Single-layered arch support insole to be inserted into shoe

a single-layer, arch support technology, applied in the direction of insoles, uppers, bootlegs, etc., can solve the problems of manufacturing costs, increasing the number of manufacturing processes, and unable to adequately support the arch of the wearer's foot, so as to minimize fatigue on walking, prevent deformation and buckling, and even distribution of wearer's weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

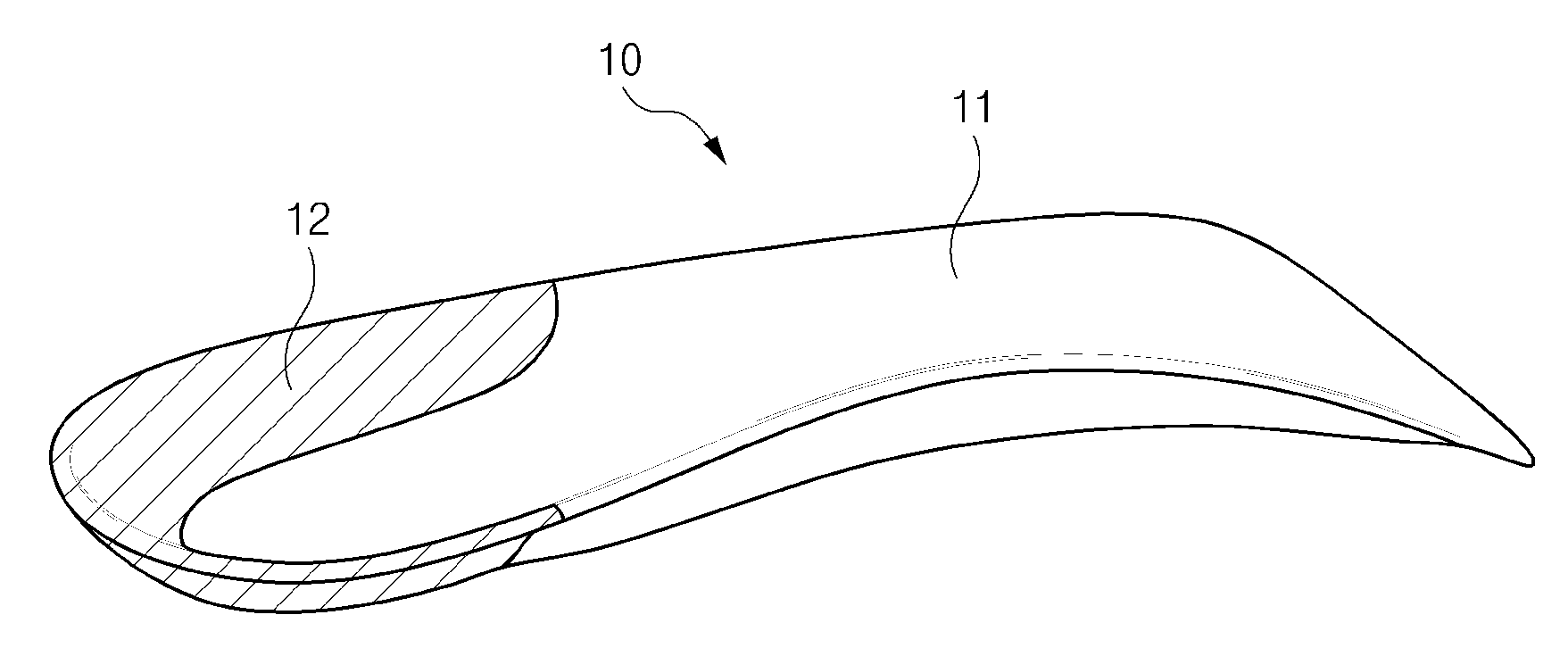

[0046]FIG. 1 is a perspective view of an insole in accordance with the first embodiment of the present invention, and FIG. 2 is a plan view of the in accordance with the first embodiment of the present invention.

[0047]The insole 10 in accordance with the first embodiment of the present invention includes an insole main body 11 corresponding to the shape of sole of a foot, except toes, and a heel support part 12 surrounding the heel of the foot. The insole main body 11 and the heel support part 12 is formed of a single layer and fabricated by plastic materials having different hardness.

[0048]In general, the insole formed of a plastic material such as polypropylene or nylon is manufactured by a plastic molding technology. In general, plastic molding methods are classified into various methods such as injection molding, press molding, transfer molding, rotary molding, thermal molding, blow molding, film blowing, extrusion, calendaring, fiber spinning, and so on. Among them, the injecti...

second embodiment

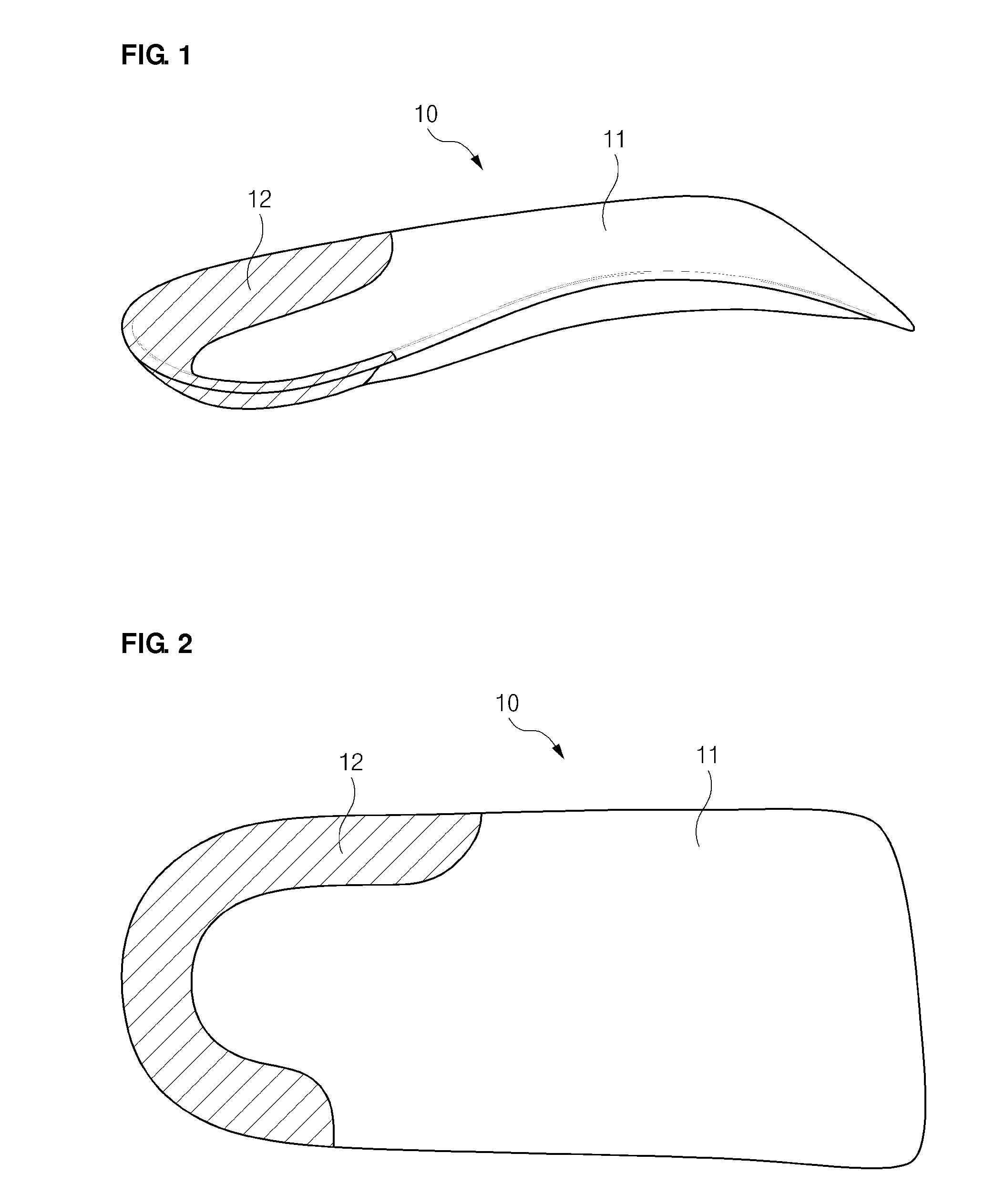

[0057]FIG. 3 is a perspective view of an insole in accordance with the second embodiment of the present invention, and FIG. 4 is a plan view of the insole in accordance with the second embodiment of the present invention.

[0058]The insole 20 in accordance with the second embodiment of the present invention further includes an anti-slip part 13 to prevent slippage of a front part of the insole 20. The heel support part 12 and the anti-slip part 13 has hardness different from the insole main body 11 such that the heel support part 12 smoothly wraps the heel and the anti-slip part 13 minimize movement of the insole 20 when the insole 20 is inserted into a shoe. The second embodiment is similar to the first embodiment, except the above description, and thus, overlapping description thereof will not be repeated.

[0059]In a manufacturing method thereof, similar to the first embodiment, a first plastic material is inserted into a first cavity to primarily form the insole main body 11, and th...

third embodiment

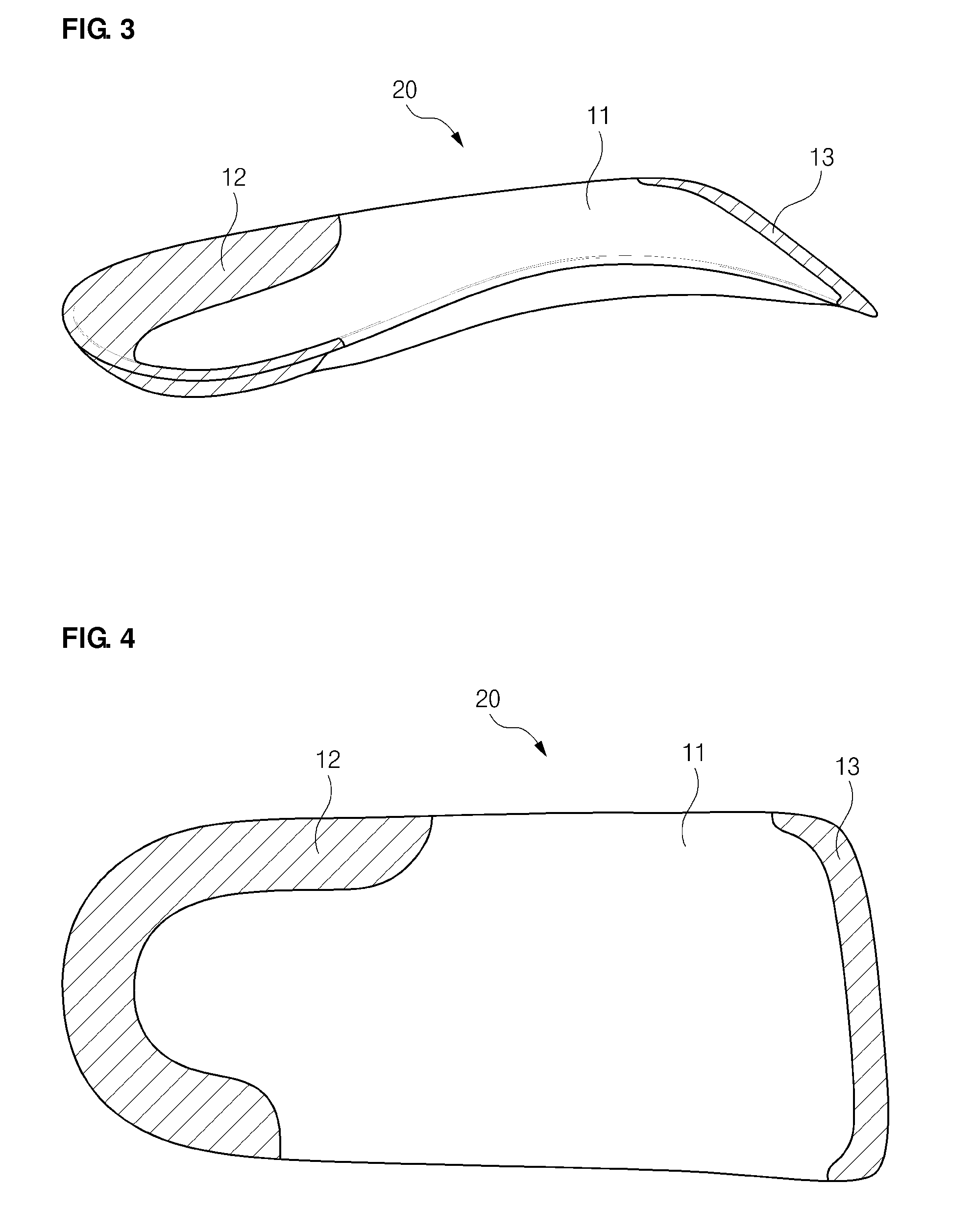

[0061]FIG. 5 is a perspective view of an insole in accordance with the third embodiment of the present invention, FIG. 6 is a plan view of the insole in accordance with the third embodiment of the present invention, FIG. 7 is a bottom view of the insole in accordance with the third embodiment of the present invention, and FIG. 8 is a side view of the insole in accordance with the third embodiment of the present invention. Meanwhile, in this embodiment, description overlapping the aforementioned embodiments will not be repeated.

[0062]The insole 30 in accordance with the third embodiment of the present invention, which is characterized by an arch support part different from the first and second embodiments, generally includes an insole main body 11 configured to include a portion or the entire of an arch support part curvedly projecting upward to support the arch of a wearer's foot, and a heel support part 12 coupled to a rear part of the insole main body. The insole main body 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com