Chemical mechanical polishing apparatus and chemical mechanical polishing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

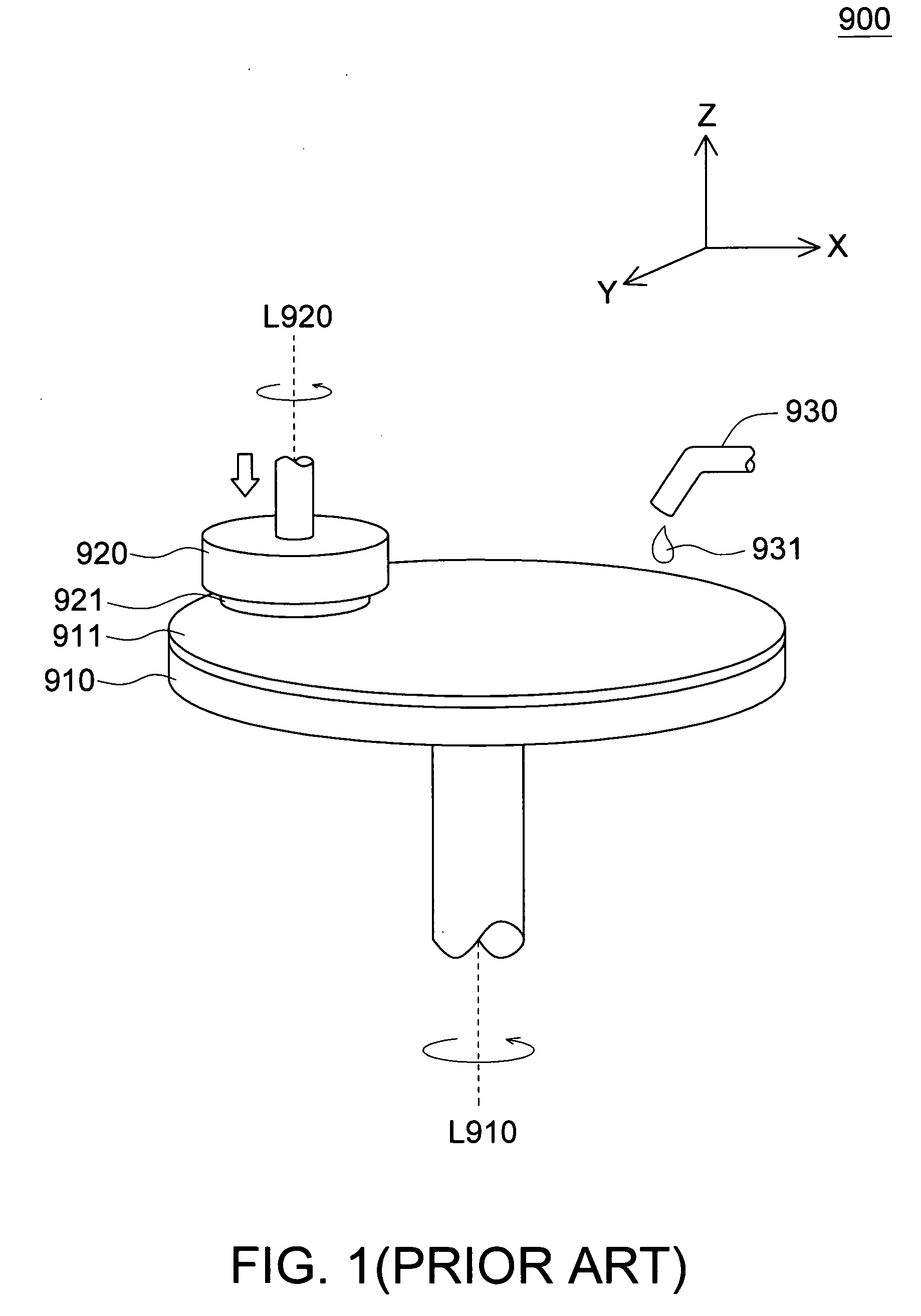

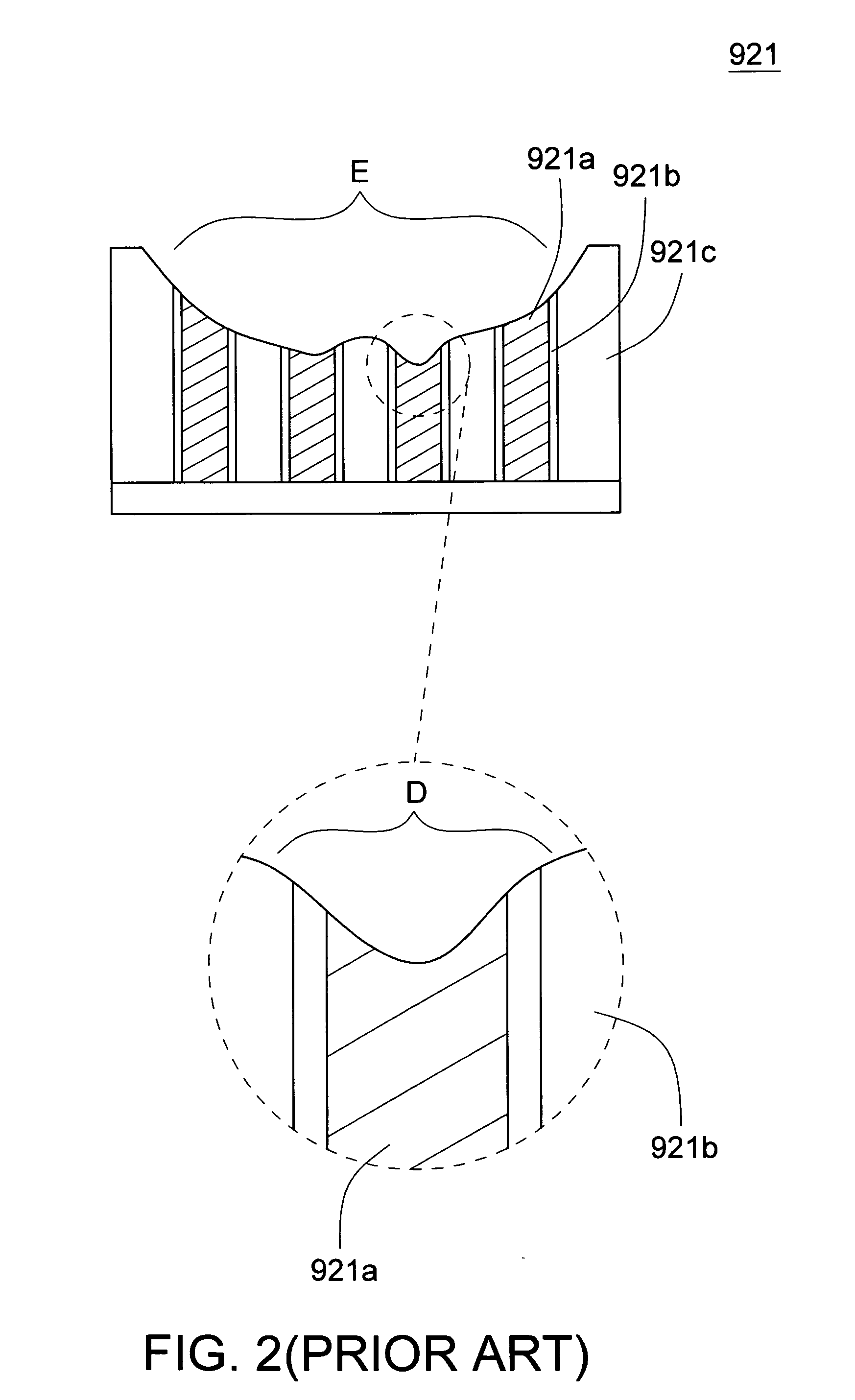

[0035]Referring to FIG. 3, a perspective of a chemical mechanical polishing apparatus 100 according to a first embodiment of the invention is shown. The chemical mechanical polishing apparatus 100 includes a carrier 110, a polishing platen 120, a polishing slurry injector 130 and a controlling unit 140. The carrier 110 used for carrying a wafer 111 drives the wafer 111 to revolve around a first central axis L110. The polishing platen 120 is used for pasting a polishing pad 121 thereon. In the present embodiment of the invention, the polishing platen 120 is located underneath the carrier 110 and is larger than the carrier 110. A positive pressure F is applied between the carrier 110 and the polishing platen 120 for enabling the polishing pad 121 and the wafer 111 to contact each other tightly. The polishing platen 120 drives the polishing pad 121 to revolve around a second central axis L120. Generally speaking, the polishing pad 121 and the carrier 110 are rotated in opposite directi...

second embodiment

[0052]Referring to FIG. 7, a perspective of a chemical mechanical polishing apparatus 200 according to a second embodiment of the invention is shown. The chemical mechanical polishing apparatus 200 of the present embodiment of the invention differs with the chemical mechanical polishing apparatus 100 of the first embodiment in that the chemical mechanical polishing apparatus 200 further includes a flatness sensor 250 and at least a supplementary polishing platen 260. The supplementary polishing platen 260 is used for pasting a supplementary polishing pad 261 thereon. In the present embodiment of the invention, the carrier 210 and the wafer 211 are disposed at the bottom while the polishing platen 220, the polishing pad 221, the supplementary polishing platen 260 and the supplementary polishing pad 261 are disposed at the top. As for other similarities, the same designations are used and are not repeated here.

[0053]Referring to both FIG. 7 and FIG. 8. FIG. 8 is a flowchart of a chemi...

third embodiment

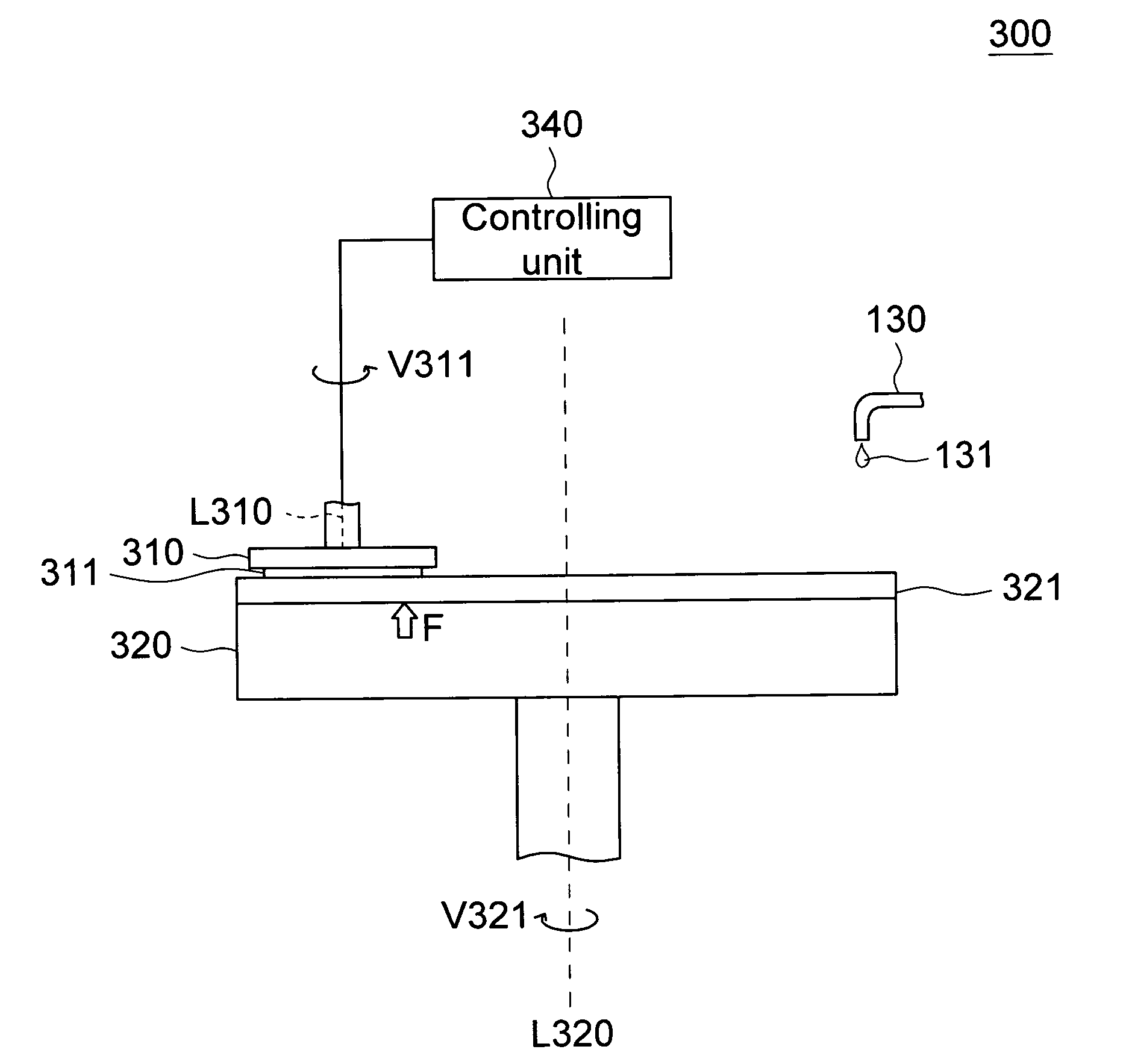

[0054]Referring to FIG. 9, a perspective of the chemical mechanical polishing apparatus 300 according to a third embodiment of the invention is shown. The carrier 310 drives the wafer 311 to revolve at a first rotation rate V311, and the poishing platen 320 drives the polishing pad 321 to revolve at a second rotation rate V321.

[0055]Referring to FIG. 10A and FIG. 10B. FIG. 10A is a top view of the wafer 311. FIG. 10B is a side view of the wafer 311. As indicated in FIG. 10A, the wafer 311 has N wafer sub-regions Wi′i=1˜N. As indicated in FIG. 10B, each wafer sub-region Wi has a first thickness d1i′i=1˜N. As the surface of the wafer 311 is not even, the first thickness d1i′i=1˜N is not identical.

[0056]Referring to FIGS. 11A-11B, various side views of the wafer 311 and the polishing pad 321 are shown. During the rotation of the wafer 311 and the polishing pad 321, the position at which a wafer sub-region Wi′i=1˜N contacts the polishing pad 321 keeps changing. At a particular time t, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com