Integration schemes for fabricating polysilicon gate mosfet and high-k dielectric metal gate mosfet

a technology of dielectric metal gate mosfet and polysilicon gate mosfet, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problem that the improvement of pmosfet performance may not be sufficient to justify associated incremental cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

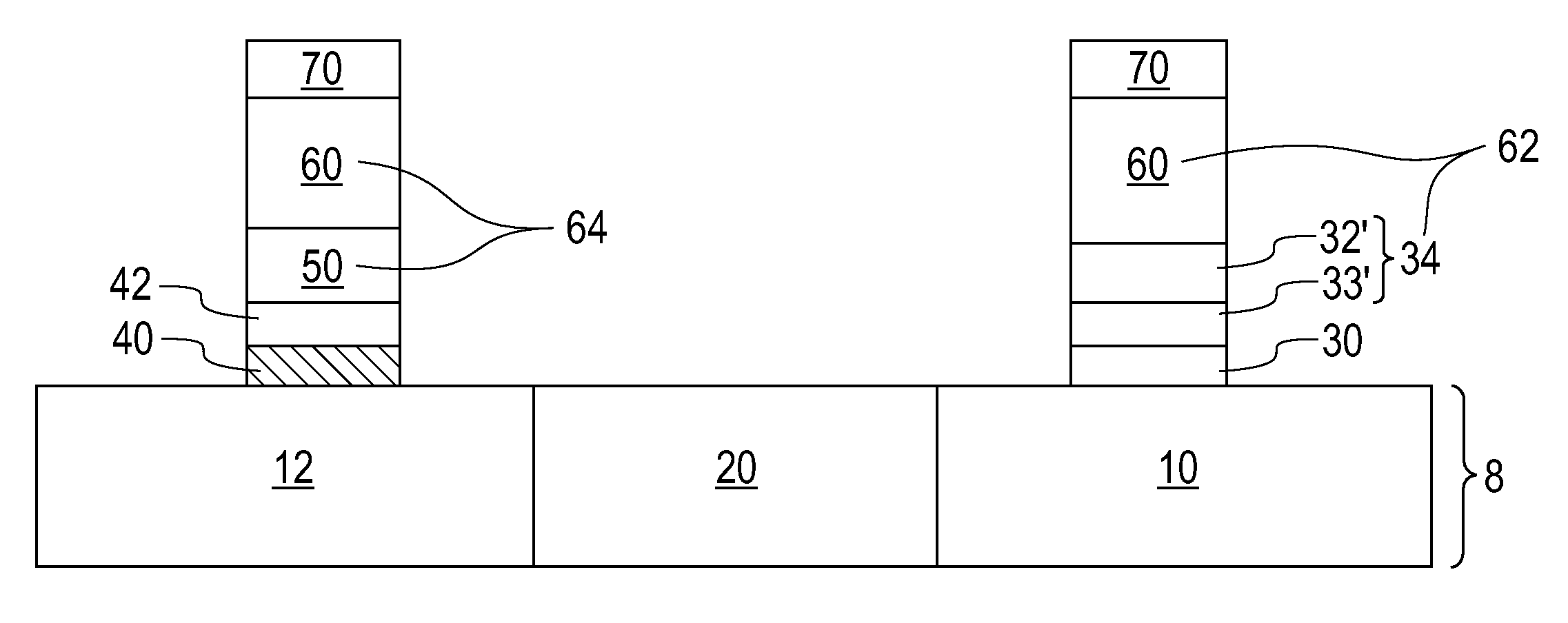

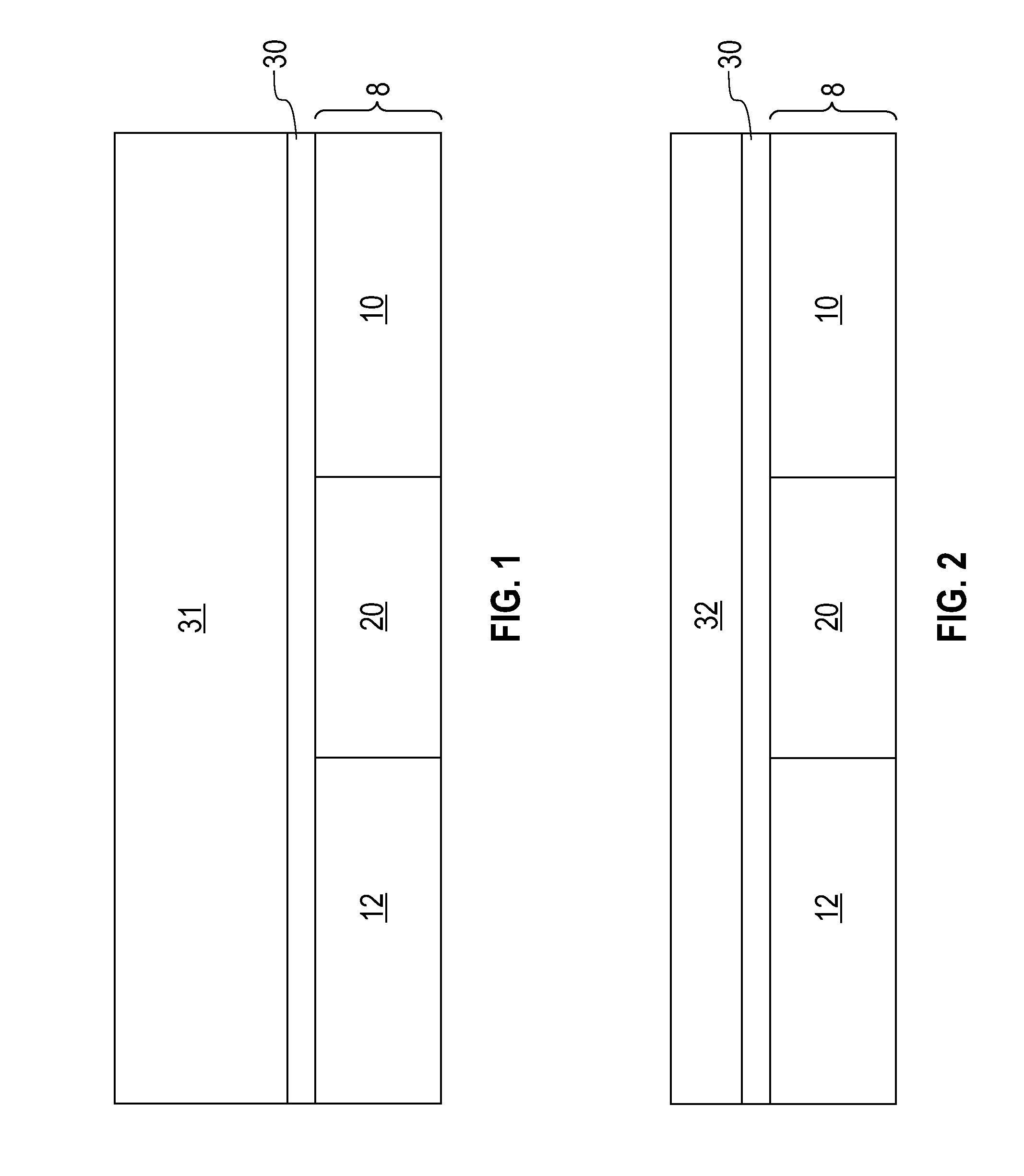

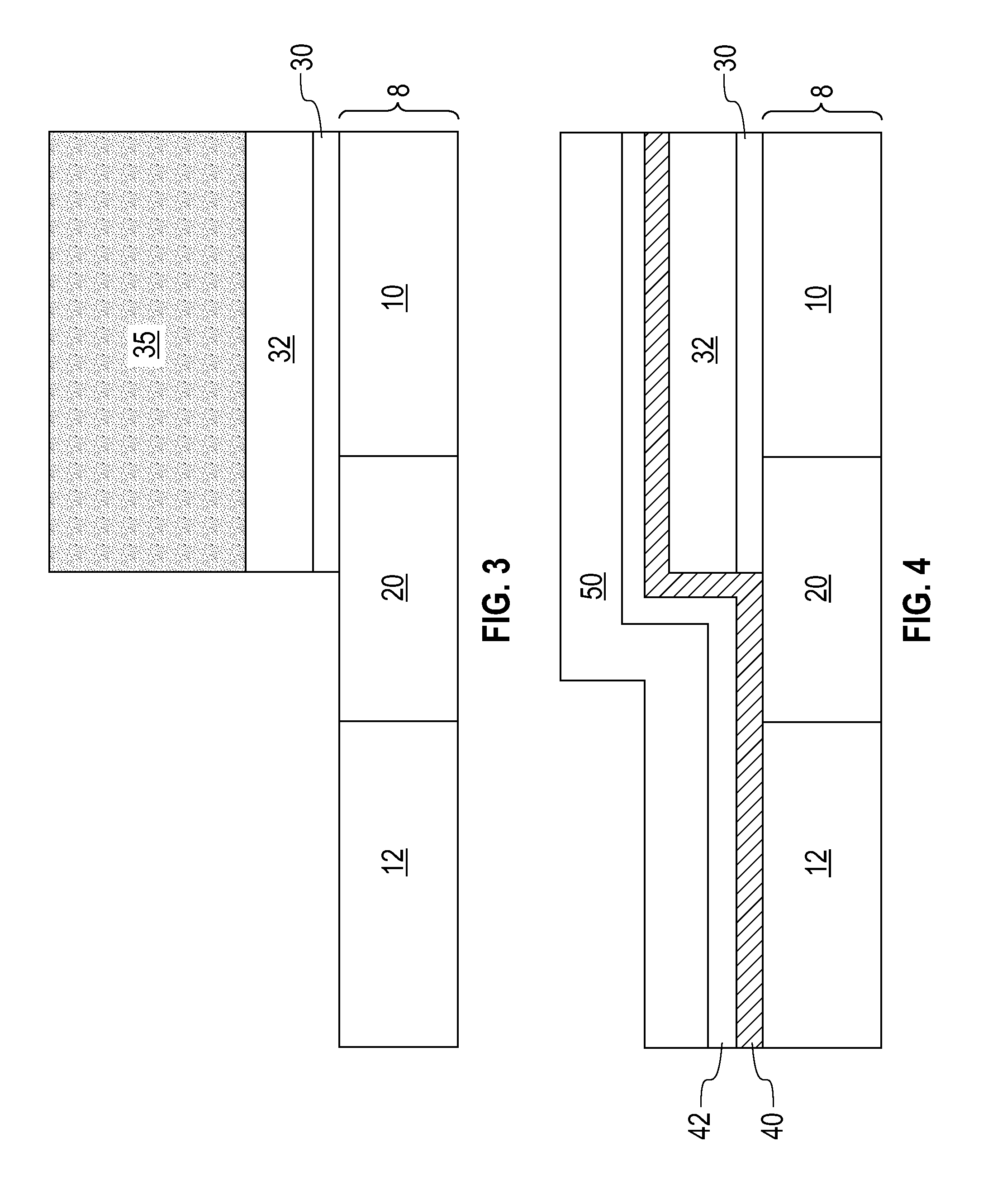

[0054]As stated above, the present invention relates to methods of manufacturing a semiconductor structures with at least one polysilicon gate electrode and at least one high-K dielectric metal gate electrode, which will now be described in greater detail by referring to the drawings that accompany the present application.

[0055]According to FIGS. 1-6, a series of vertical cross-sectional views demonstrating formation of an exemplary semiconductor structure with a polysilicon gate electrode, a high-K dielectric metal gate electrode, and shallow trench isolation are sequentially shown. FIGS. 1-6 are common processing steps according to the four embodiments of the present invention to be shown below. The non-limiting four embodiments of the present invention are shown for demonstration of the practicability of the present invention and obvious alterations and variations of these methods are implied in the present disclosure. Manufacture of more than two gate electrodes according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com