Electronic Assemblies without Solder and Methods for their Manufacture

a technology of electronic components and soldering operations, which is applied in the direction of stacked and attached pcbs, semiconductor/solid-state device details, manufacturing tools, etc., can solve the problems of high toxic substances, dangerous fumes produced by soldering operations, and potential hazards for workers, so as to reduce costs and complexity, shorten manufacturing cycle time, and reduce the reliability of pcbs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

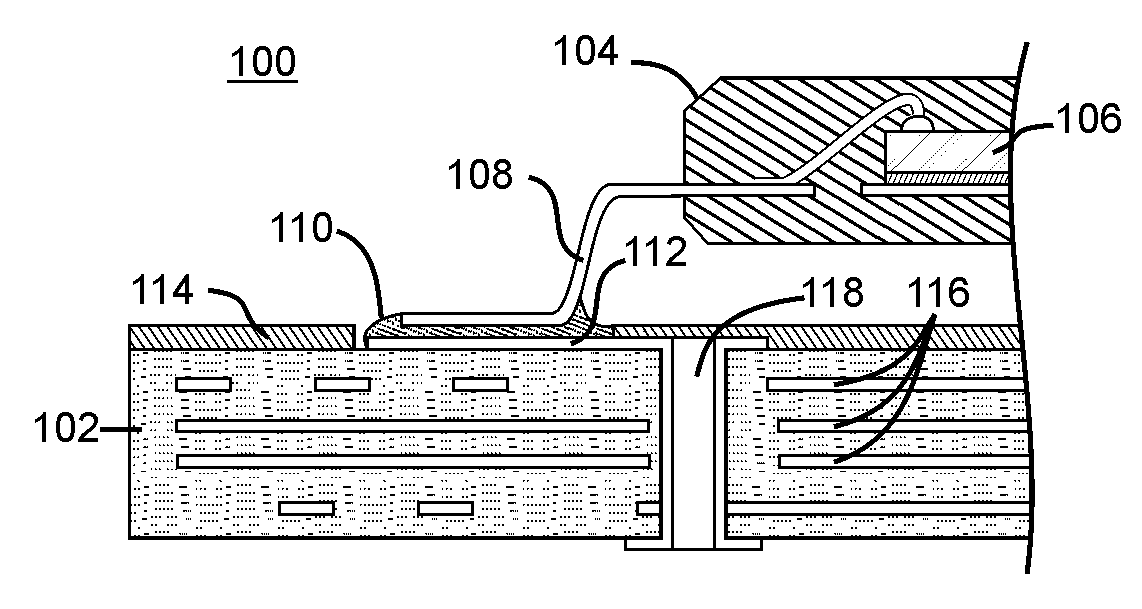

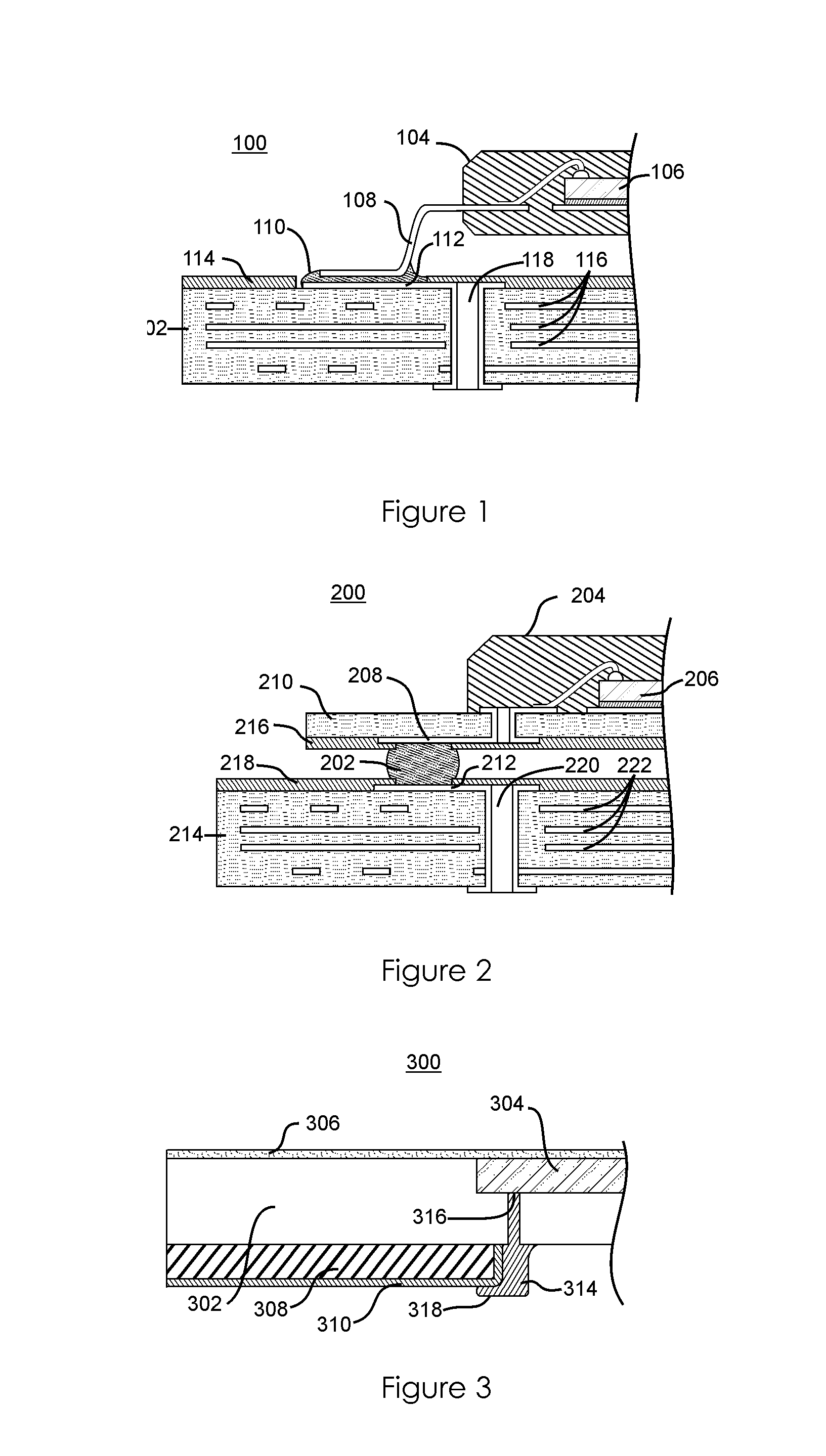

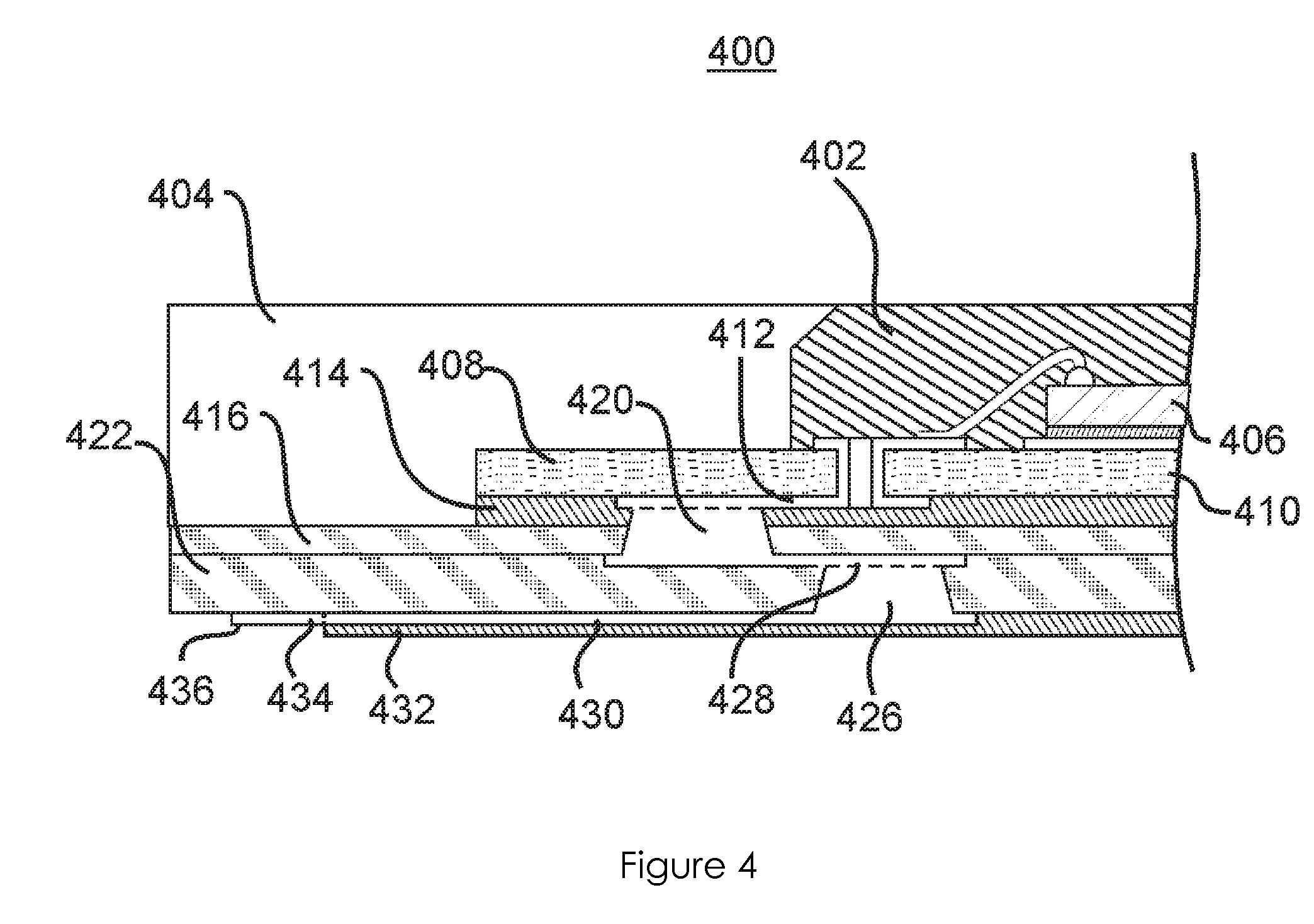

[0069]In the following description and in the accompanying drawings, specific terminology and drawing symbols are set forth to provide a thorough understanding of the present invention. In some instances, the terminology and symbols may imply specific details that are not required to practice the invention. For example, the interconnection between conductor elements of components (i.e., component I / O leads) may be shown or described as having multi-conductors interconnecting to a single lead or a single conductor signal line connected to multiple component contacts within or between devices. Thus each of the multi-conductor interconnections may alternatively be a single-conductor signaling, control, power or ground line and vice versa. Circuit paths shown or described as being single-ended may also be differential, and vice-versa. The interconnected assembly may be comprised of standard interconnections; microstrip or stripline interconnections and all signal lines of the assembly m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical conductivity | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com