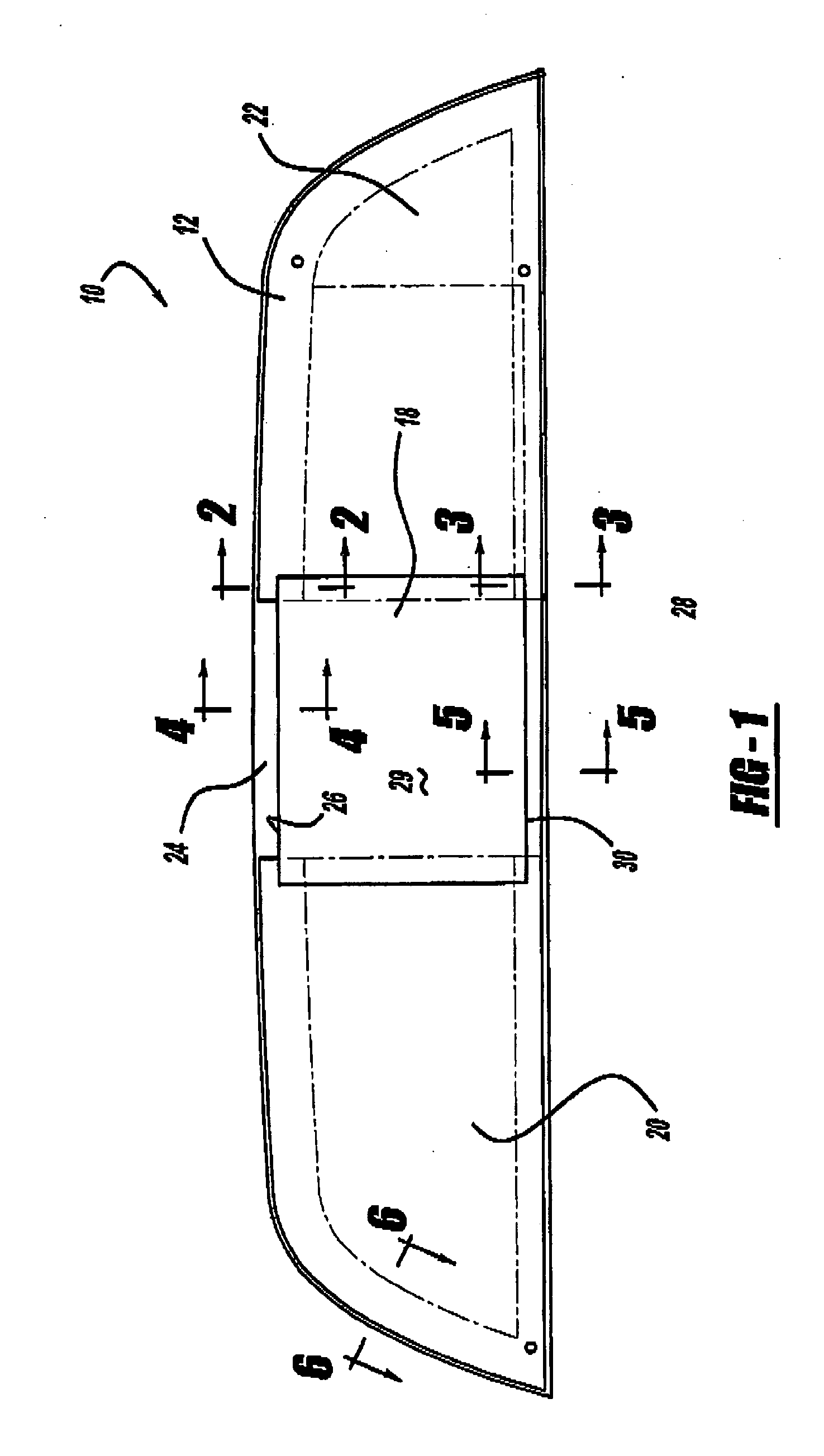

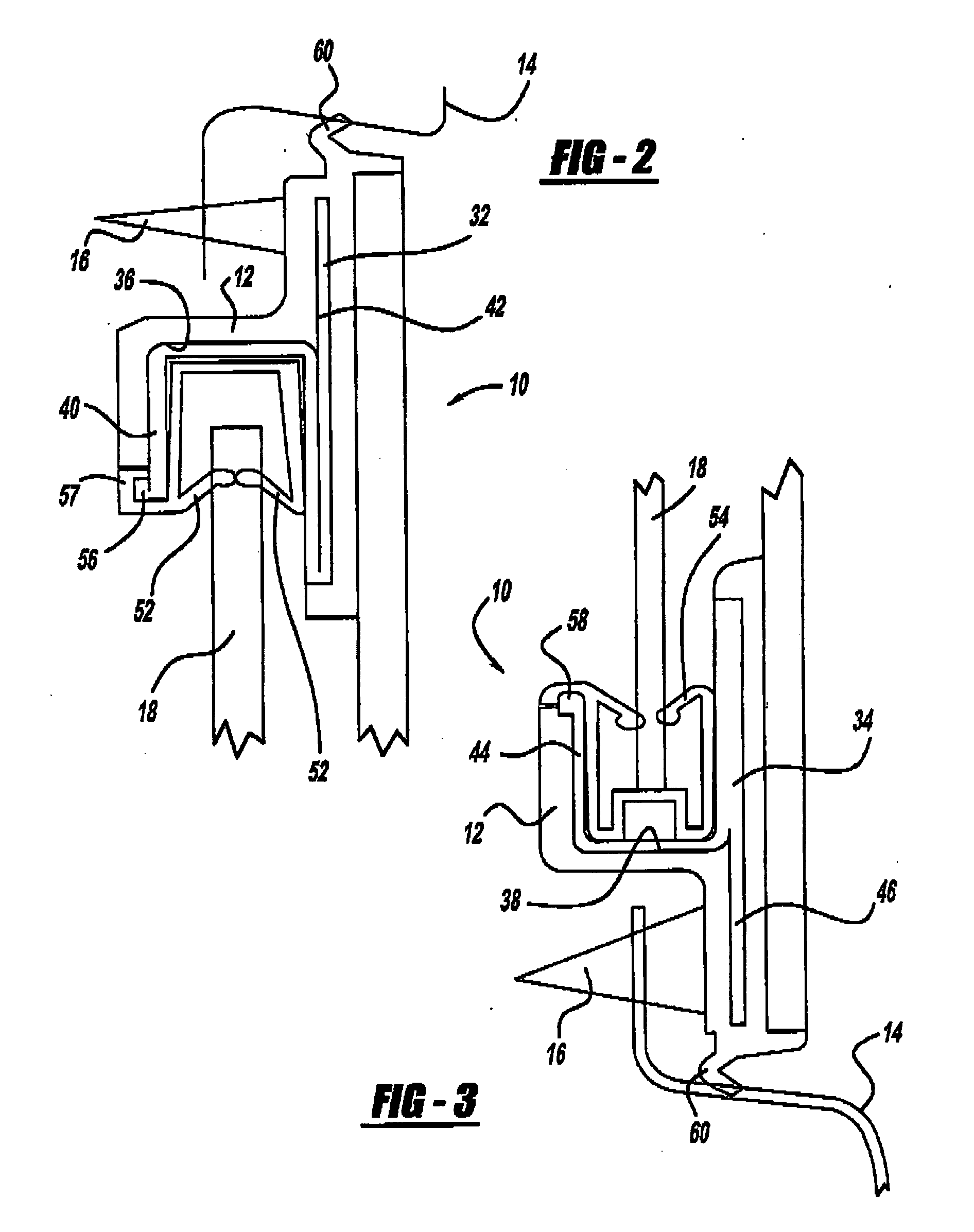

[0028]Window assemblies of the invention will have configurations and components determined, in part, by the intended application and use environment. References to direction and position, unless otherwise indicated, refer to the orientation of the window assembly in the drawing under discussion. In general, “exterior” refers to a direction or position outwardly of the space enclosed by the wall or structure in which the window is installed, e.g., outside the passenger compartment of a motor vehicle. Correspondingly, “inward” or “interior” refers to a direction in or into the passenger compartment or other such space. The term “inboard” is used here (i.e., in this description of the disclosed window assemblies and in the appended claims) to describe a lateral position or location, e.g., the location of the vertical edge of a fixed or stationary pane which is proximate to the slider pane. As viewed in FIG. 1, for example, inboard refers to the lateral position of a feature, i.e., the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com