Impulse combustion cleaning system and method

a cleaning system and impulsive technology, applied in the direction of cleaning using liquids, combustion types, lighting and heating apparatuses, etc., can solve the problems of reducing the efficiency of the system, so as to achieve the effect of effective and reliable impulse cleaning system and removal of built-up deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Soot or other buildup on heat exchanger surfaces in industrial boilers can cause losses in the overall efficiency of the boiler due to a reduction in the amount of heat that is actually transferred into a working fluid. This is often reflected by an increase in the exhaust gas temperature from the process, as well as an increase in the fuel-burn rate required to maintain steam production and a given energy output. Traditionally, the complete removal of buildup from the heat exchanger surfaces requires the boiler to be shut down while a cleaning process is performed. Online cleaning techniques generally have high maintenance costs or incomplete cleaning results.

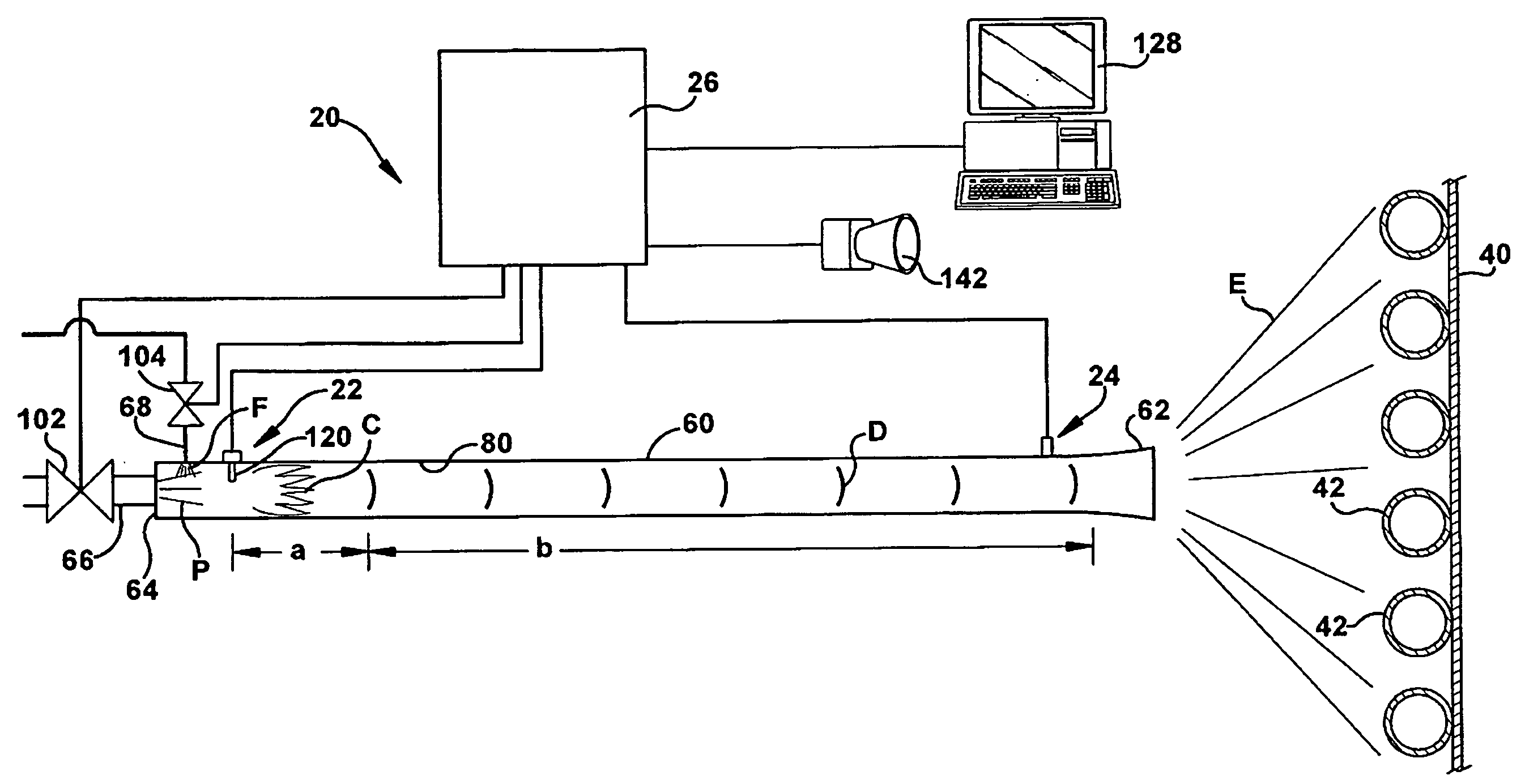

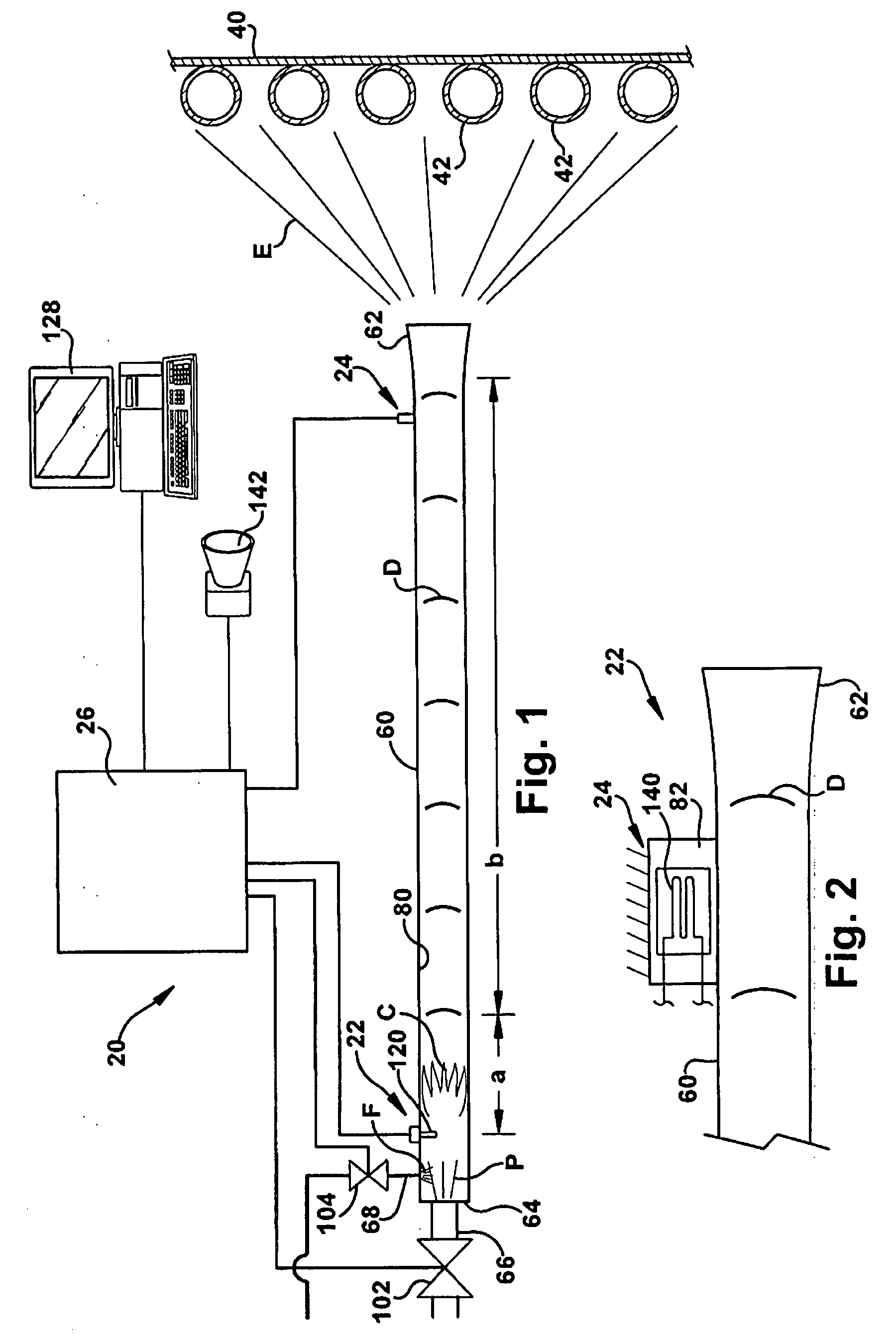

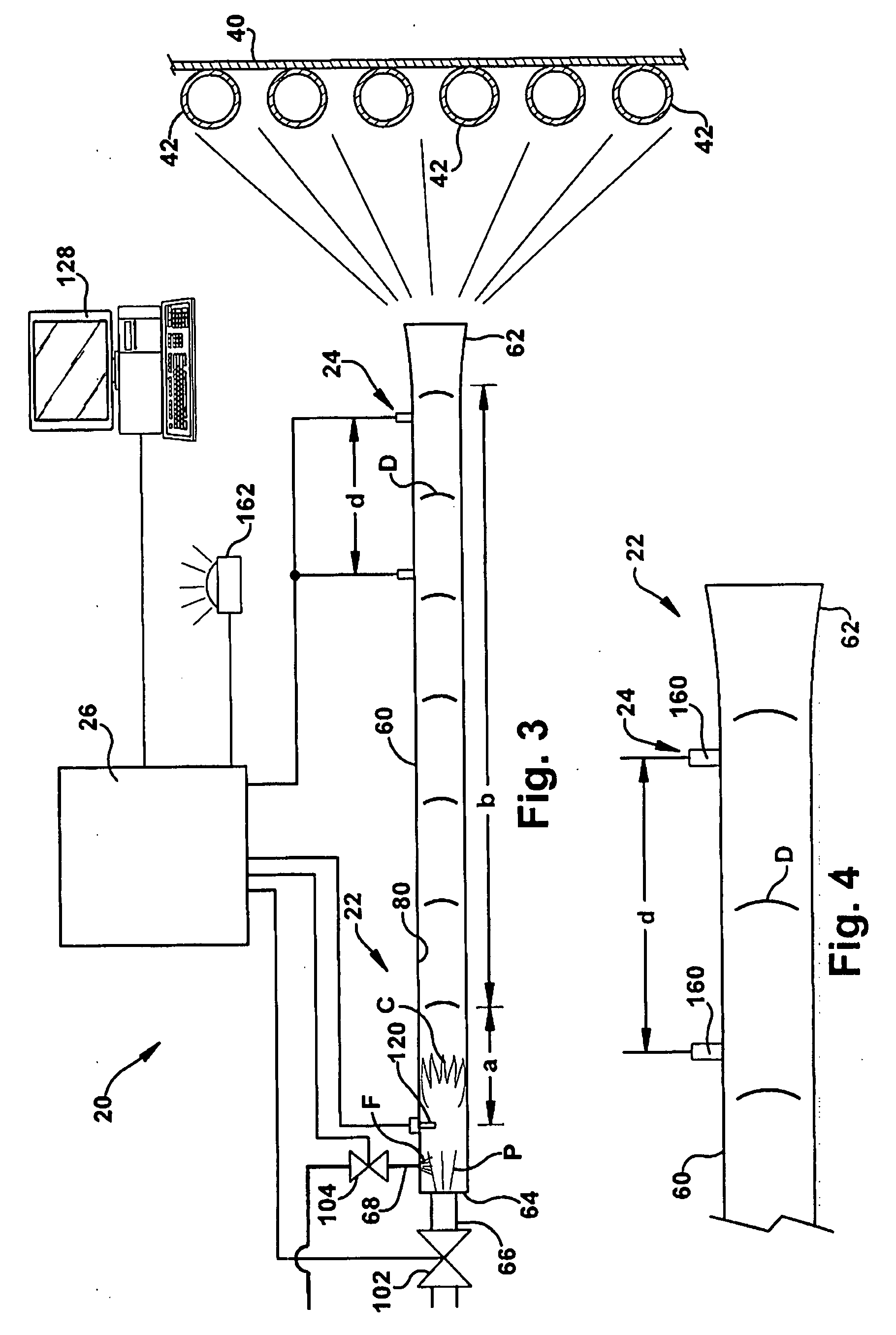

[0015]In one aspect of the invention, an impulse cleaning system located external to the boiler is used to generate a series of detonations or quasi-detonations that are directed into a fouled portion of the boiler. The resulting impulse waves impact boiler surfaces and loosen buildup from the surfaces. The loosened debr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com