Plasma display panel and field emission display

a display panel and field emission technology, applied in the field of plasma display panel and field emission display, can solve the problems of insufficient anti-reflection function of cone-shaped or pyramid-shaped anti-reflection structure, difficult to perform anti-reflection treatment of all incident lights from external, etc., to achieve high anti-reflection function, diffuse light, and increase the amount of incident light from external entering the pyramidal projection of the anti-reflection layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

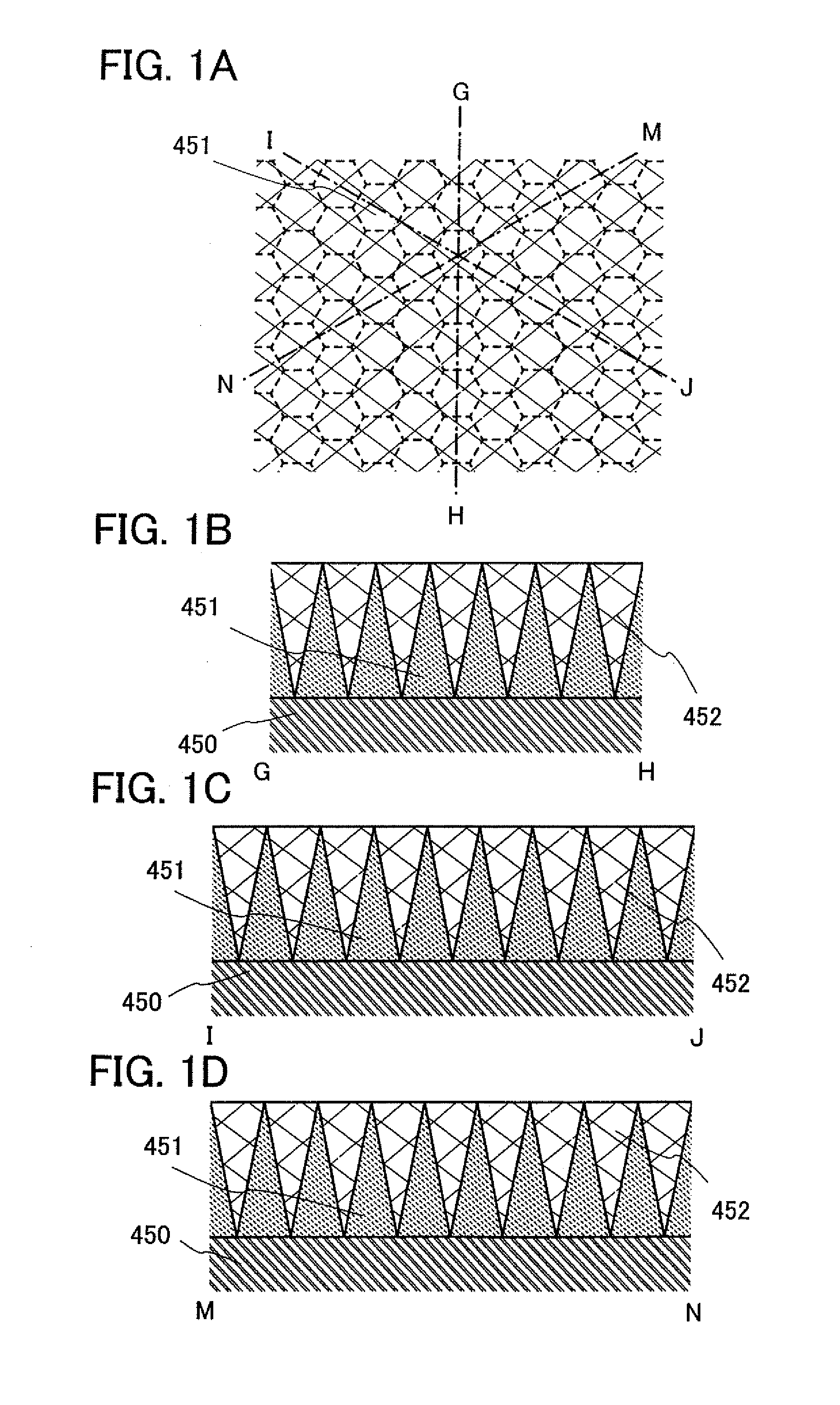

[0053]In this embodiment mode, an example of an anti-reflection layer for the purpose of having an anti-reflection function that can further reduce reflection of incident light from external and increasing visibility will be described.

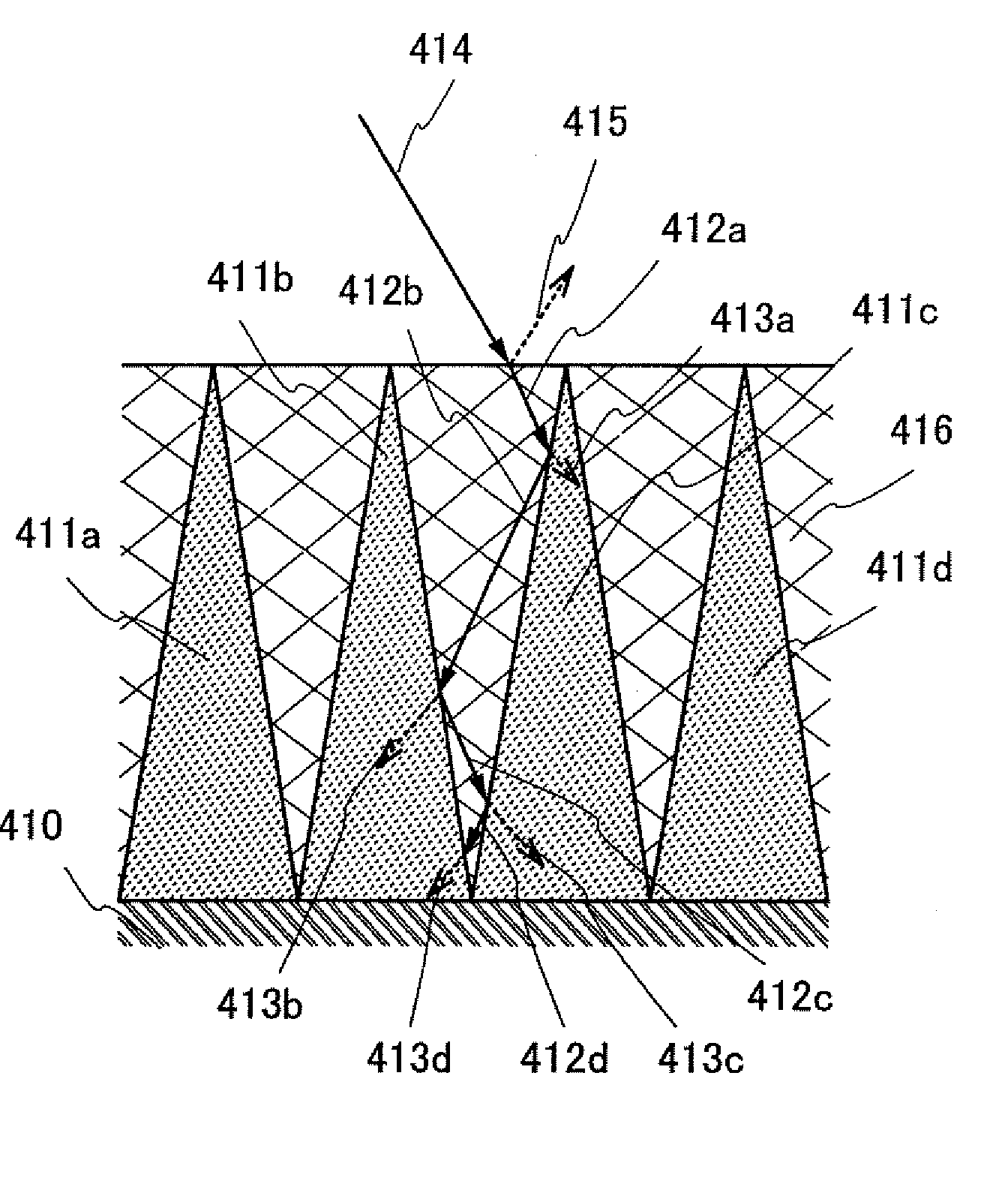

[0054]FIG. 1A shows a top view of an anti-reflection layer of this embodiment mode that uses the present invention, and FIGS. 1B to 1D each show a cross-sectional view of an anti-reflection layer of this embodiment mode that uses the present invention. In FIGS. 1A to 1D, a plurality of hexagonal pyramidal projections 451 and a protective layer 452 are provided over a substrate that is to serve as a display screen of a PDP or an FED 450. The anti-reflection layer is formed of the plurality of hexagonal pyramidal projections 451 and the protective layer 452. FIG. 1A is a top view of a PDP or an FED of this embodiment mode. FIG. 1B is a cross-sectional view taken along line G-H from FIG. 1A. FIG. 1C is a cross-sectional view taken along line I-J from FIG....

embodiment mode 2

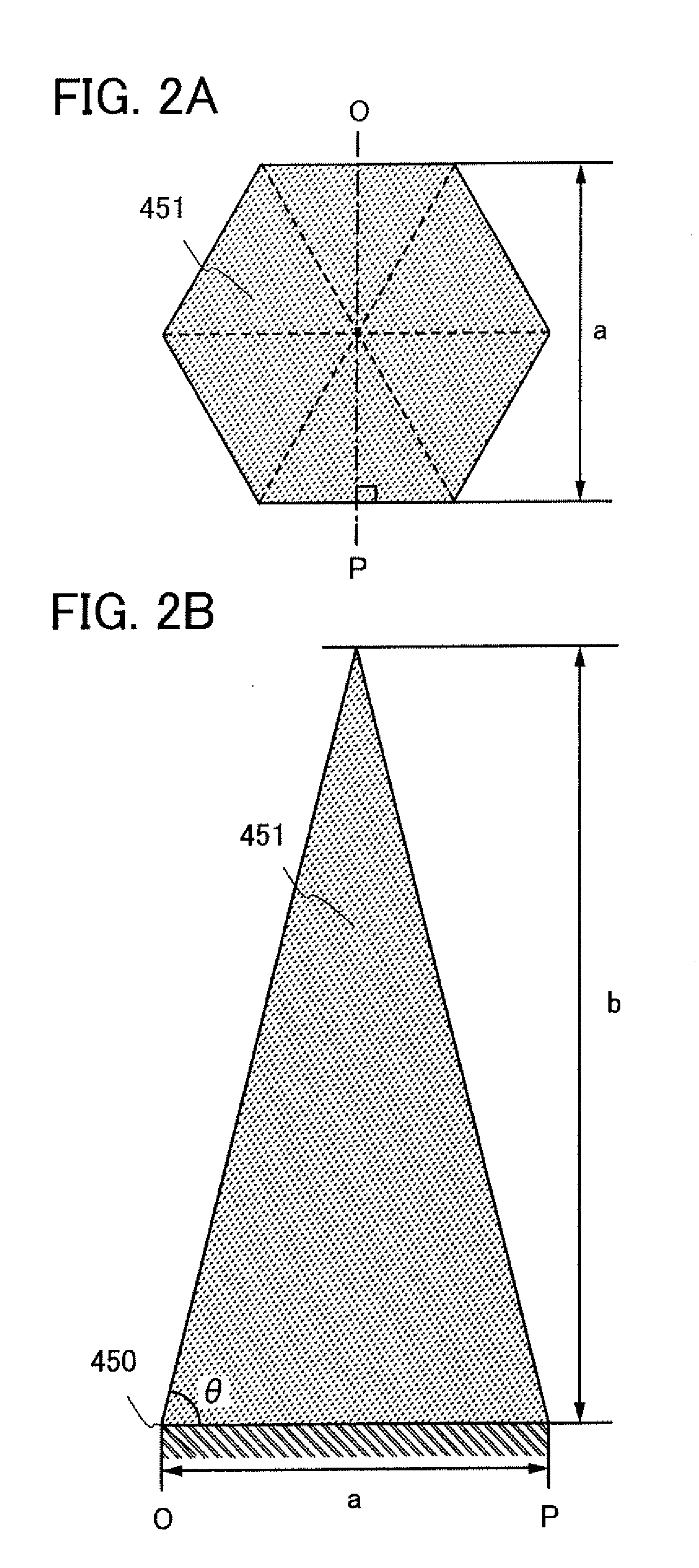

[0095]In this embodiment mode, an example of a PDP for the purpose of having an anti-reflection function that can further reduce reflection of incident light from external and increasing visibility will be described. That is, a structure of a PDP including a pair of substrates, a pair of electrodes provided between the pair of substrates, a phosphor layer provided between the pair of electrodes, and an anti-reflection layer provided on an outer side of one substrate of the pair of substrates will be described in detail.

[0096]In this embodiment mode, a surface emission PDP of an alternating current discharge type (an AC type) is shown. As shown in FIG. 9, in a PDP, a front substrate 110 and a back substrate 120 are placed facing each other, and the periphery of the front substrate 110 and the back substrate 120 is sealed with a sealant (not shown). In addition, a region enclosed by the front substrate 110, the back substrate 120, and the sealant is filled in with a discharge gas.

[009...

embodiment mode 3

[0148]In this embodiment mode, an FED for the purpose of having an anti-reflection function that can further reduce reflection of incident light from external and increasing visibility will be described. That is, a structure of an FED including a pair of substrates, a field emission element provided on one substrate of the pair of substrates, an electrode provided on the other substrate of the pair of substrates, a phosphor layer which comes into contact with the electrode, and an anti-reflection layer provided on an outer side of the other substrate will be described in detail.

[0149]The FED is a display device in which a phosphor is exited by an electron beam to emit light. The FED can be classified into a diode FED, a triode FED, and a tetrode FED according to the configuration of electrodes.

[0150]The diode FED has a structure where a rectangular cathode electrode is formed on a surface of a first substrate while a rectangular anode electrode is formed on a surface of a second sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com