Integrated Explosion Protection Apparatus For Supervision And Control Of Advanced Electrical Apparatuses

an explosion protection and integrated technology, applied in the direction of manipulators, lighting and heating apparatuses, heating types, etc., can solve the problems of insufficient reliability, inability to optimally locate the system, and high cost, and achieve the effect of cost-effective and reliable application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

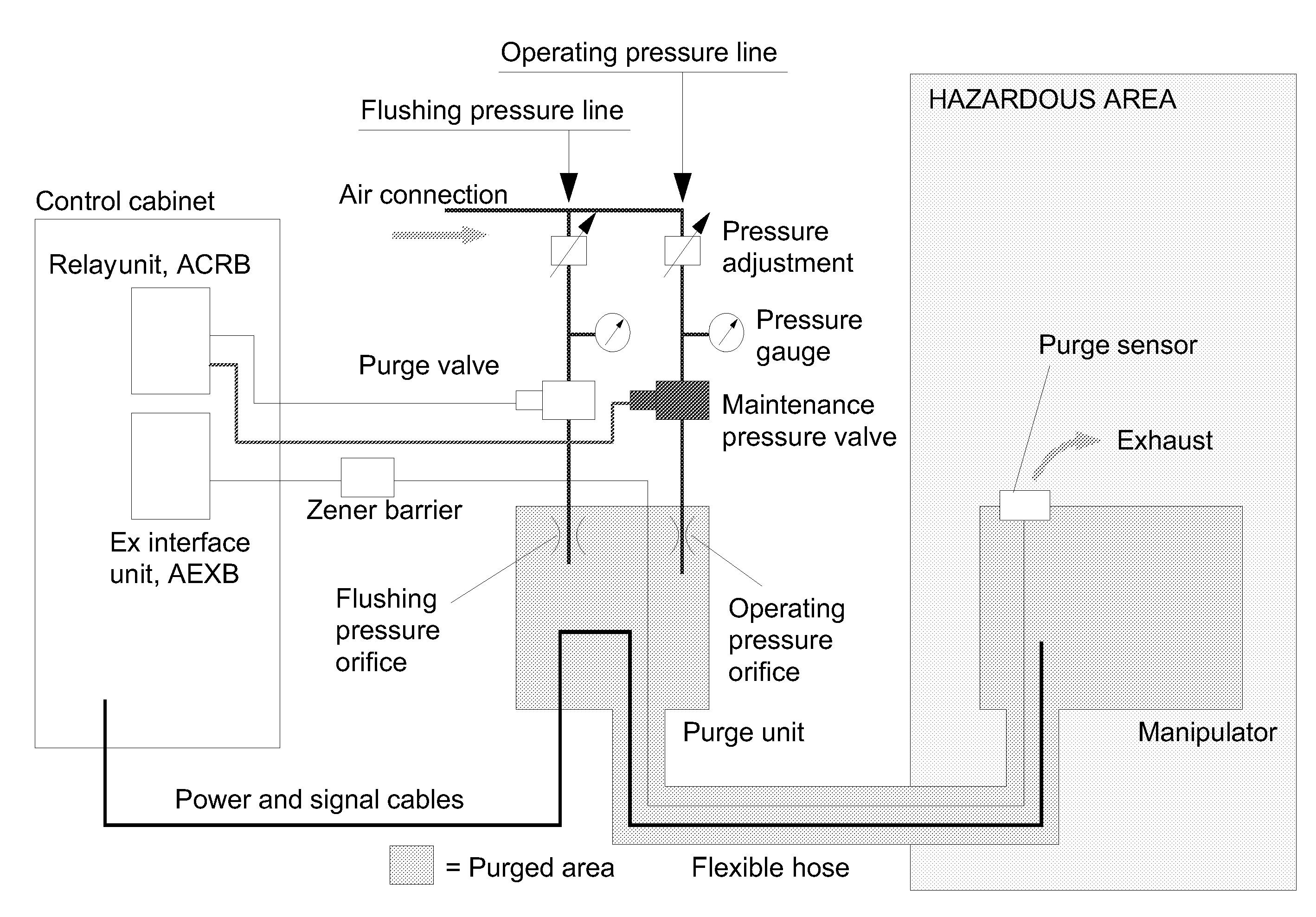

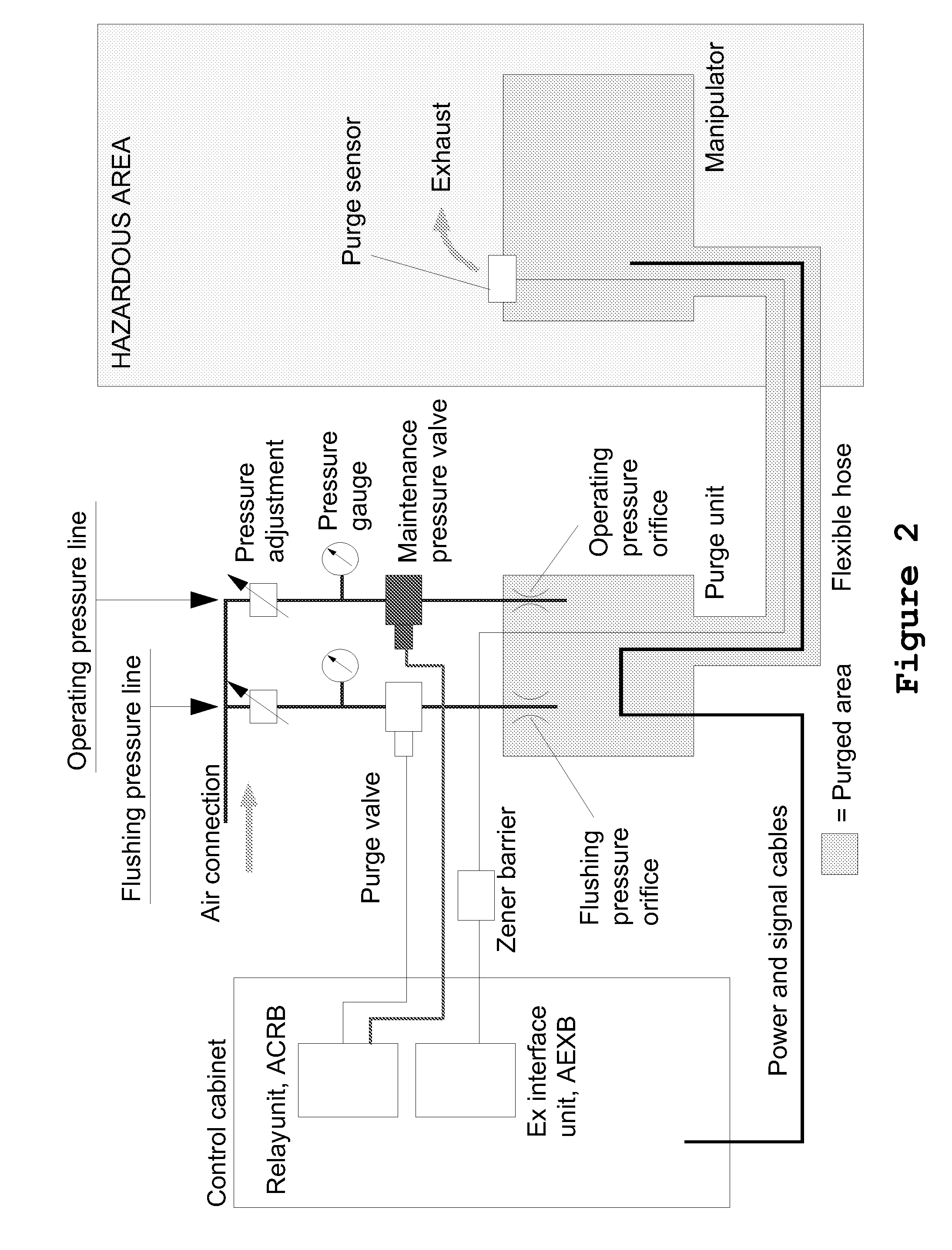

[0033]FIG. 1 illustrates schematically a known example of a pressurized enclosure consisting of serial coupled sub compartments with communicating passages. An inflow of pressurized air is shown schematically to the left and an outflow of the air to the right.

[0034]FIG. 2 illustrates a system overview of the integrated purge and pressure control system that includes a purge and pressure sensor and relief valve unit. A control cabinet is arranged to control a purge valve and a maintenance pressure valve. In a hazardous area a manipulator (not shown) is located inside an enclosure. A purge sensor and an exhaust valve are arranged on the enclosure, that typically is divided in sub compartments. The purge sensor is electrically connected via a cable located in a flexible hose and via a Zener barrier to the control cabinet.

[0035]FIG. 3 illustrates the purge relief valve unit which is designed to take high airflow capacity during purging and to give a determined air leakage during operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com