Production of optical pulses at a desired wavelength utilizing higher-order-mode (HOM) fiber

a production method and fiber technology, applied in the field of optical pulses at a desired wavelength using higher-ordermode fibers, can solve the problems of limited wavelength tunability, limited multi-photon imaging applications of fiber sources including lasers, and restrict the applicability of lasers, so as to enhance the modal stability of the signal and enhance the modal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

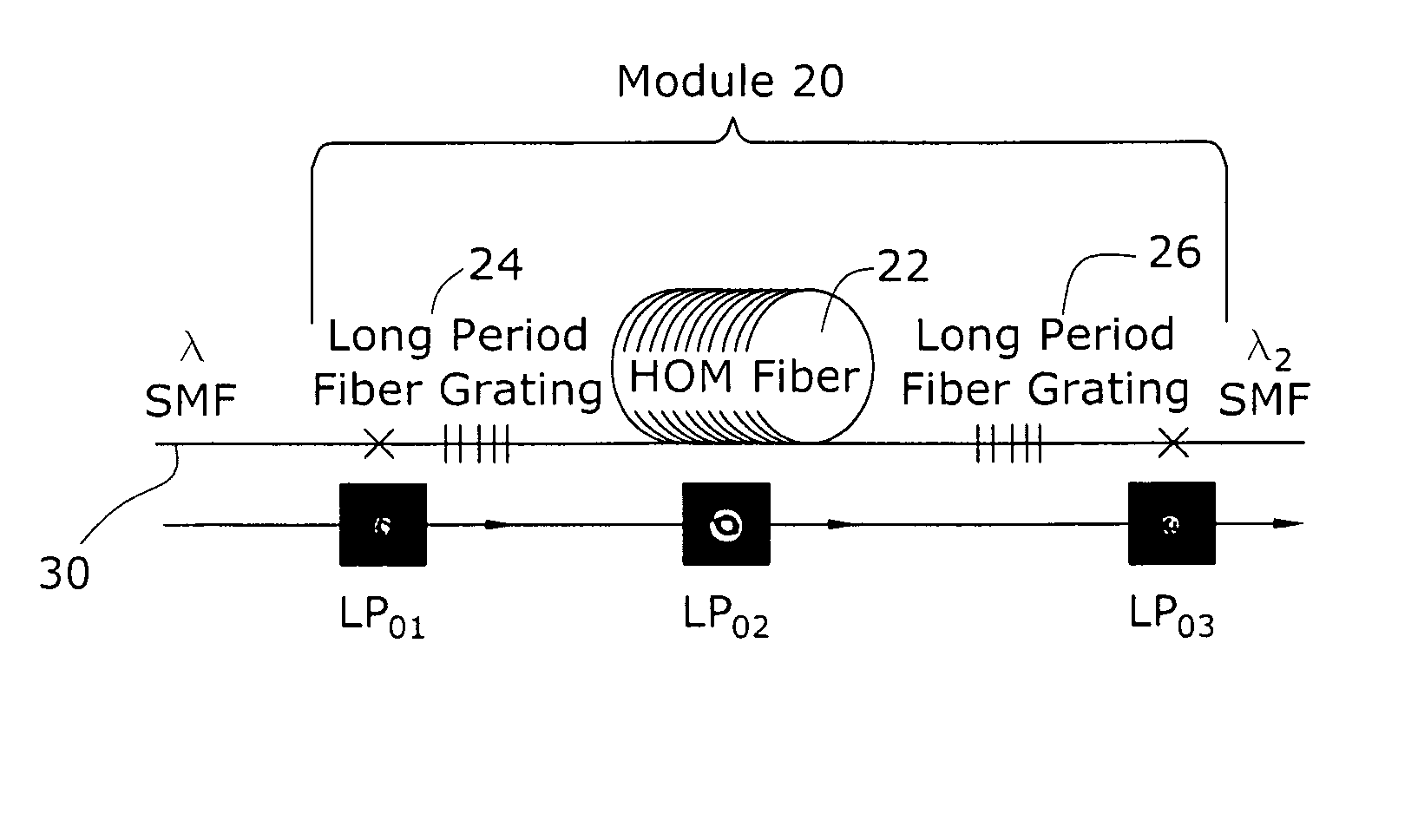

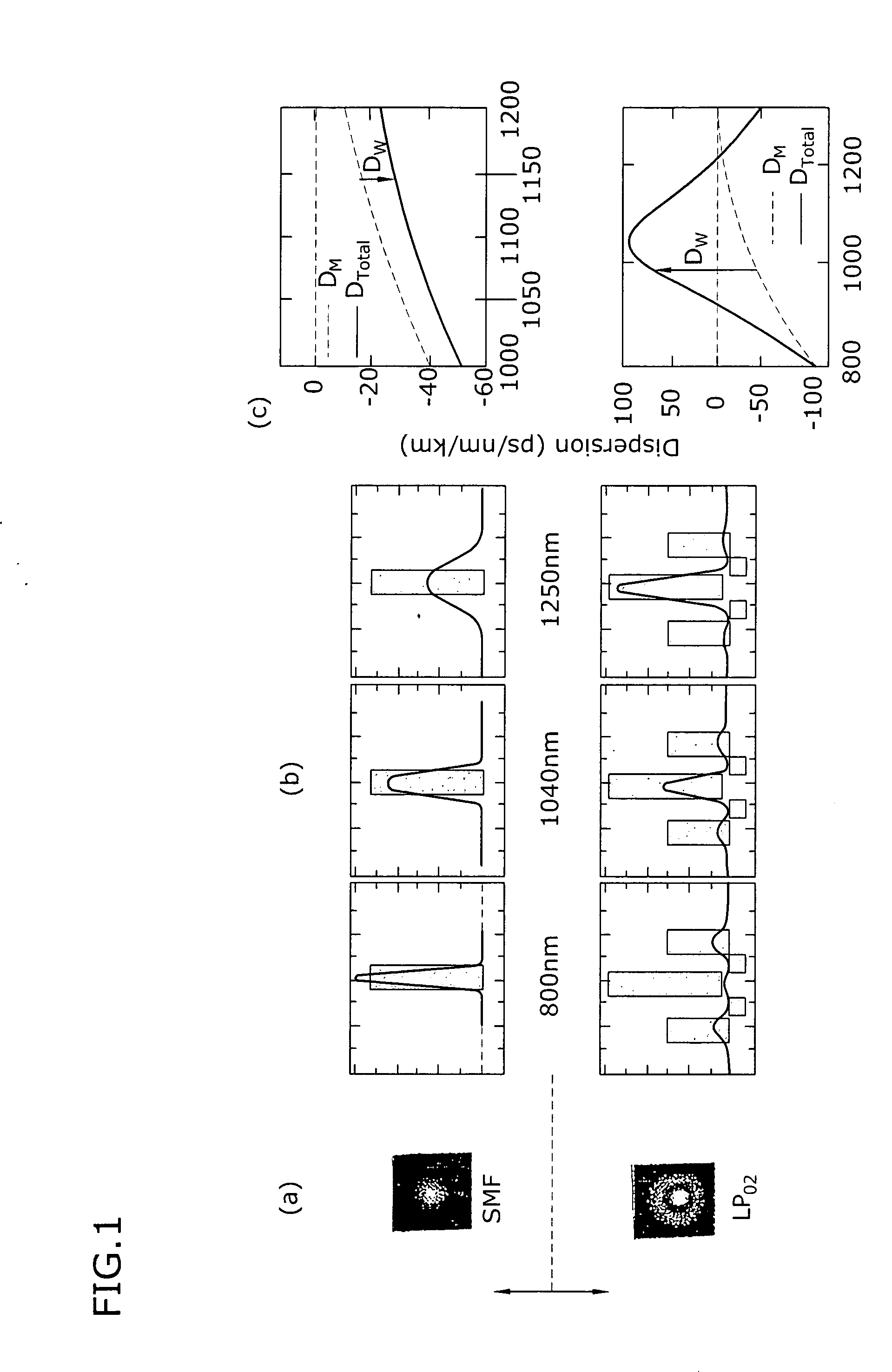

[0030]The present invention is directed to an arrangement for producing high energy, femtosecond output light pulses over a tunable wavelength range for wavelengths less than 1300 nm, using a relatively new type of fiber—higher-order-mode (HOM) fiber—that yields strong anomalous dispersion in the output wavelength range. Advantageously, the HOM fiber is an all-solid silica fiber structure (i.e., does not include air gaps or other microstructures) where the guidance mechanism is conventional index guiding. This represents a major breakthrough in fiber design, inasmuch as it was not previously considered possible to obtain anomalous dispersion at wavelengths shorter than 1300 nm in an all-silica optical fiber.

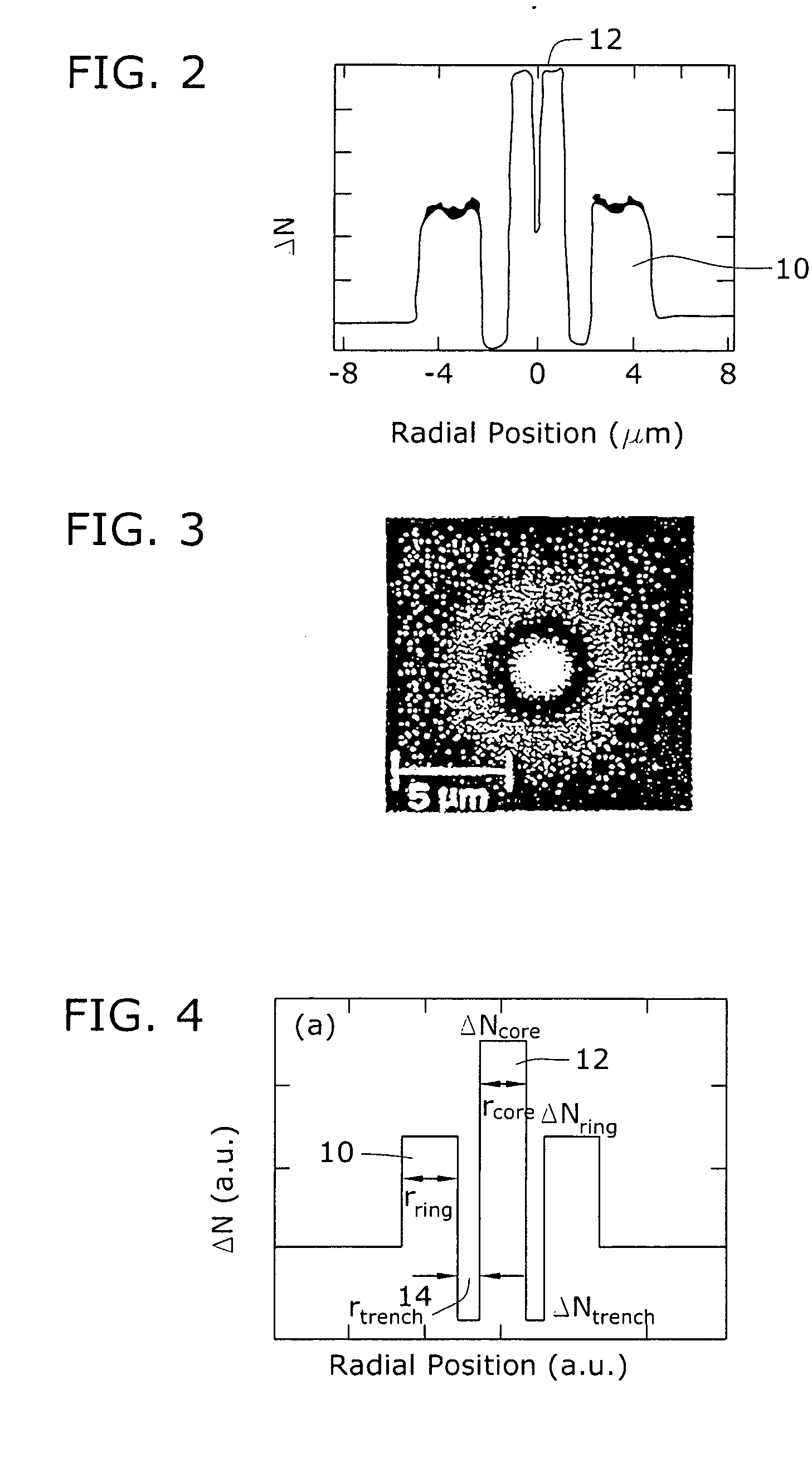

[0031]In accordance with the present invention, a higher-order-mode (HOM) fiber has been developed that is capable of achieving a strong positive (anomalous) waveguide dispersion (Dw) for the LP02 mode at wavelengths less than 1300 nm. In particular, an HOM fiber has been formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelengths | aaaaa | aaaaa |

| pulse energy | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com