Energy and Water Conservation in Cooling of Containers Containing Heated Products

a technology for heating products and containers, applied in indirect heat exchangers, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of non-recoverable heat released to the atmosphere at the cooling tower, the amount of heat that can be recovered, and the entire system shut down, so as to reduce or conserve energy and water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

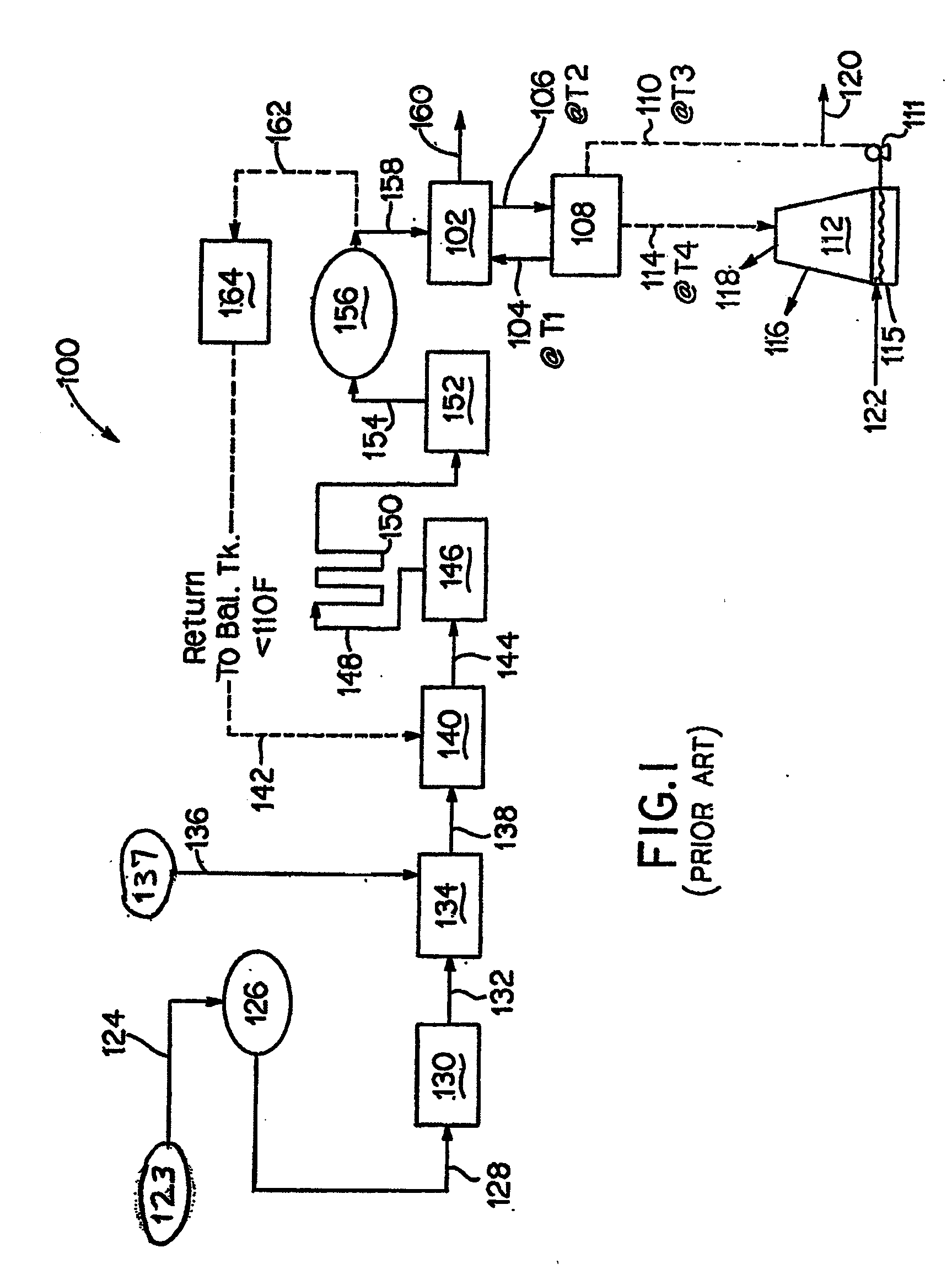

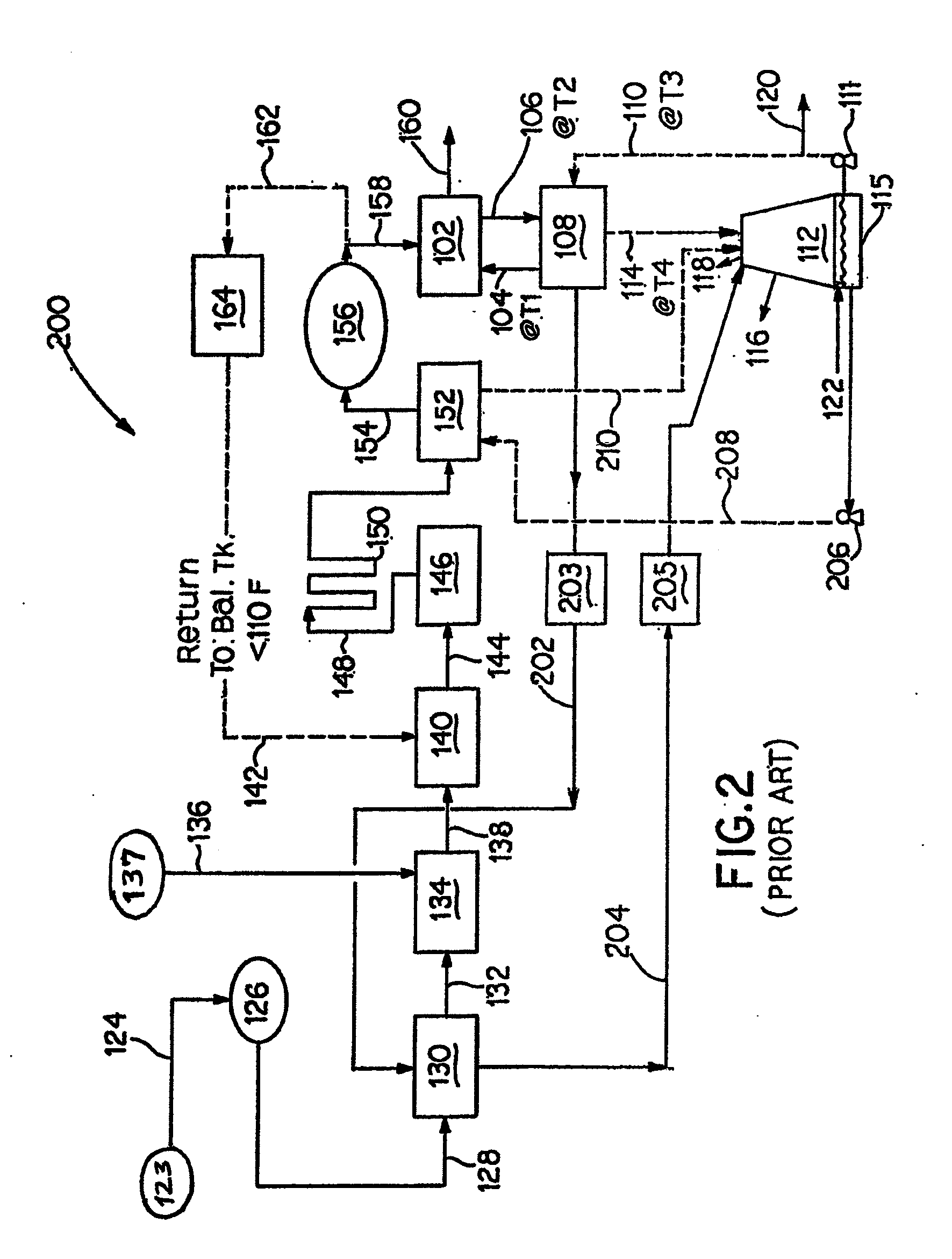

[0034]FIG. 4 depicts the flow rates and temperatures calculated for a nine zone container cooler, with only zones 1, 2, 8, and 9 (zones Z1 through Z9) in a conventional system 100 or 200 as shown in FIG. 1 or 2. Stream 158 comprising bottles 105 containing a beverage having a temperature of 185° F. is shown entering container cooler 102, and exiting container cooler 102 as stream 160 comprising bottles 105 containing the beverage having a temperature of 97.5° F.

[0035]Table 1 depicts calculated parameters with respect to a counter current container cooler or bottle cooler 102, when a conventional system as illustrated in FIG. 1 or FIG. 2 is used. In this example, counter current bottle cooler 102 has nine (9) zones numbered Z1 through Z9. At zone 1, the heated and bottled beverages enter the counter current bottle container cooler 102, and are moved by a belt through the successive numbered zones, until the bottled beverages exit zone 9. At zone 9, the first water stream 104 depicted...

example 2

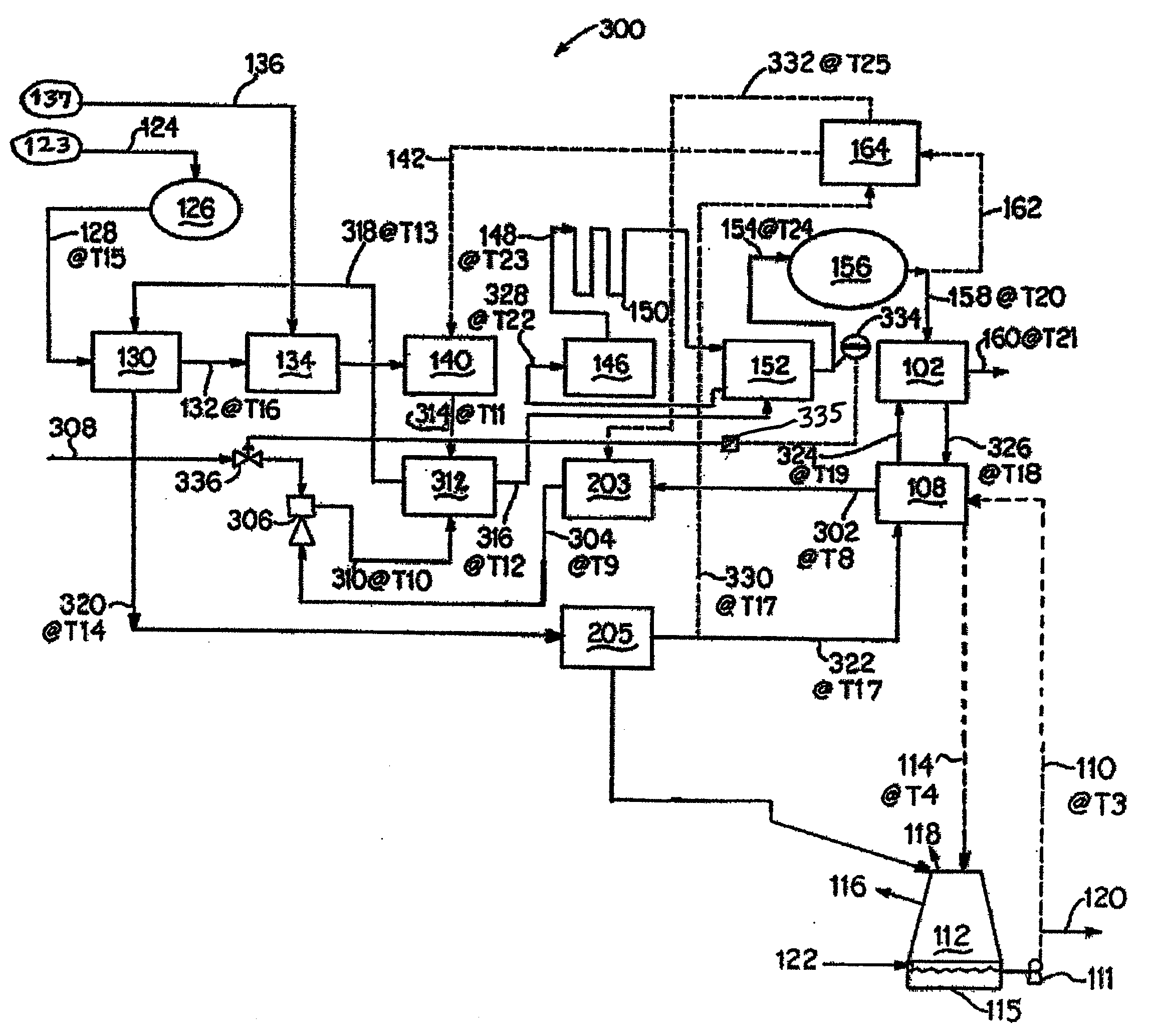

[0037]FIG. 5 depicts the flow rates and temperatures calculated for a nine zone container cooler, with only zones 1, 2, 8, and 9 (zones Z1 through Z9) depicted in a system 300 as shown in FIG. 3A.

[0038]Table 2 depicts calculated parameters with respect to a counter current container cooler or bottle cooler 102, when a system 300 is used as illustrated in FIG. 3A. In this example, counter current bottle cooler 102 has nine (9) zones numbered Z1 through Z9. At zone 1, the heated and bottled beverages enter the counter current bottle container cooler 102, and are moved by a belt through the successive numbered zones, until the bottled beverages exit zone 9. At zone 9, the stream 324 depicted in FIG. 3A enters current bottle container cooler 102, where it is sprayed over bottled beverages moving through zone 9, is then collected at the bottom of zone 9 and then routed to zone 8 where sprayed over bottled beverages moving through zone 8, etc., until the water stream exits bottle cooler 1...

embodiment 1

[0047]A system or apparatus comprising a chamber where a product stream is formed, a pre-heater located downstream of the chamber and upstream of a heater that heats the product stream to a desired temperature, the pre-heater comprising a circulating stream of a first heat transfer stream that pre-heats the food product, a container cooler comprising a circulating stream of a second heat transfer stream that cools containers containing the heated product coming out of the heater, and a heat exchanger where heat from the second heat transfer stream is transferred to the first heat transfer stream. The chamber can be any suitable structure wherein a product can be formed, including but not limited to a tank, a vessel, a nozzle, and / or a pipe. The product can be a food product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com