Cold forming process for manufacturing ball pivots

a technology of ball pivots and forming processes, which is applied in the direction of manufacturing tools, mechanical equipment, rotary machine parts, etc., can solve the problems of generating cost-intensive and time-consuming operations, reducing the need for manufacturing costs, and requiring the purchase of waste materials as a first semi-finished produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

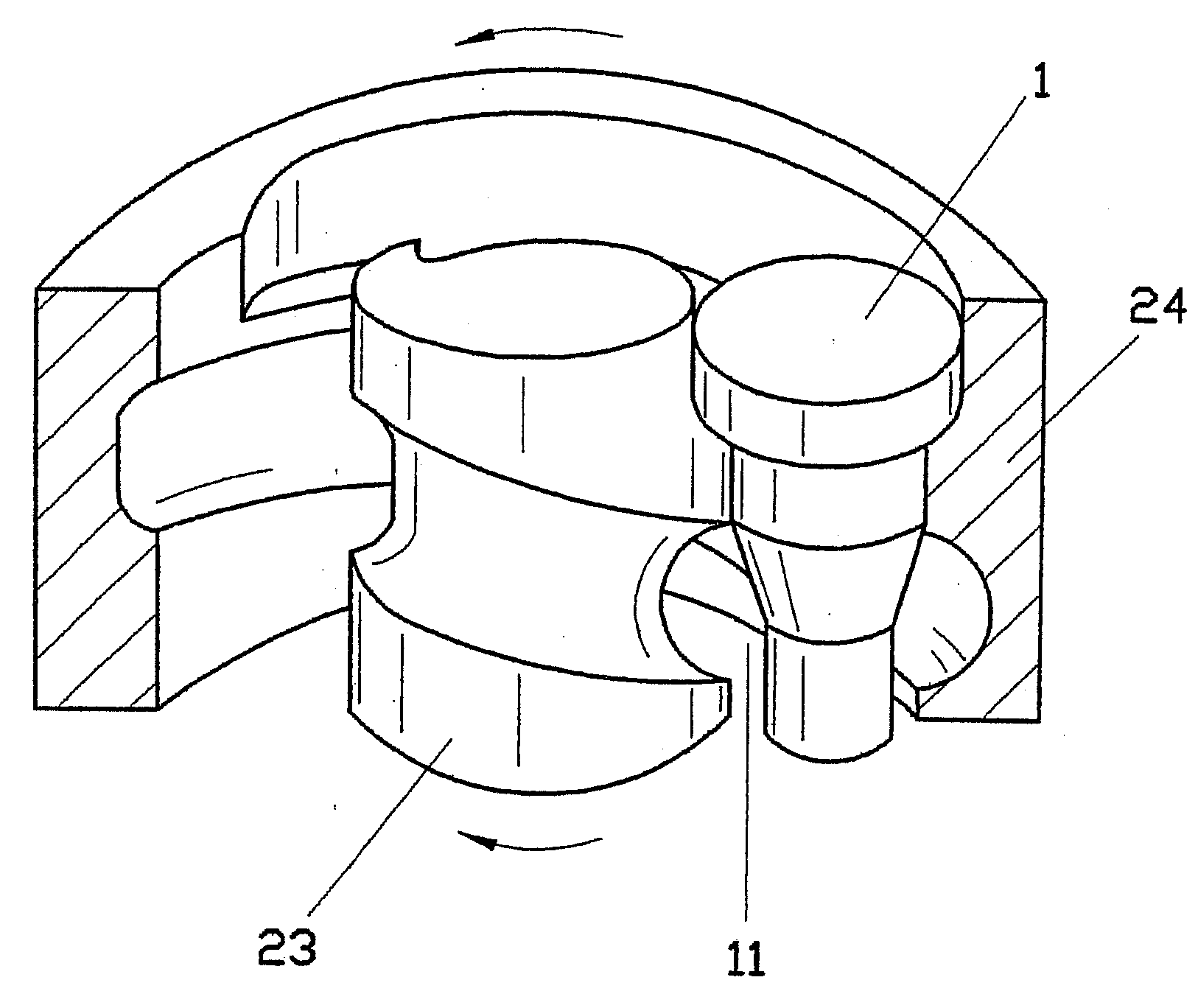

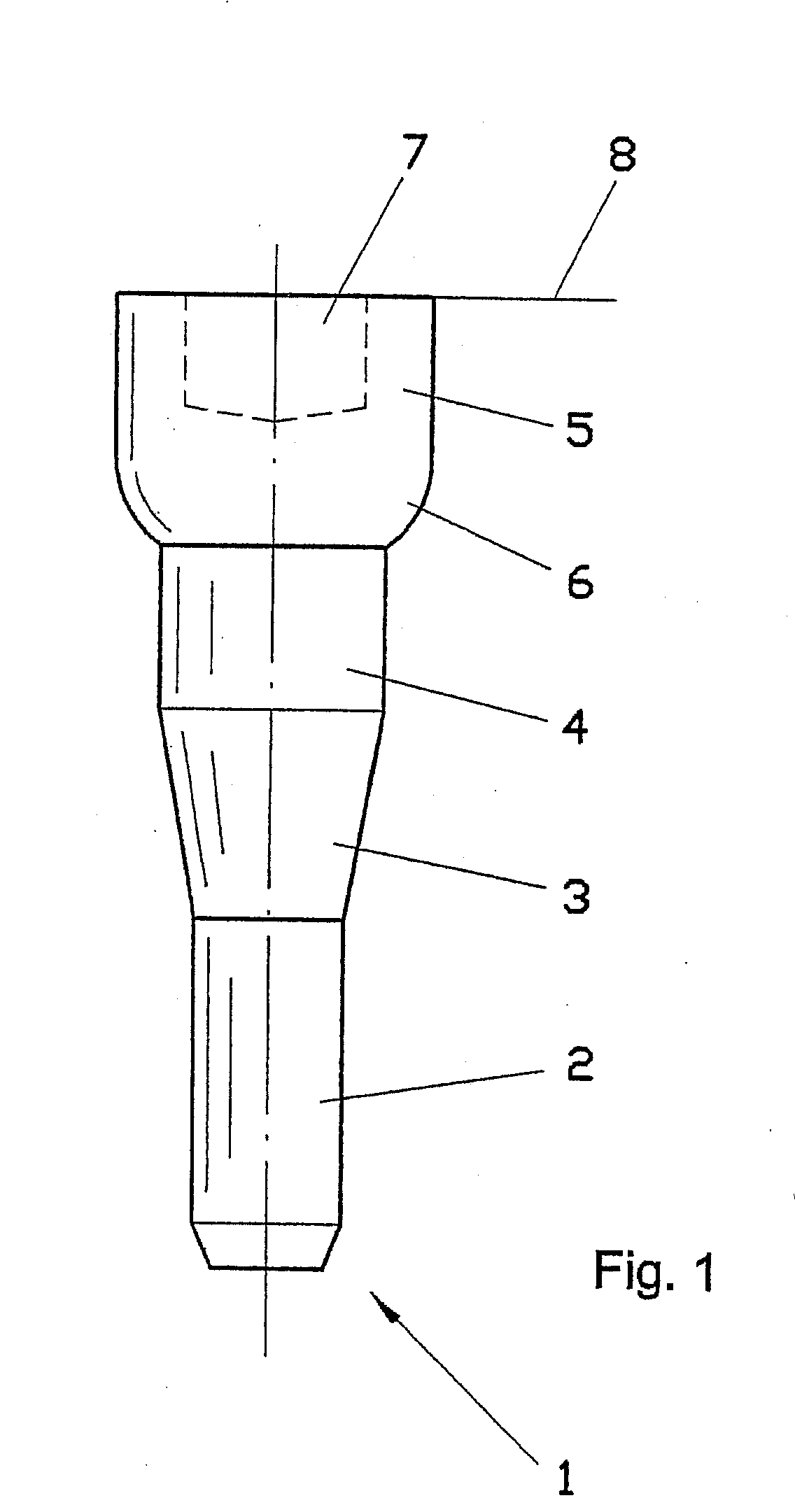

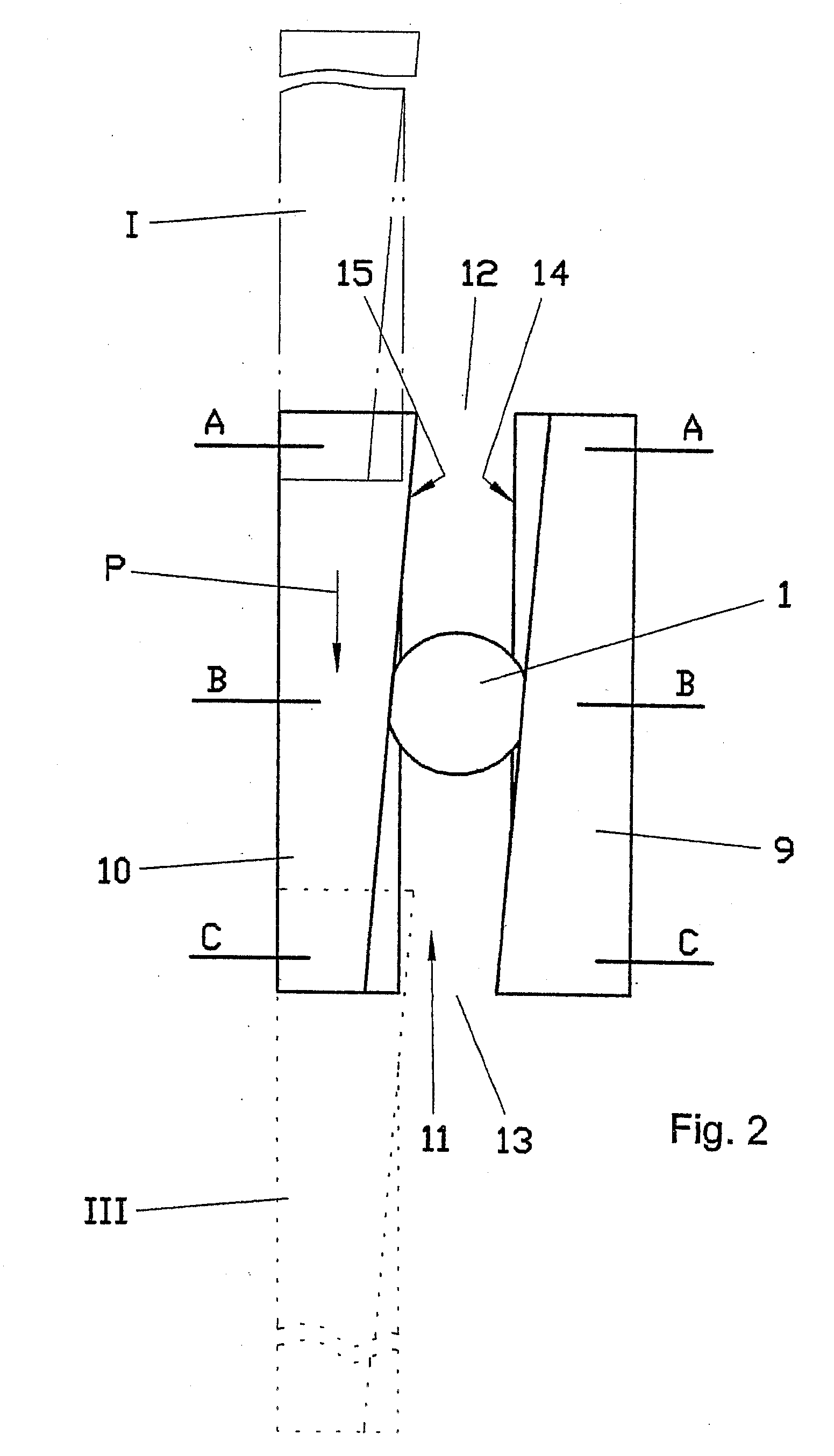

[0026]Referring to the drawings in particular, the ball pivot blank shown in FIG. 1 is manufactured by means of an extrusion process and comprises essentially a plurality of partial areas of different three-dimensional shapes arranged one after another in the longitudinal direction of the ball pivot. After extrusion, the different areas are to be formed into their final shape by means of the combination of process features that are essential for the present invention, and a ball pivot shape corresponding to the view in FIG. 3C is obtained after completion of the cold forming according to the present invention.

[0027]Thus, the ball pivot blank, designated by 1 as a whole, comprises, according to the view in FIG. 1, a cylindrical area 2, which is arranged at a free end of the ball pivot blank 1 and on which a thread for fastening the ball pivot to a machine or body component is located after the completion of the ball pivot. The cylindrical area 2 is joined directly by a cone area 3. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Fatigue strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com