System and method for engine lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

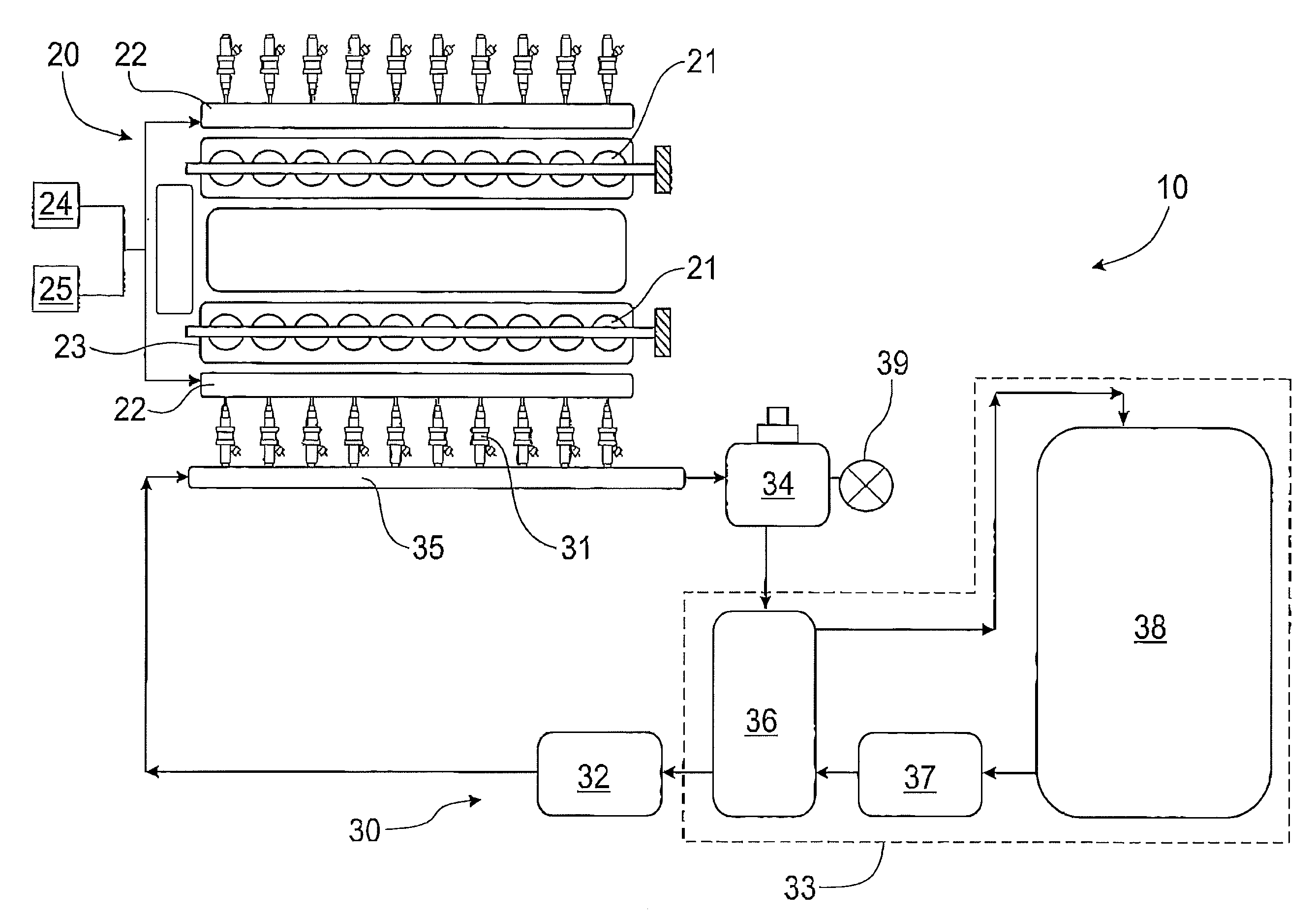

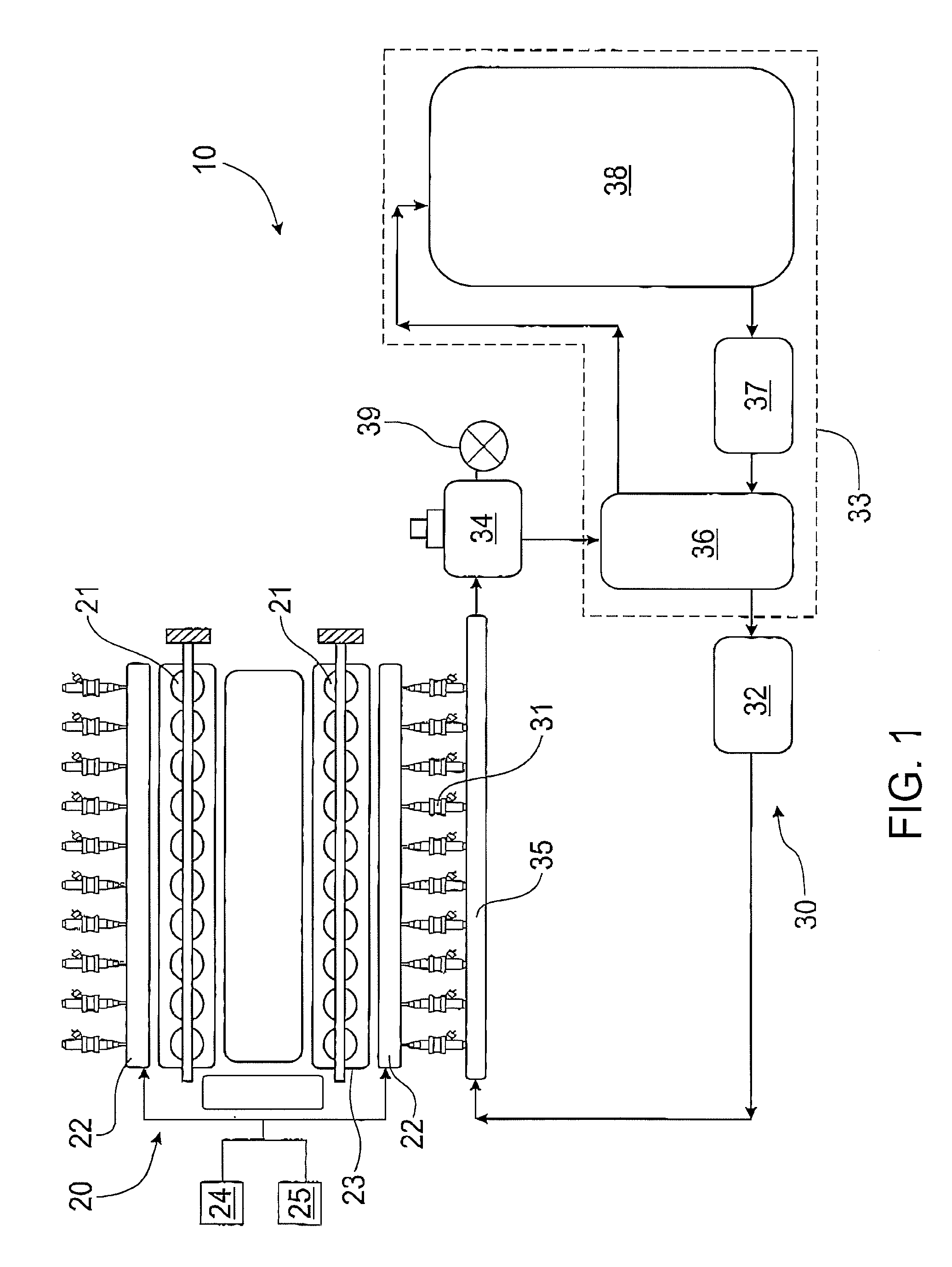

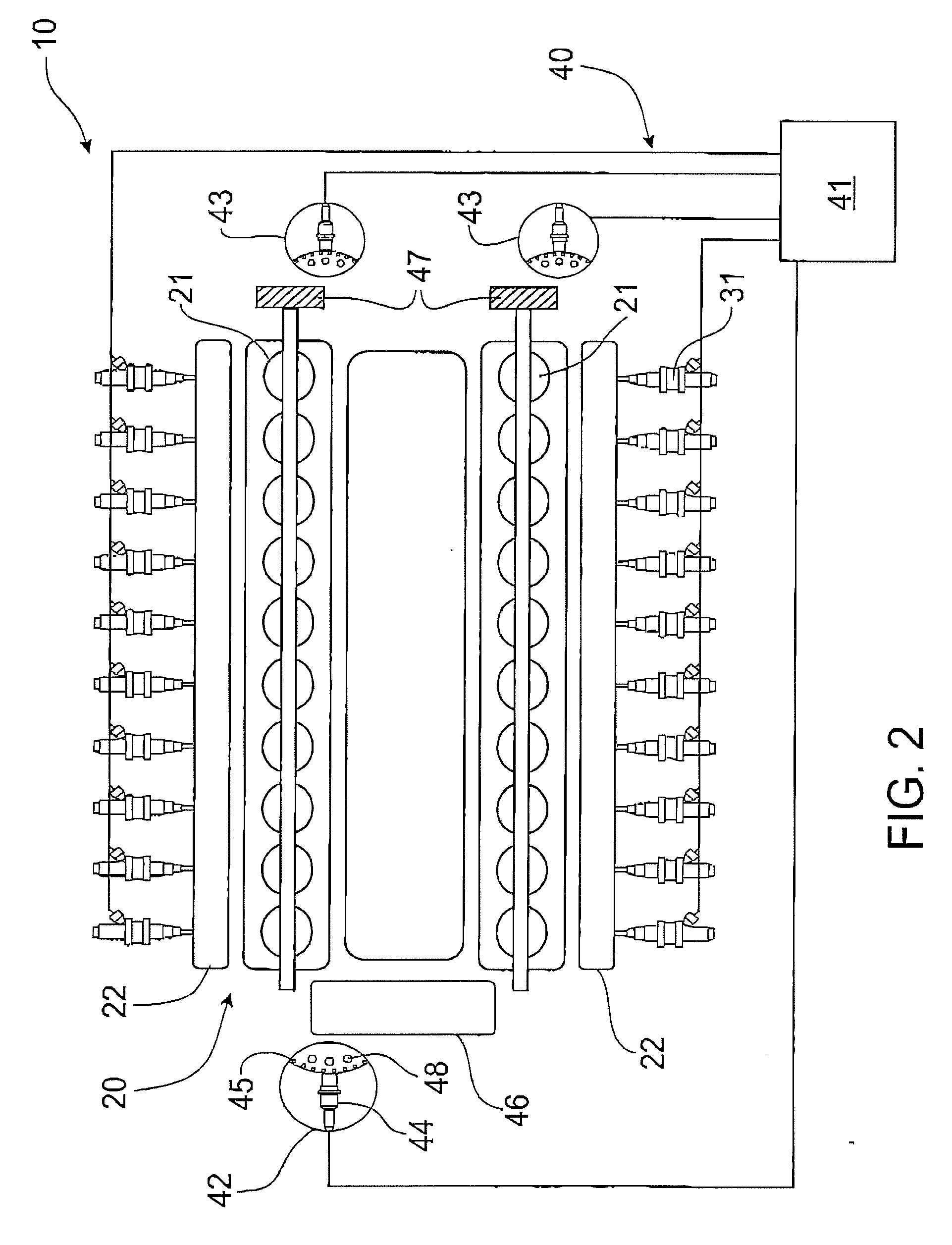

[0030]FIGS. 1 and 2 show a liquid phase lubricant system 10 retrofitted to an existing stationary 20-cylinder diesel V-engine 20 that has been converted to using methane gas.

[0031]The engine 20 includes two rows of cylinders 21. Each cylinder 21 is operatively connected to an intake manifold 22. An air intake system 23 and a gaseous phase fuel delivery system 24 is operatively connected to each cylinder 21 via the intake manifold 22, as known in the prior art.

[0032]The liquid phase lubricant system 10 includes a lubricant delivery system 30 and a lubricant control system 40. Although the invention is explained with reference to stationary engines, the inventor envisages that the invention is also applicable in other environments such as vehicle engines running on similar ‘dry’ fuels.

[0033]FIG. 1 shows the lubricant delivery system 30 which delivers a 10-weight mineral oil to each cylinder 21 of the engine 20. However, it is to be appreciated that other forms of lubricant may be used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com