Problem detection apparatus and method in exhaust purifying apparatus

a technology of problem detection and exhaust purification, which is applied in mechanical equipment, machines/engines, separation processes, etc., can solve problems such as non-diagnosis, and achieve the effect of increasing the reliability of the problem detection apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

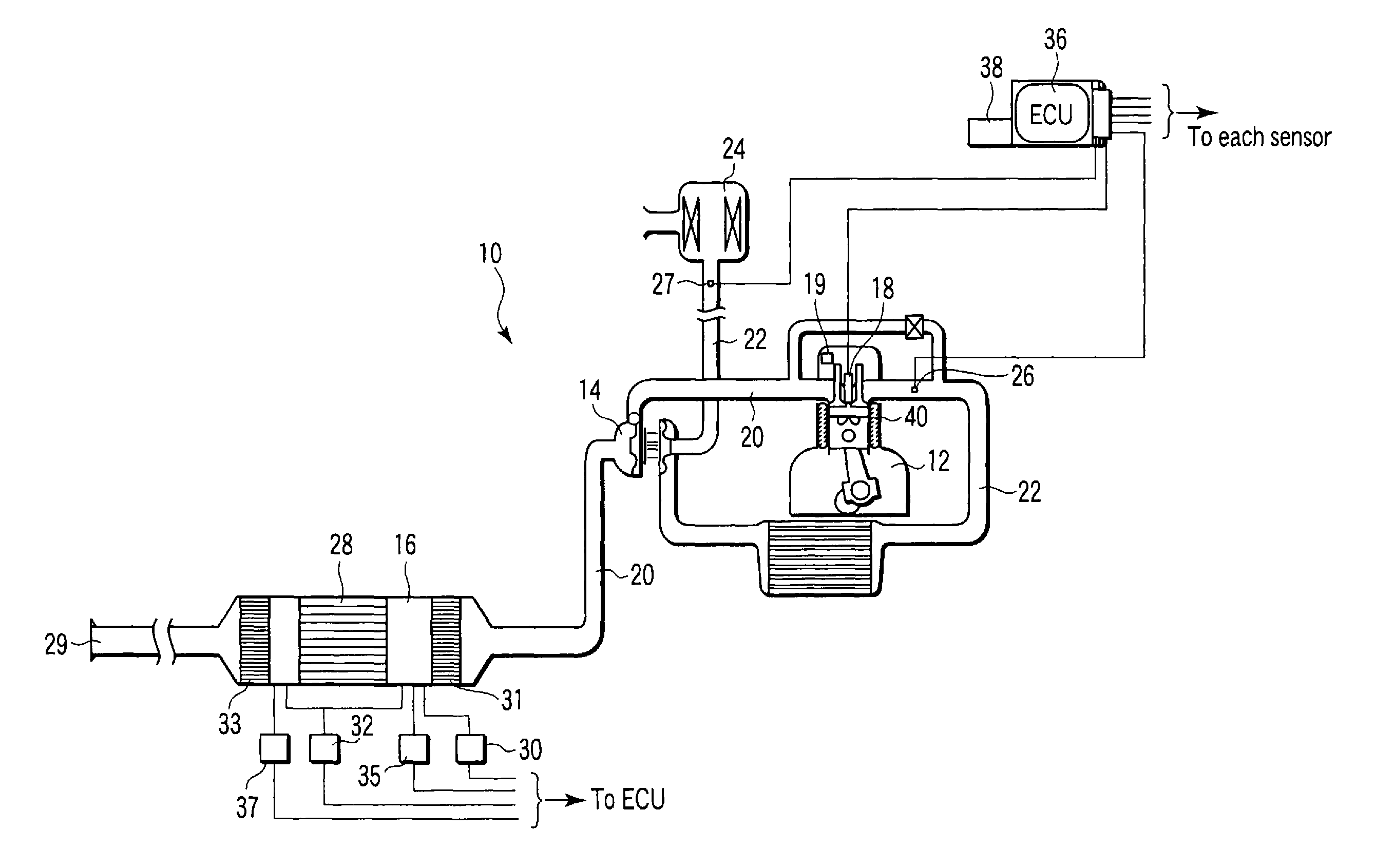

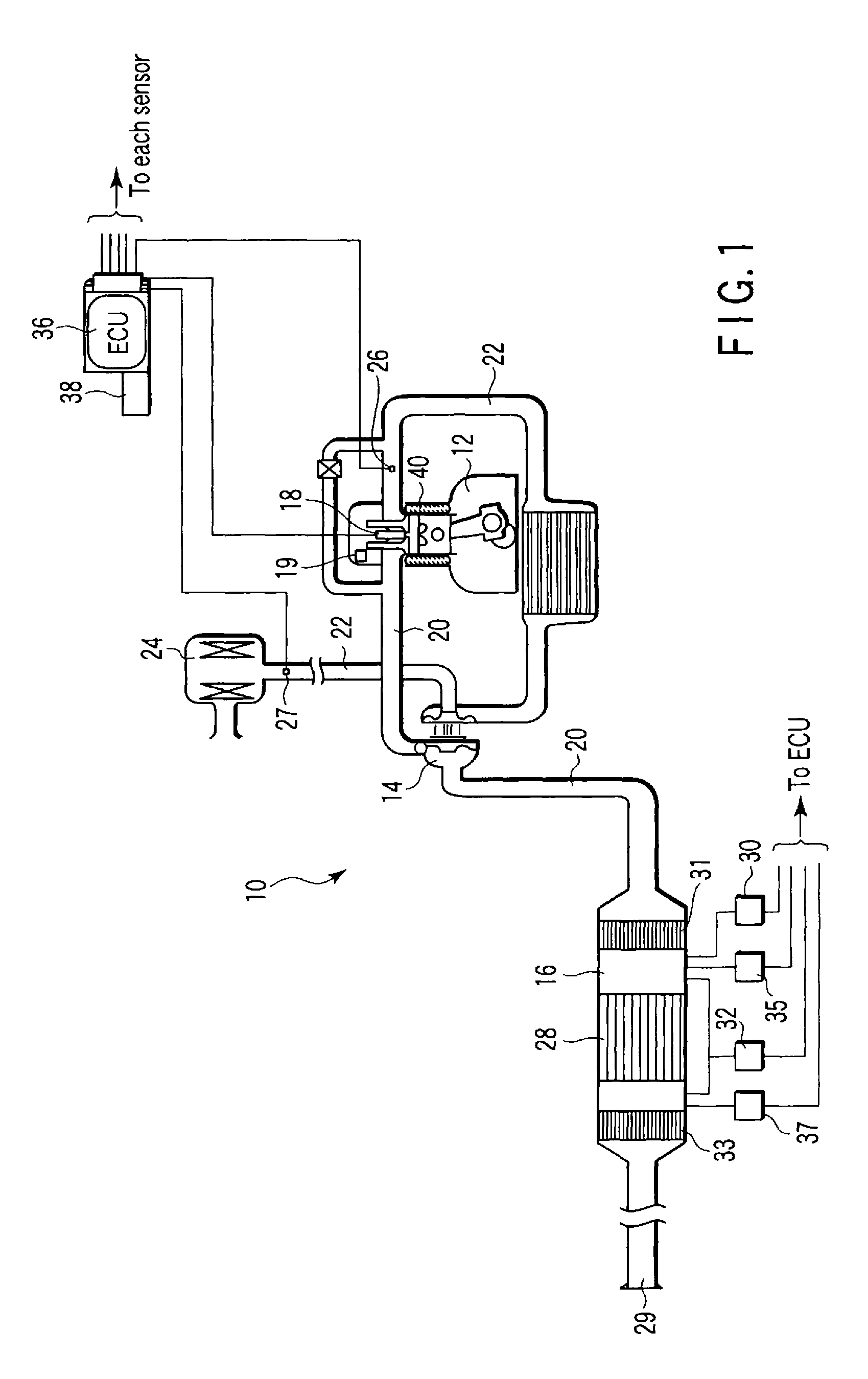

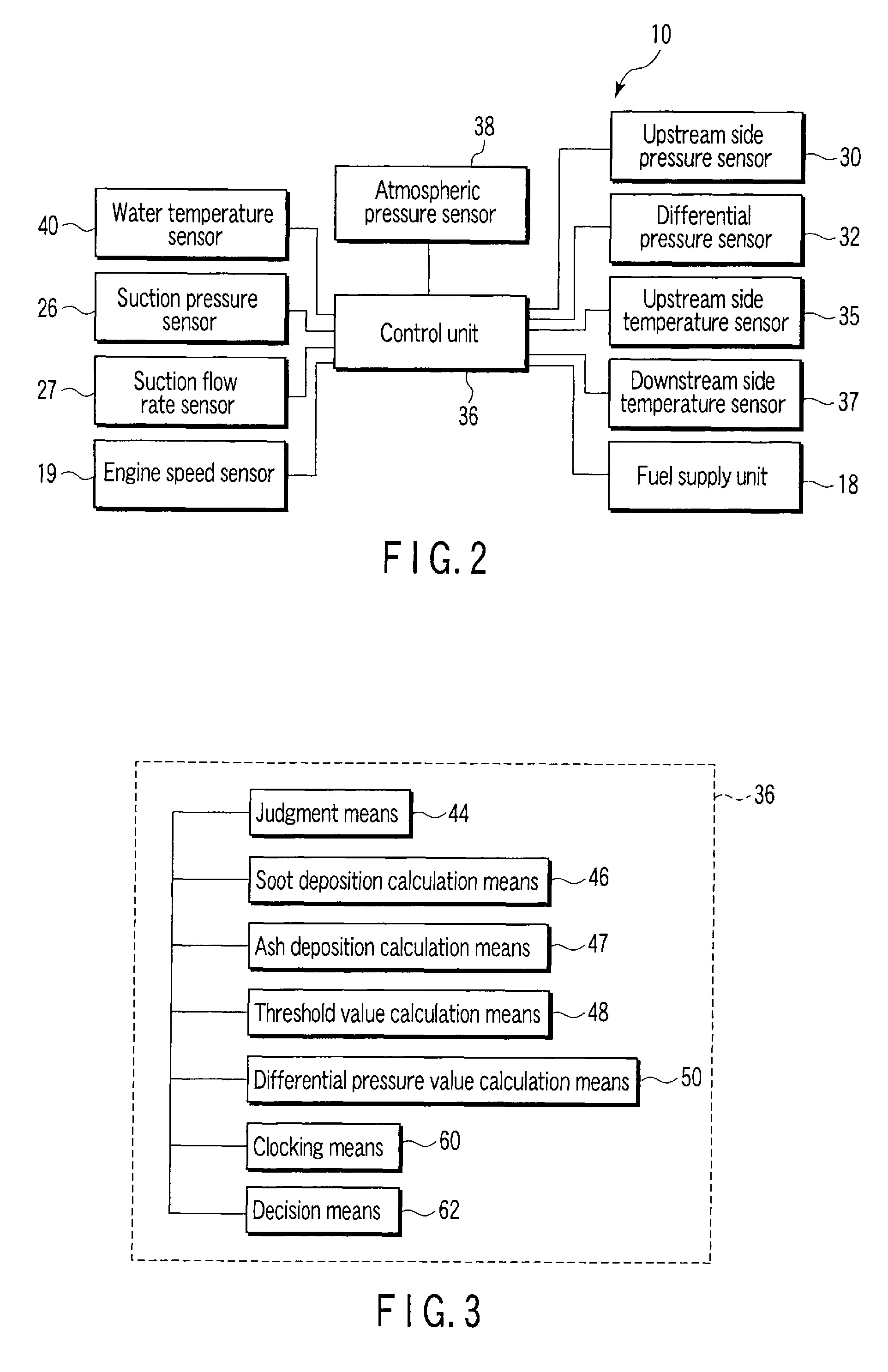

[0043]Explanations will be given on an embodiment of a filter problem detection apparatus and method according to the present invention with reference to the accompanying drawings.

[0044]FIG. 1 shows the configuration of an engine 12 having a filter problem detection apparatus 10, as an internal combustion engine. The engine 12 is a diesel engine comprising a turbo charger 14, a DPF unit 16, a fuel supply unit 18, and an engine speed sensor 19. The turbo charger 14 is connected to an exhaust pipe 20 as an exhaust path, and a suction pipe 22 as a suction path. The turbo charger 14 pressurizes outside air suctioned through an air cleaner 24 by using an exhaust pressure, and feeds the pressurized air to the engine 12.

[0045]The suction pipe 22 is provided with a suction pressure sensor 26 to detect the pressure in the suction pipe 22, or the boost pressure by the turbo charger 14, and a suction flow rate sensor 27 to detect a flow rate in the suction pipe 22. The engine 12 is not limited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com