Device for Cleaning Exhaust Gas of Internal Combustion Engine

a technology for cleaning exhaust gas and internal combustion engines, which is applied in the direction of machines/engines, exhaust treatment electric control, separation processes, etc., can solve the problems of insufficient oxidation reaction, difficult to completely oxidize pm exhausted from the engine and remove the same, and worse fuel consumption, etc., to achieve excellent effect and effectively usable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

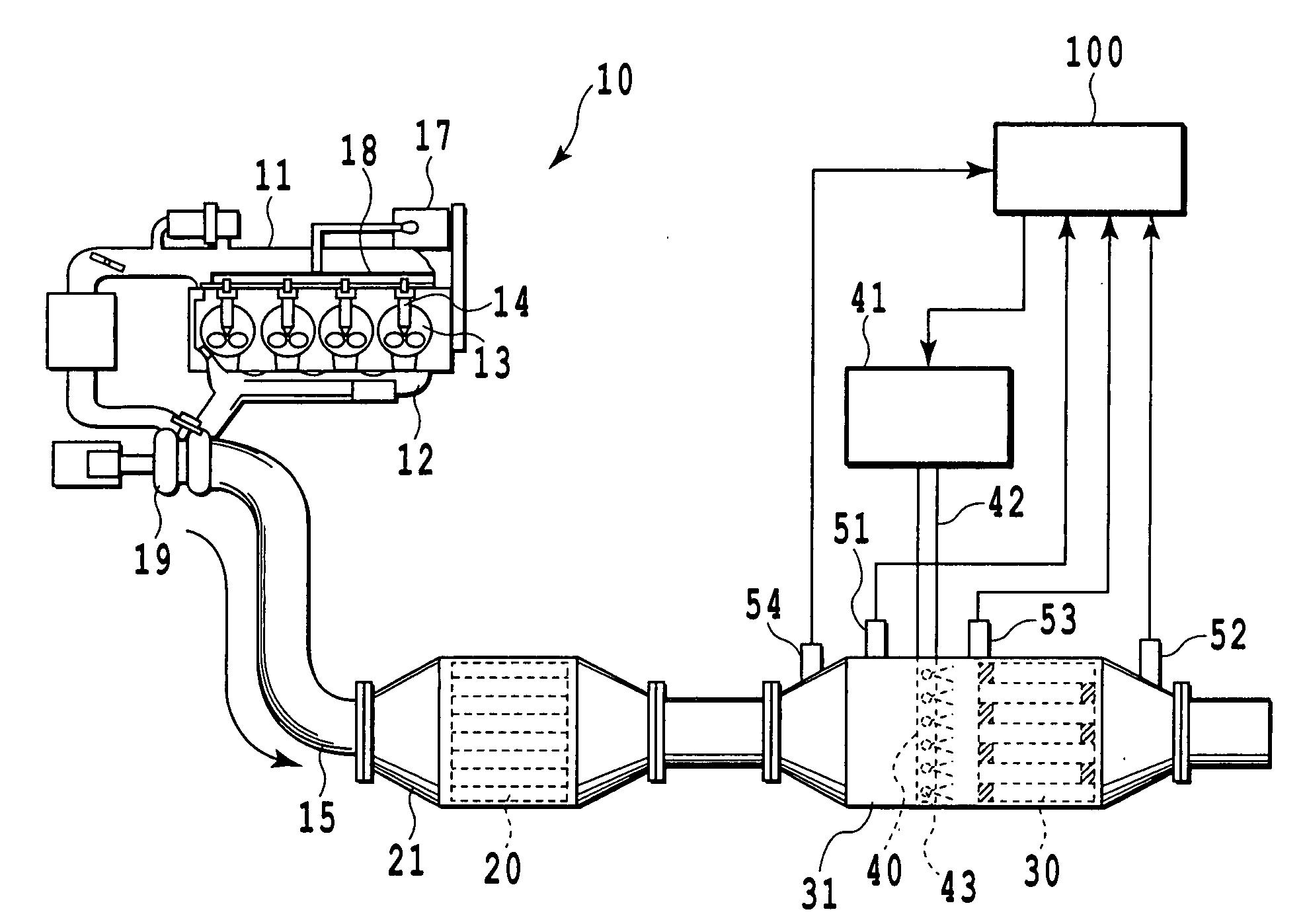

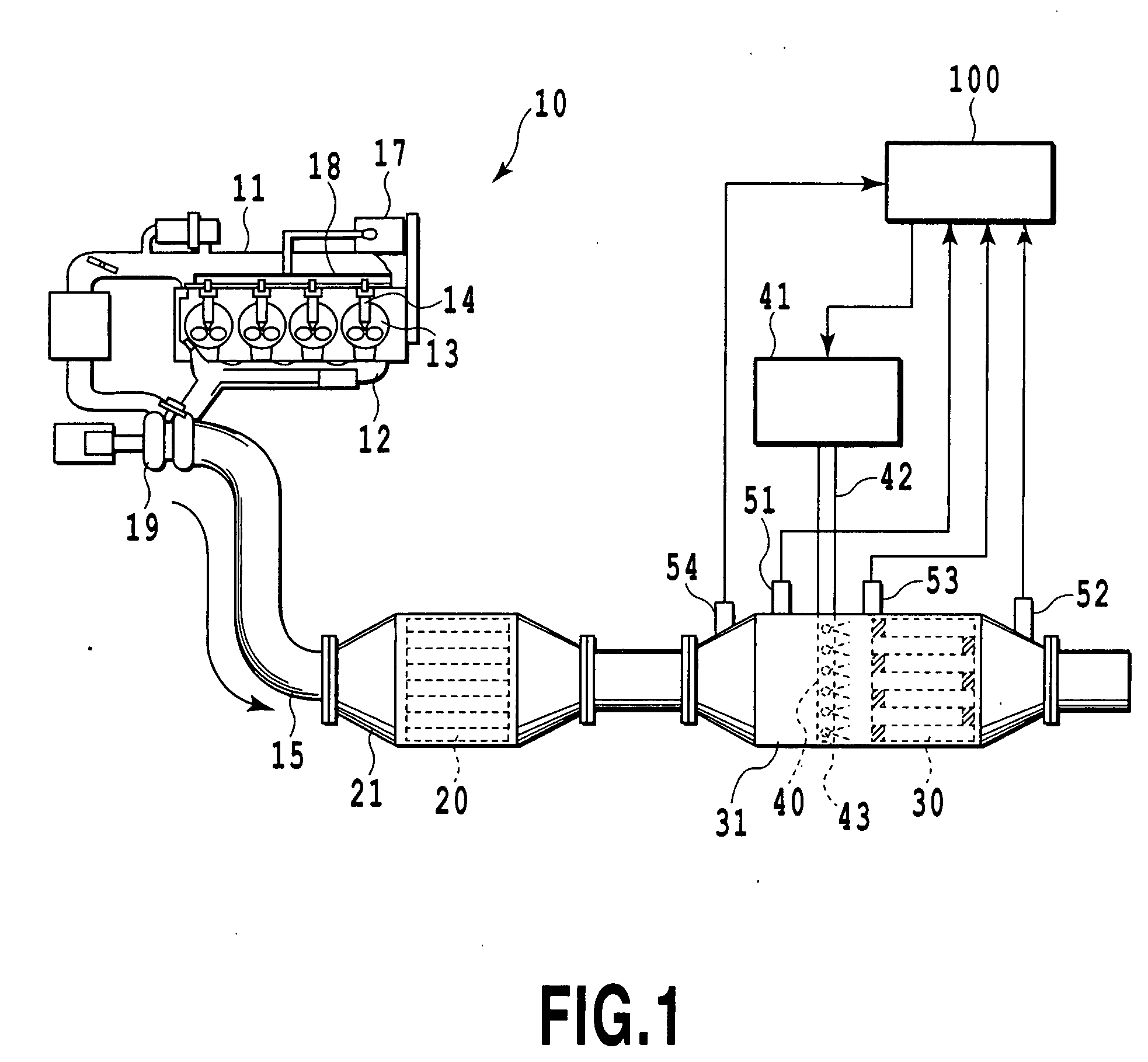

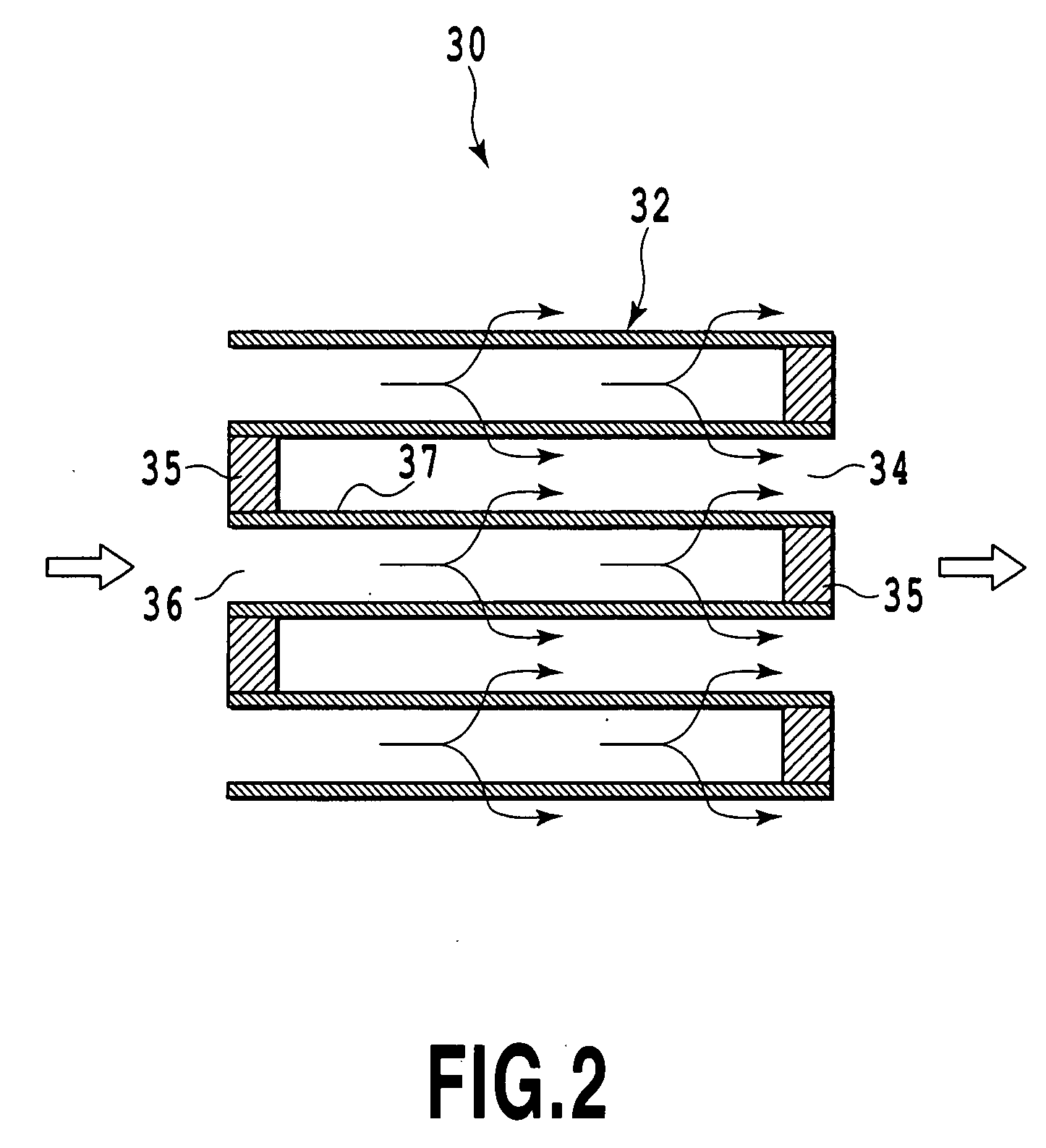

[0041]FIG. 1 diagrammatically illustrates a system of a device for cleaning exhaust gas of an internal combustion engine according to a first embodiment of the present invention, wherein reference numeral 10 denotes a compression ignition type internal combustion engine; i.e., a diesel engine, 11 denotes an intake manifold communicated with an intake port, 12 denotes an exhaust manifold communicated with an exhaust port, and 13 denotes a combustion chamber. According to this embodiment, fuel supplied from a fuel tank not shown to a high pressure pump 17 is sent thereby to a common rail 18 and stored there under a high pressure. The highly pressed fuel in the common rail 18 is directly injected from a fuel injection valve 14 to the combustion chamber 13. Exhaust gas from the diesel engine 10 flows via the exhaust manifold 12 and a turbocharger 19 and reaches an exhaust gas passage 15 provided downstream thereof, wherein the exhaust gas is cleaned and discharged to an outer air. In th...

second embodiment

[0099]Next, a second embodiment according to the present invention will be described with reference to the attached drawings. In this regard, the same reference numerals are used in the drawings for denoting the same parts as those in the first embodiment, and the detailed explanation thereof will be eliminated.

[0100]FIG. 10 diagrammatically illustrates a system of a device for cleaning exhaust gas of an internal combustion engine according to the second embodiment. As illustrated, in the second embodiment, second ozone feeding nozzles 90 are provided as separate means for feeding ozone (O3) in an exhaust gas passage 15 on the upstream side from NOx catalyst. The second ozone feeding nozzles 90 are of the same structure as the ozone feeding nozzles 40 disposed upstream from DPF 30. The second ozone feeding nozzles 90 and the ozone feeding nozzles 40 are connected to a flow rate control unit 91, and the flow rate control unit 91 is connected to the ozone generator 41. The flow rate c...

third embodiment

[0128]Next, a third embodiment according to the present invention will be described with reference to the attached drawings. In this regard, the same reference numerals are used in the drawings for denoting the same parts as those in the first embodiment, and the detailed explanation thereof will be eliminated.

[0129]FIG. 15 diagrammatically illustrates a system of a device for cleaning exhaust gas of an internal combustion engine according to the second embodiment. As illustrated, in the third embodiment, an oxidation catalyst 110 is disposed in a casing 21 common to the NOx catalyst 20.

[0130]In the first embodiment, as described before, when the NOx catalyst 20 is of a storage reduction type, the rich spike (the separate injection or the post injection of gas oil) is executed for releasing or reduction-cleaning NOx stored in the NOx catalyst 20. Alternatively, if such rich spike is not executed, HC in the exhaust gas passes through the NOx catalyst 20 with substantially no interfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com