Thermoelectric conversion module and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

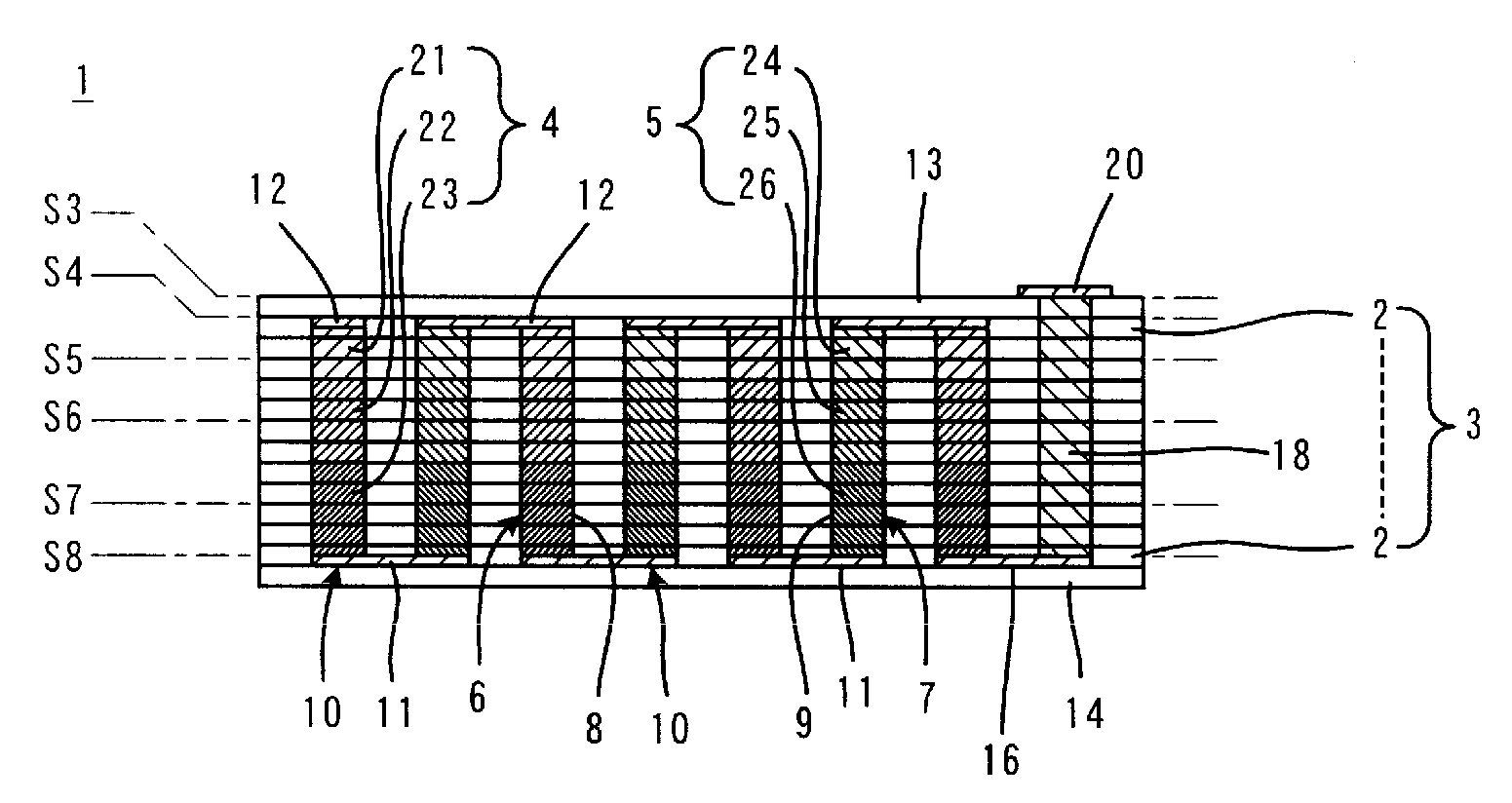

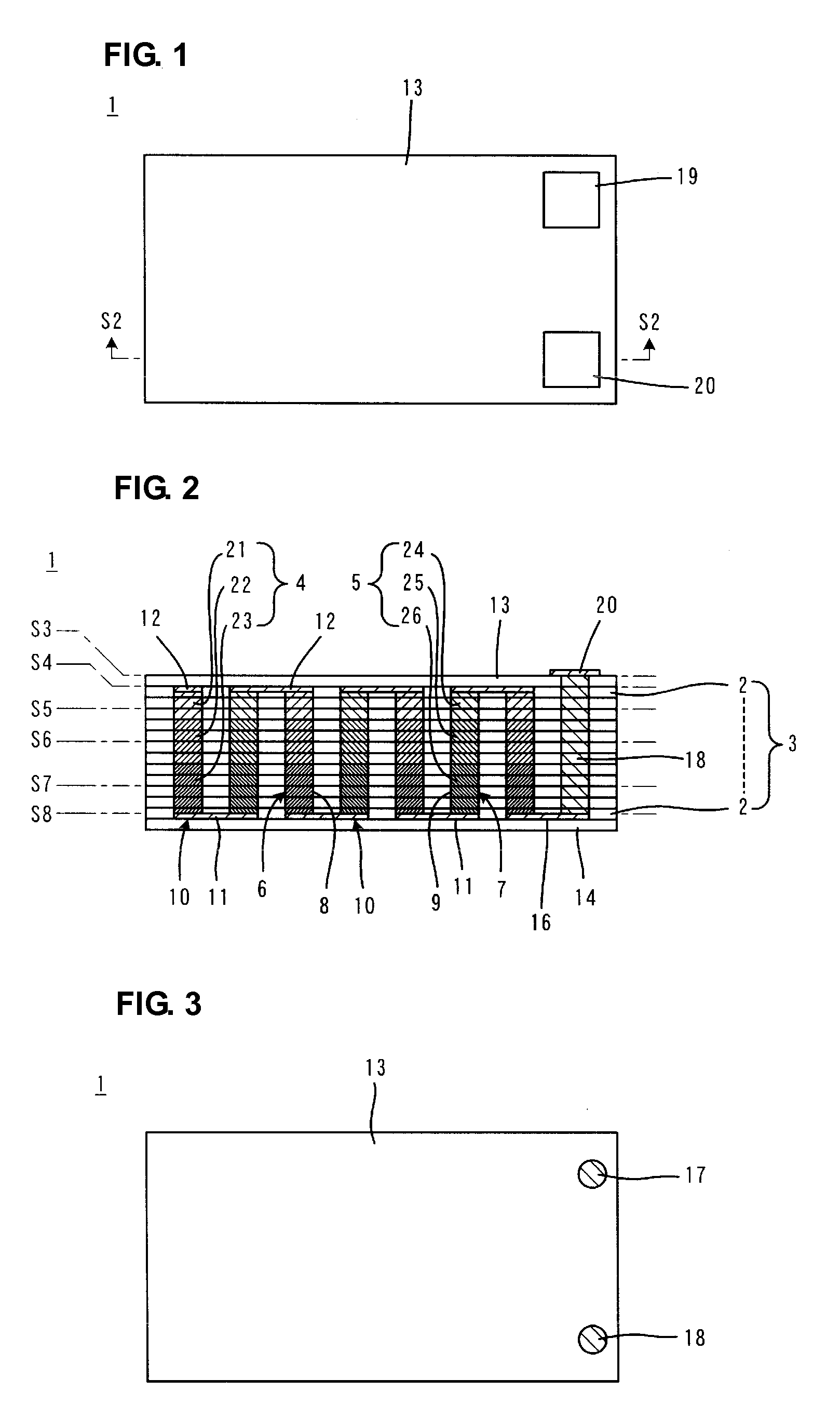

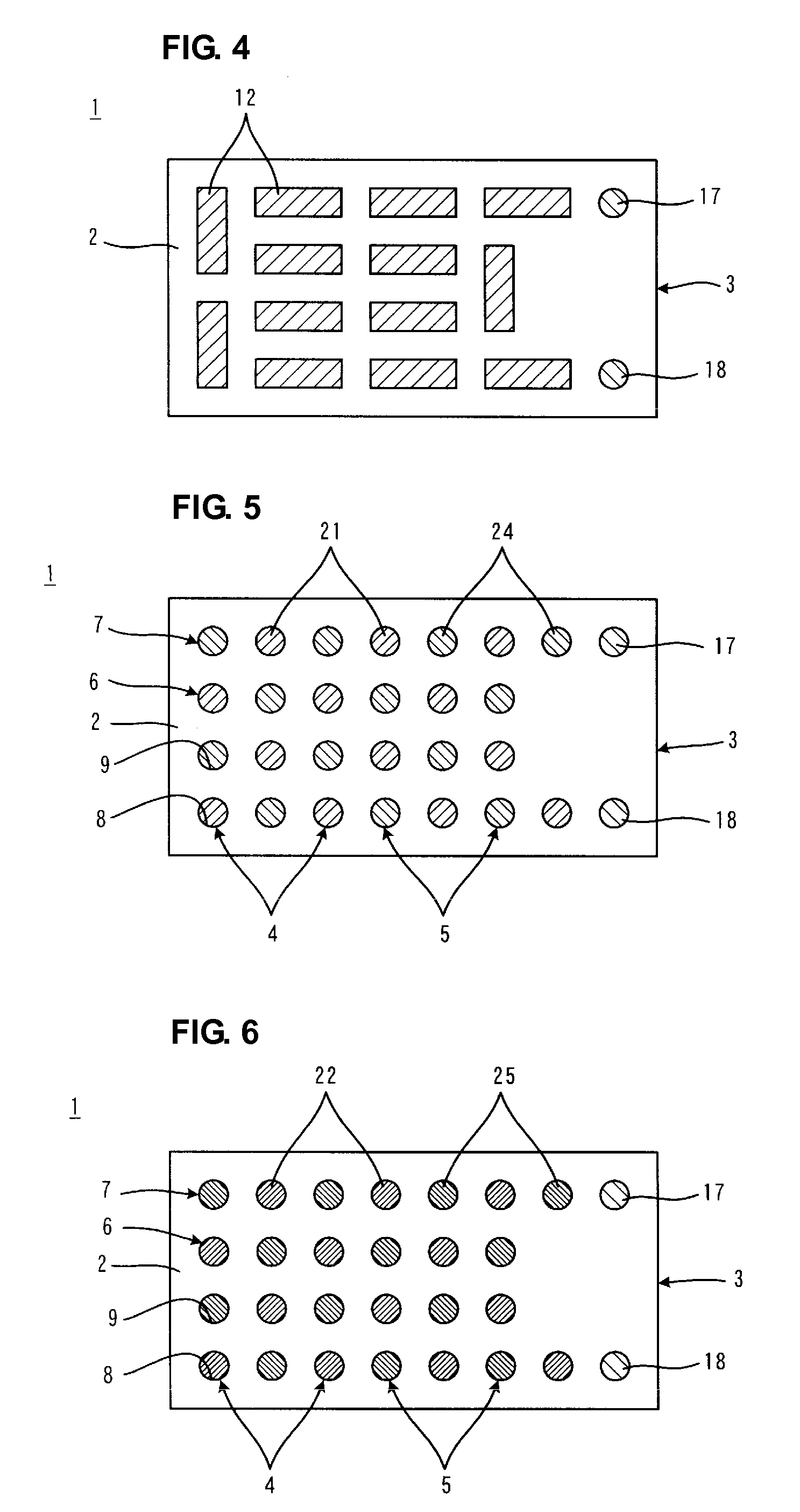

[0052]FIGS. 1 to 8 illustrate a thermoelectric conversion module 1 according to a first preferred embodiment of the present invention. FIG. 1 is a plan view of the thermoelectric conversion module 1. FIG. 2 is a sectional view taken along the line S2-S2 of FIG. 1. FIGS. 3 to 8 are sectional plan views taken along the lines S3 to S8, respectively, of FIG. 2.

[0053]The thermoelectric conversion module 1 includes a laminate 3 including a plurality of stacked insulating layers 2 which are electrically insulative. The insulating layers 2 are made of an alumina-based material, such as a BaO—Al2O3—SiO2 ceramic material or a ZnO—MgO—Al2O3—SiO2 glass material, for example. The thermoelectric conversion module 1 further includes a plurality of p-type thermoelectric semiconductors 4 and n-type thermoelectric semiconductors 5 arranged in the laminate 3. The p-type thermoelectric semiconductors 4 are made of, for example, Chromel. The n-type thermoelectric semiconductors 5 are made of, for exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com