Belt retractor

a belt retractor and belt technology, applied in the field of belt retractors, can solve the problems of low price and small use of clip springs, and achieve the effects of simple production of clip springs, simple transportation of clip springs, and easy simulation of clip springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

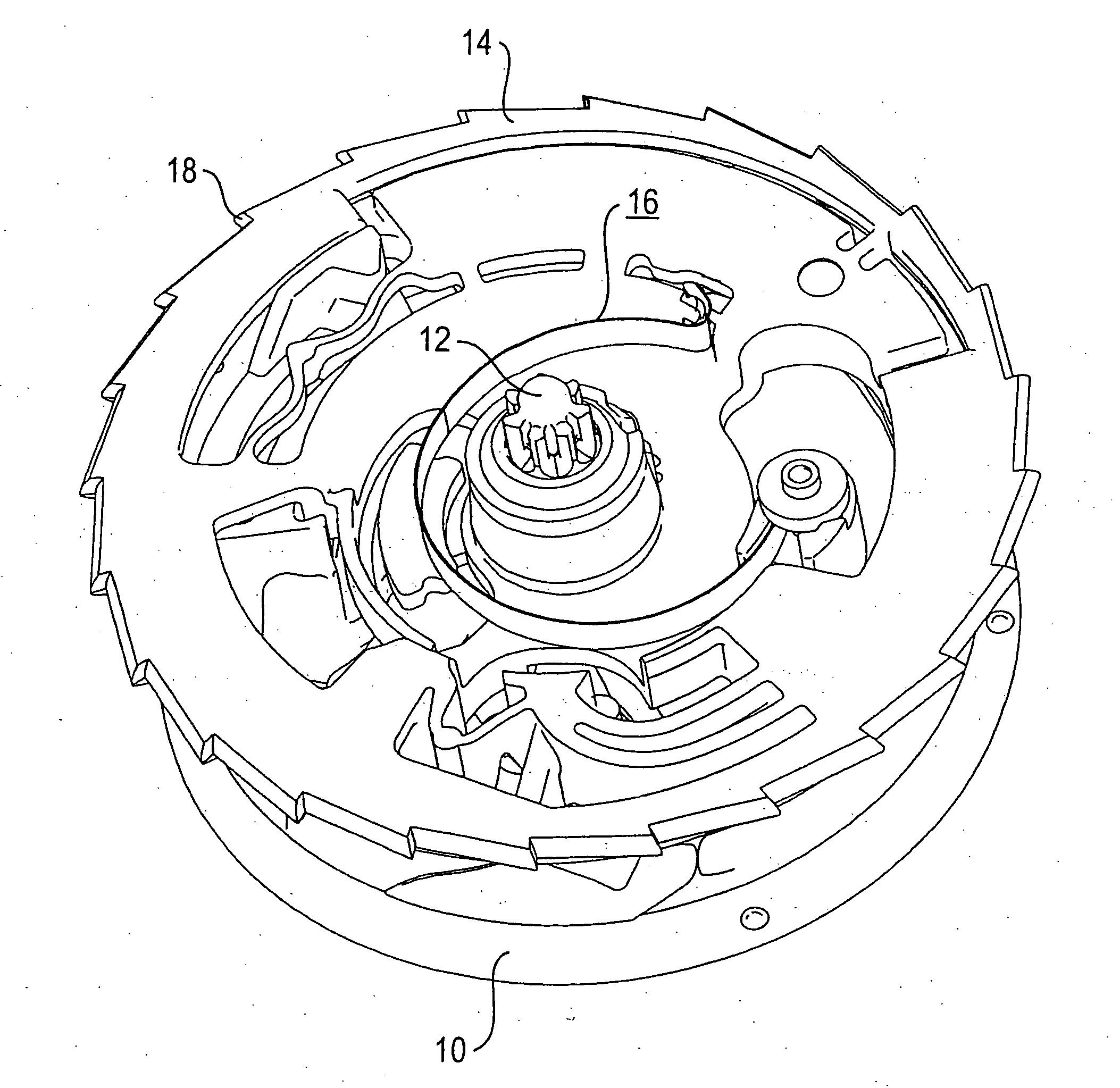

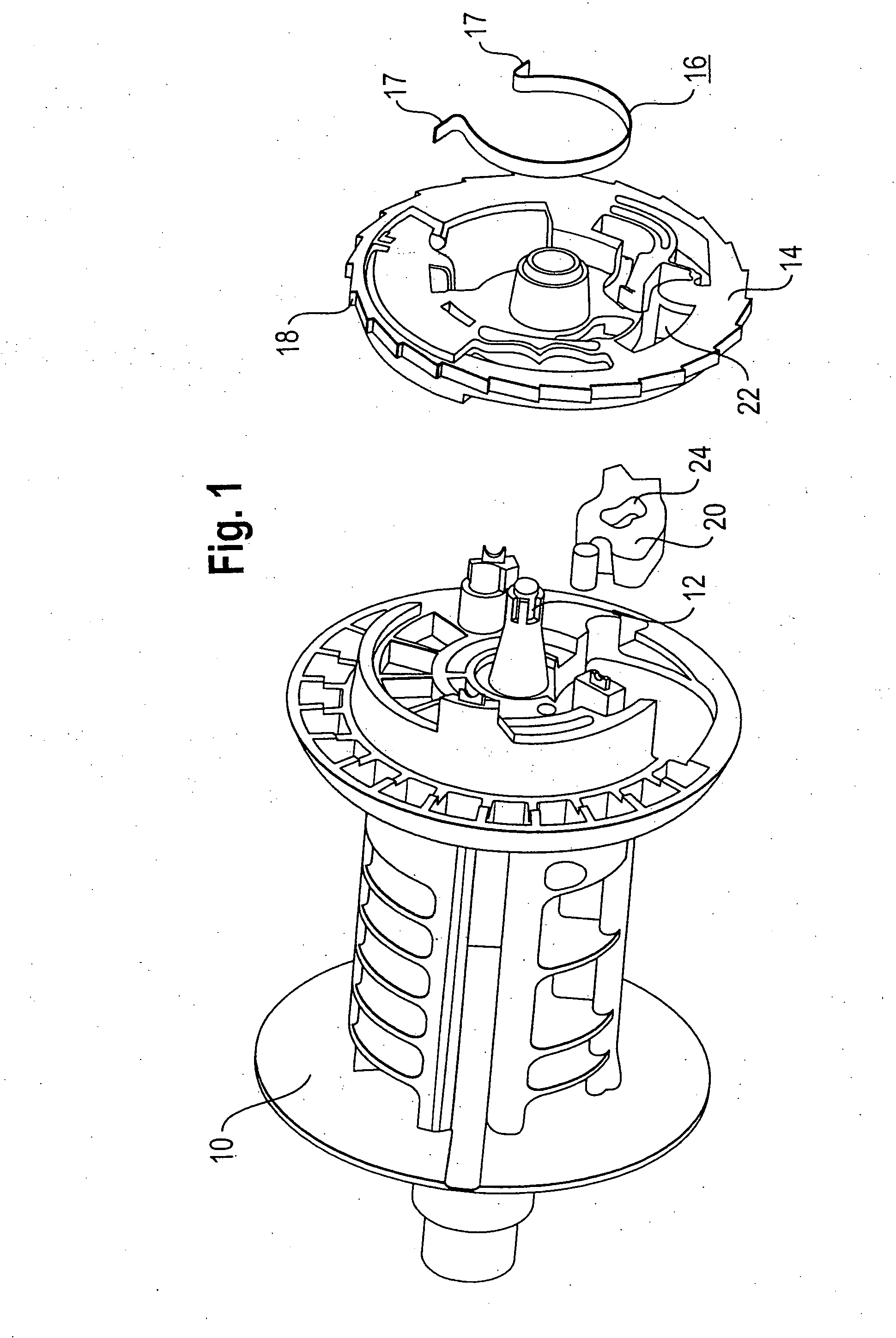

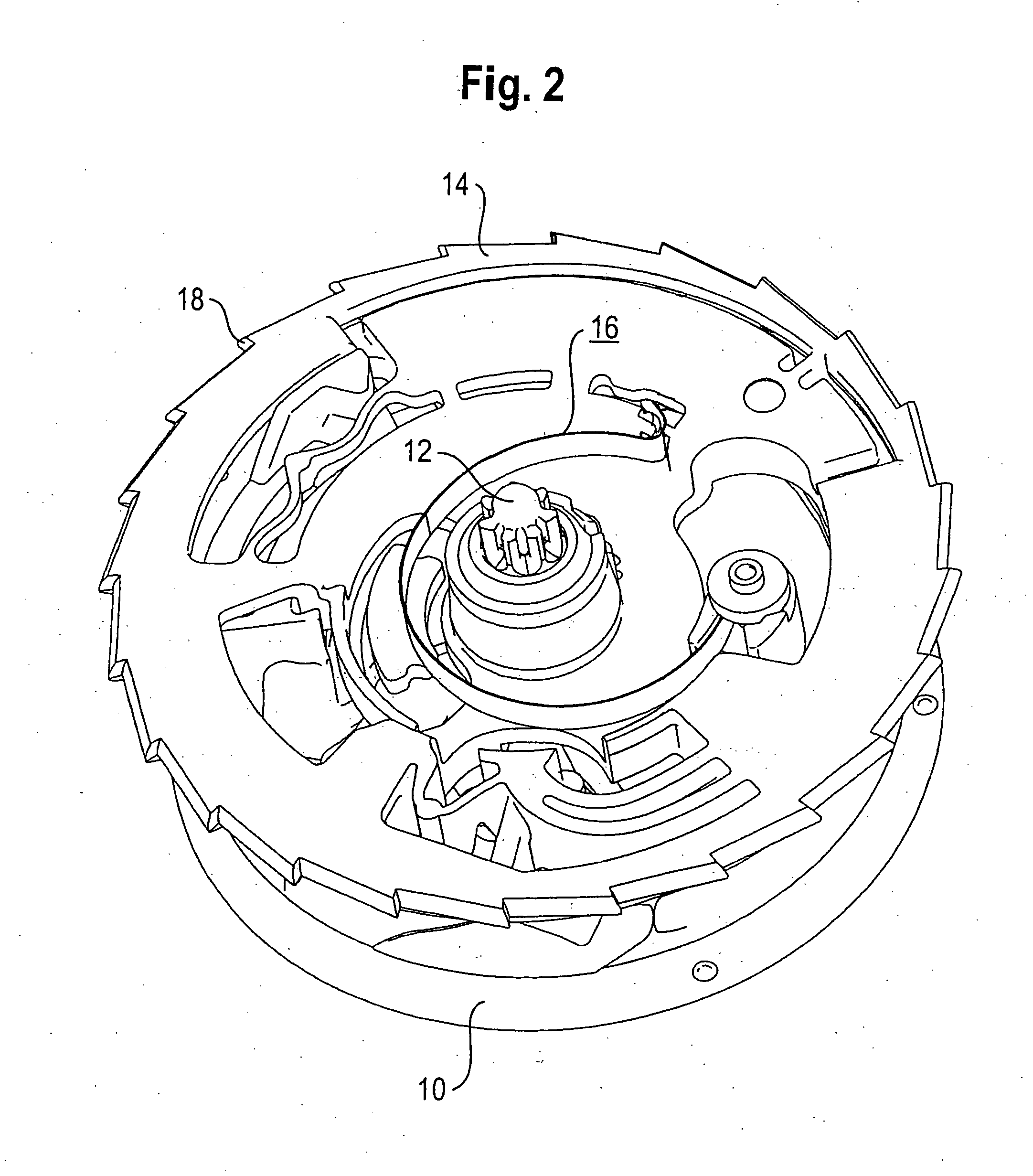

[0013]There is provided a coupling disk 14 which is coaxially connected to the belt reel 10. The basic position of the coupling disk 14 with respect to the belt reel 10 is determined by a clip spring 16, the first end of the clip spring 16 being attached to the coupling disk 14 and its second end being attached to the belt reel 10 (FIGS. 2 and 3), in particular, in such a manner that the clip spring 16 does not engage the reel axle 12 and such that it is tensioned. The clip spring 16 is directly attached to the coupling disc 14. For the attachment to the coupling disk 14 and to the belt reel 10, the ends of the clip spring 16 are bent in the shape of hooks (the hooks 17). The clip spring 16 is eccentrically attached to the belt reel 10 and to the coupling disk 14 (with respect to the reel axle 12) and rotatably supported on the coupling disk 14.

[0014]On its outer periphery the coupling disk 14 is provided with a toothing 18 which may cooperate with a vehicle-sensitive sensor element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com