Ice maker contamination control system

a technology for controlling systems and ice makers, which is applied in the field of ice makers, can solve problems such as contamination of ice produced, and achieve the effects of reducing ambient contamination and increasing ultraviolet radiation reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

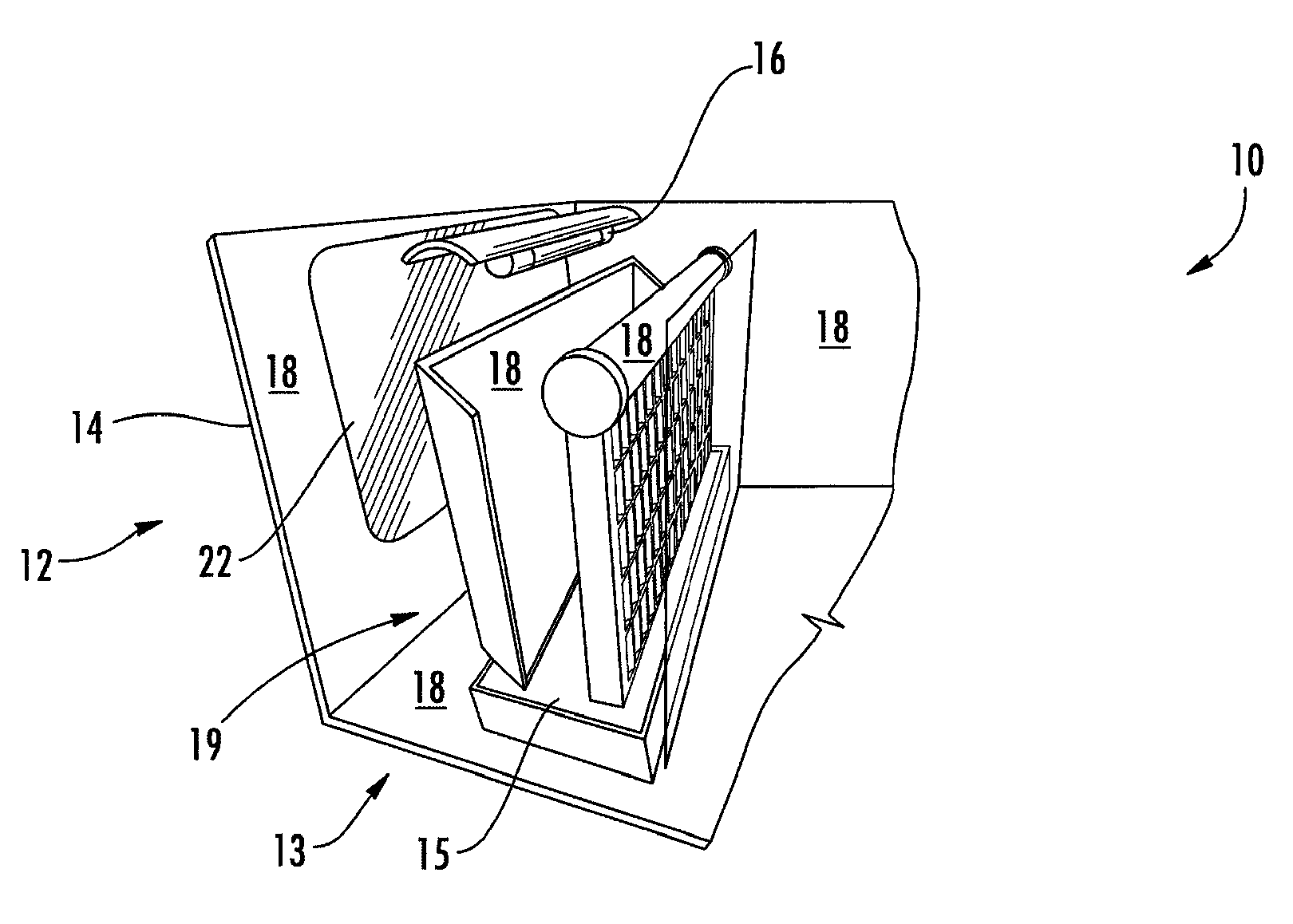

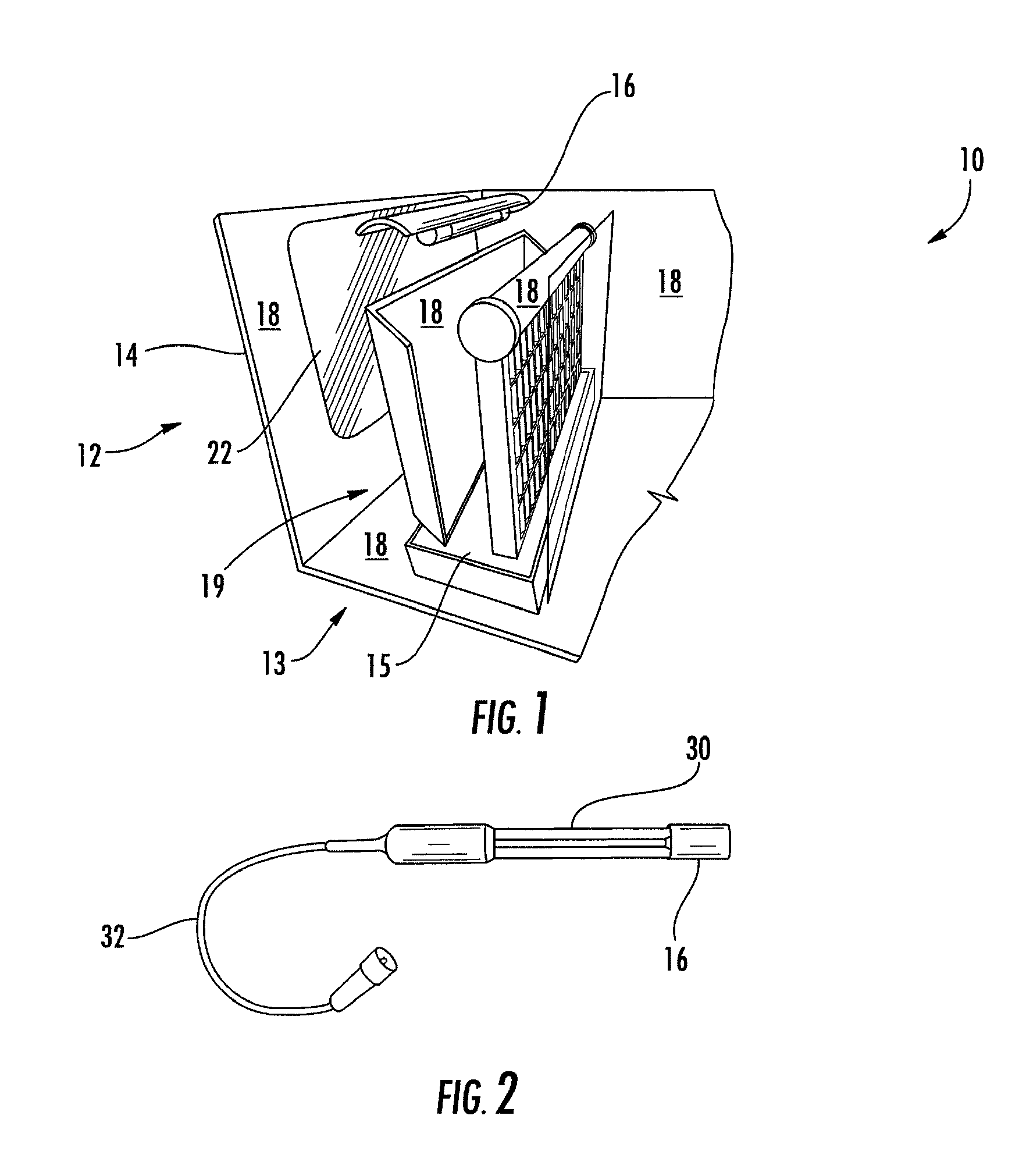

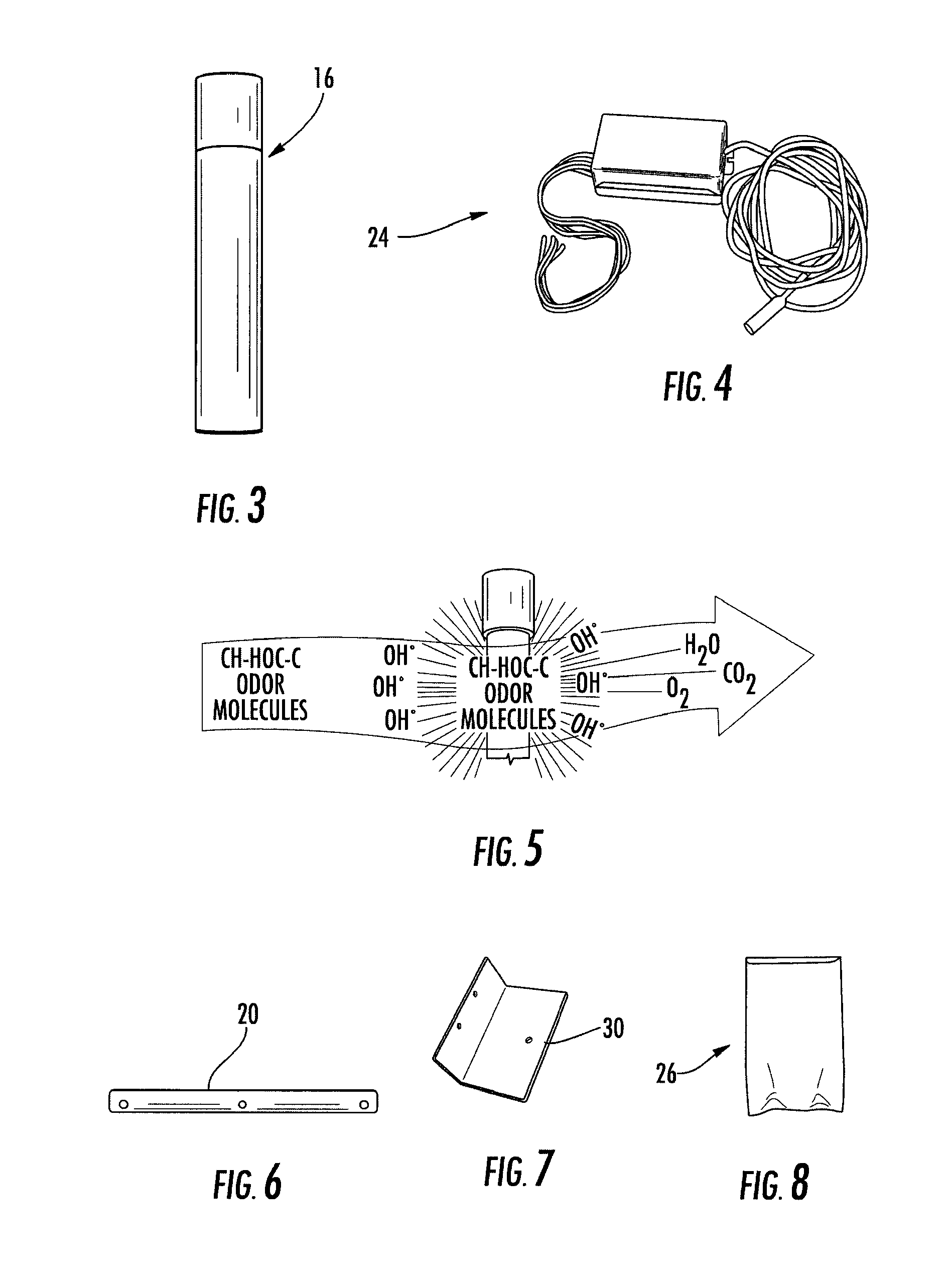

[0022]As shown in FIGS. 1-9, an ice maker contamination control system 10 is disclosed for decontaminating components of an ice maker 12, and in particular, components of an ice formation housing 14. The ice maker contamination control system 10 may be configured to kill fungi, bacteria, viruses, yeast and mold within the ice formation housing 14 to prevent illness and disease from ingesting contaminated ice. In at least one embodiment, the ice maker contamination control system 10 may include at least one ultraviolet light source 16 adapted to be positioned in the ice formation housing 14 of an ice maker 12 for emitting ultraviolet light in the ice formation housing 14 for emitting ultraviolet light to irradiate internal surfaces 18 of the ice formation housing 14, ice formation components 13, and ambient environment 19 surrounding the ice formation components 13 within the ice formation housing 14.

[0023]As shown in FIG. 1, the ice maker contamination control system 10 may be adapt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com