Elastic Composite Film and Composite Fabric and Production Processes Thereof

a composite fabric and elastic technology, applied in the direction of film/foil adhesives, straight-bar knitting machines, synthetic resin layered products, etc., can solve the problems of increasing production costs, poor appearance, and insufficient elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

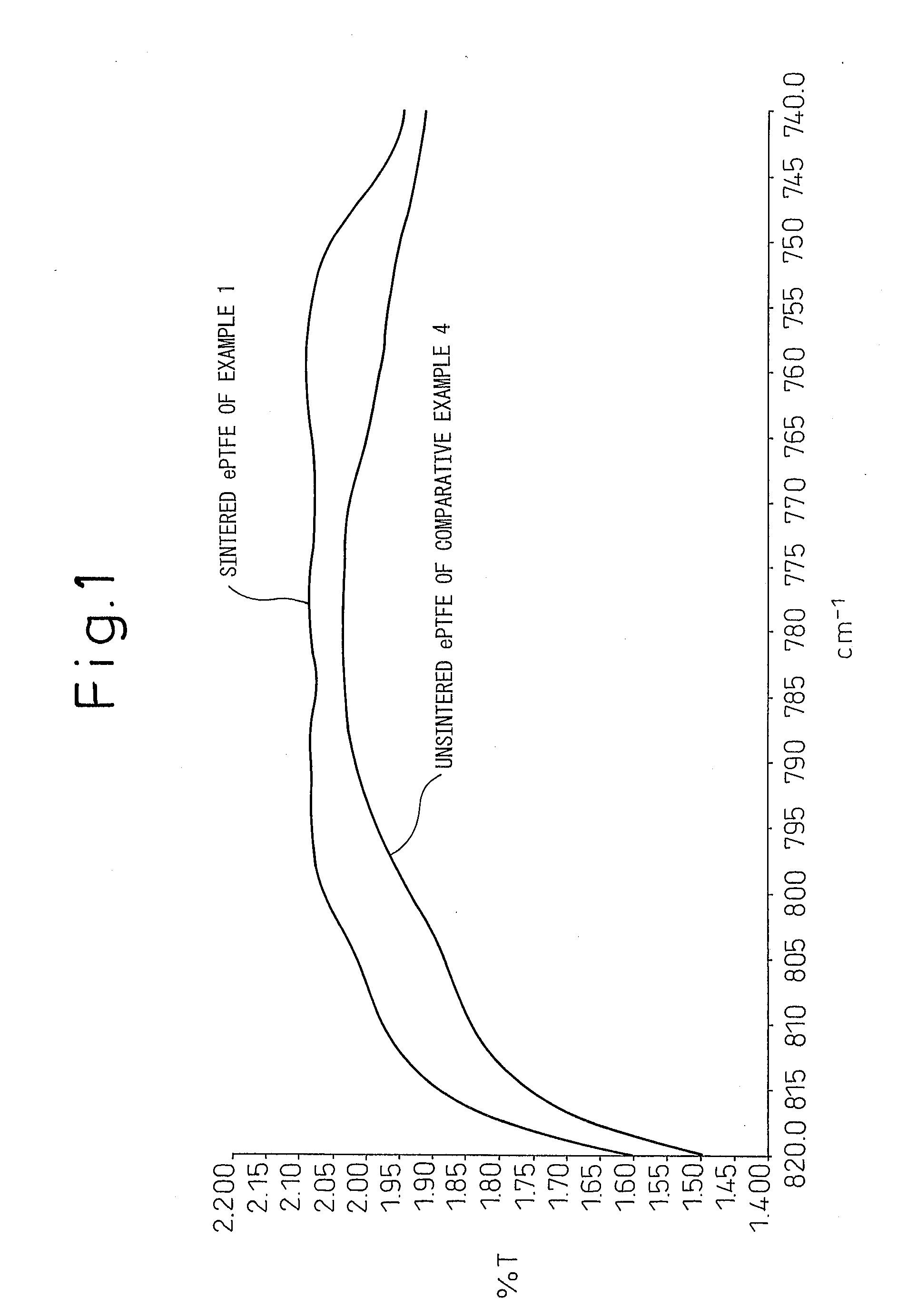

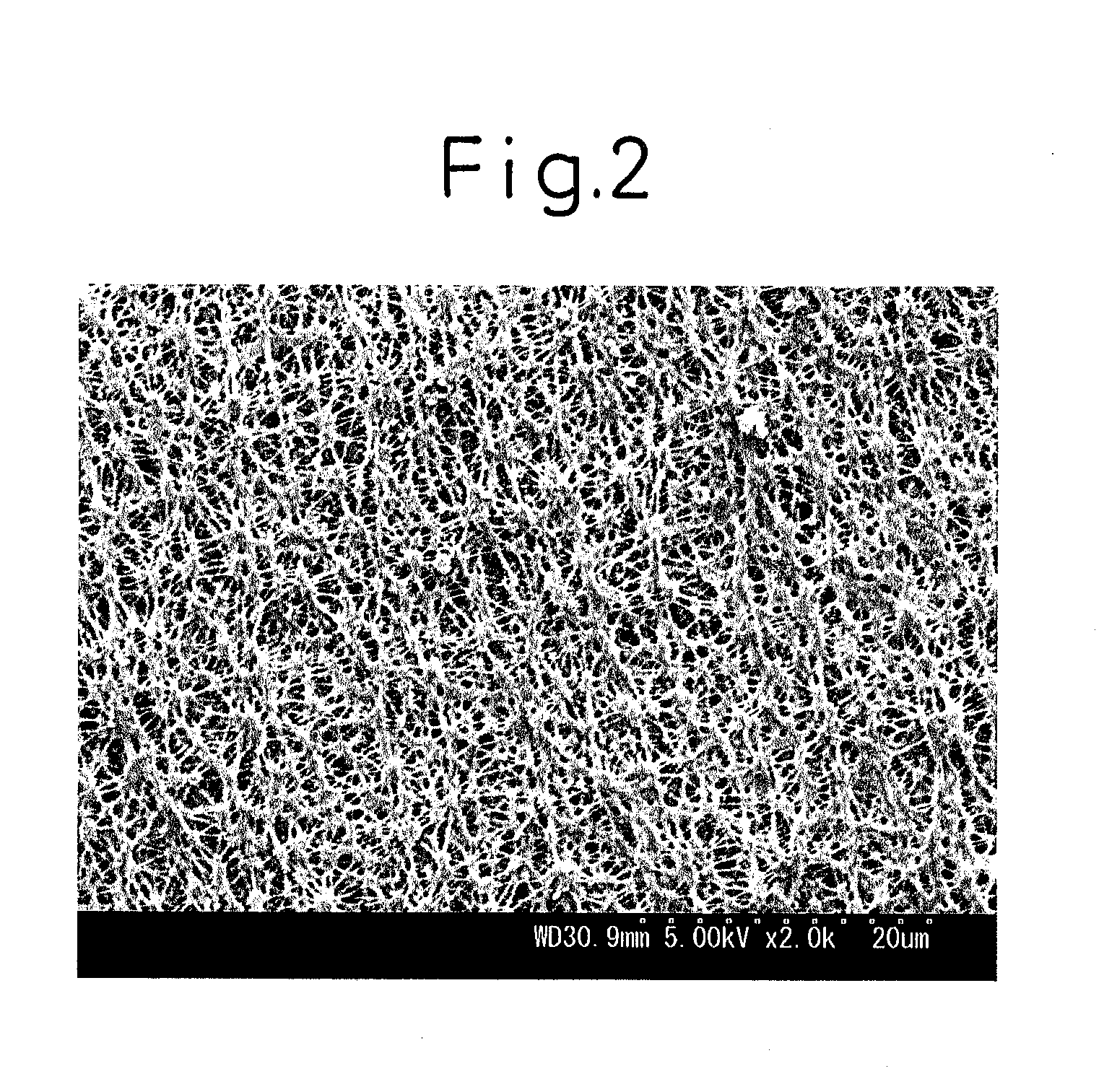

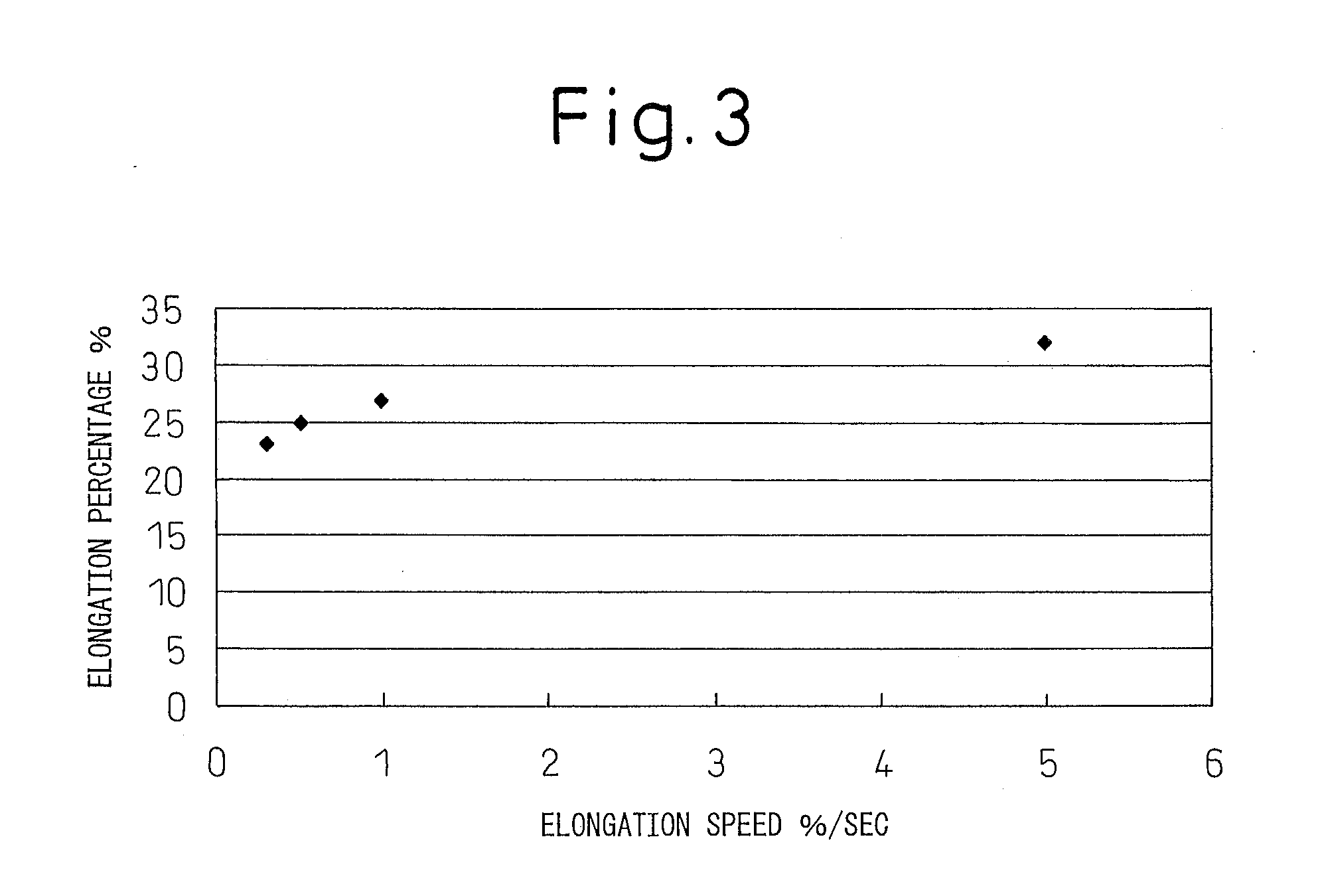

example 1

[0091]Ethylene glycol was added to a hydrophilic polyurethane resin (Dow Chemical Co., trade name: Hipore 2000) at a ratio in which the equivalent weight ratio of NCO / OH is 1, followed by the addition of toluene so that the concentration of the polyurethane pre-polymer was 90% by weight, and mixing and stirring well to prepare a coating liquid. This coating liquid was coated onto a sintered ePTFE film manufactured by Japan Gore-Tex Inc. (thickness: 50 μm, maximum pore diameter: 0.3 μm, porosity: 80%, rupture elongation percentage in transverse direction as determined in a tensile test: 260%), and cured by heating to obtain a multilayer film in which the thickness of the polyurethane resin layer was 25 μm (thickness of impregnated portion: 15 μm, thickness of surface portion: 10 μm). Next, this multilayer film was subjected to continuous elongation treatment in the transverse direction under the conditions shown in Table 1 with an apparatus having a tenter that spreads apart in a hea...

example 2

[0097]An elastic composite film was produced under the same conditions as Example 1 with the exception of using an elongation temperature of 170° C., elongation factor of 1.6 times in the transverse direction, and elongation speed of 13% / sec. The evaluation results are shown in Table 1. A film having superior elastic properties was obtained having an elongation percentage of 42% in the transverse direction, an elongation recovery rate of 85% and stress of 1.4 N / 15 mm during 10% elongation, by increasing the elongation factor and setting a faster elongation speed.

TABLE 1ElongationElongationElongationpercentagerecoveryfactor ininrate inStressElongationtransverseElongationtransversetransverseduring 10%temperaturedirectionspeeddirectiondirectionelongationNo.(° C.)(times)(% / sec)(%)(%)(N / l5 mm)Ex. 11501.5635851.5Comp.1501.5119802.6ex. 1Comp.2201.565502.7ex. 2Ex. 21701.61342851.4

example 3

[0098]An adhesive manufactured by Nippon NSC Ltd. (“BondMaster”) was transferred in the form of dots on the sintered ePTFE film side of the elastic composite film of Example 2 using a gravure roller having a transfer surface area of 40%, followed by laminating a knit cloth (Nylon / Spandex blend: 75 / 25, gauge: 28G, weight: 58 g / m2, transverse direction elongation percentage: 150%, elongation recovery rate: 95%) onto the transfered side, and applying pressure to obtain a bi-layer structured, elastic composite fabric. The resulting elastic composite fabric had elastic characteristics of an elongation percentage of 35% in the transverse direction and elongation recovery rate of 93%. In addition, the adhesive durability between the film and liner fabric of this laminate was evaluated based on the presence or absence of the peel-off by visual observation of a sample following 100 hours of continuous agitation laundering using tap water containing no detergent at a bath ratio of 1 / 60, bath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation recovery rate | aaaaa | aaaaa |

| elongation recovery rate | aaaaa | aaaaa |

| elongation recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com