Universal Lids and Methods for Making and Using the Same

a technology of universal lids and lids, applied in the direction of caps, liquid handling, containers preventing decay, etc., can solve the problems of affecting the use of lids configured for a particular container, affecting the use of lids, etc., and achieves enhanced thermal time-temperate indication and increased vacuum levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0143]Temperature indicating lid composition: A universal lid composition was prepared using VERSAFLEX CL2000X, a thermo polymer elastomer (GLS Corp.). The resin was extruded using a 1 inch 3 zone extruder set at 250° F., 390° F., and 370° F. for zones 1, 2, and 3 respectively. A dried finely ground thermochromic powder (10° C. vermillian, blue, black, yellow, turquoise, pink, brilliant green, brown, or other available colors from Matsui Corp.) was added and blended at 1.5% by weigh and coated onto the CL2000X resin. The resin / composition was extruded at 90 rpm into elongated ingots.

example 2

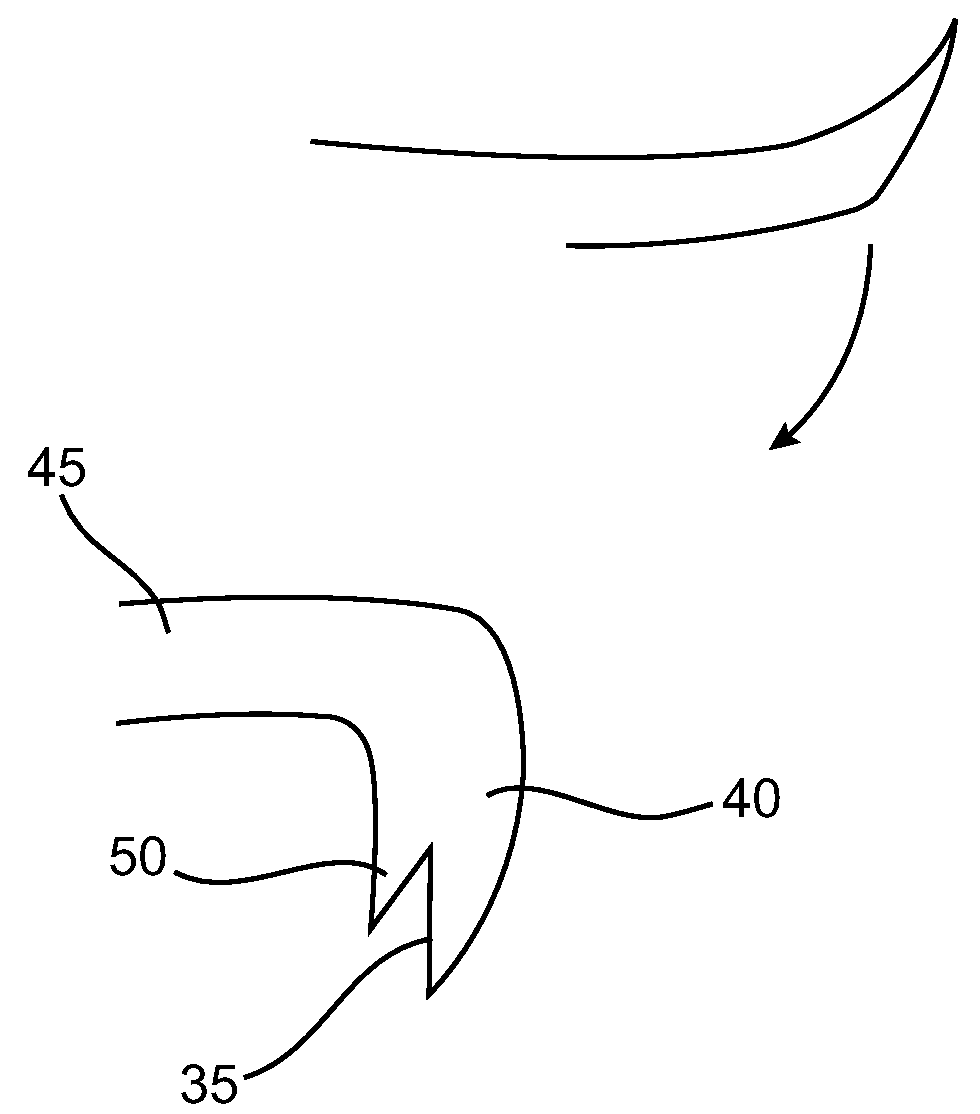

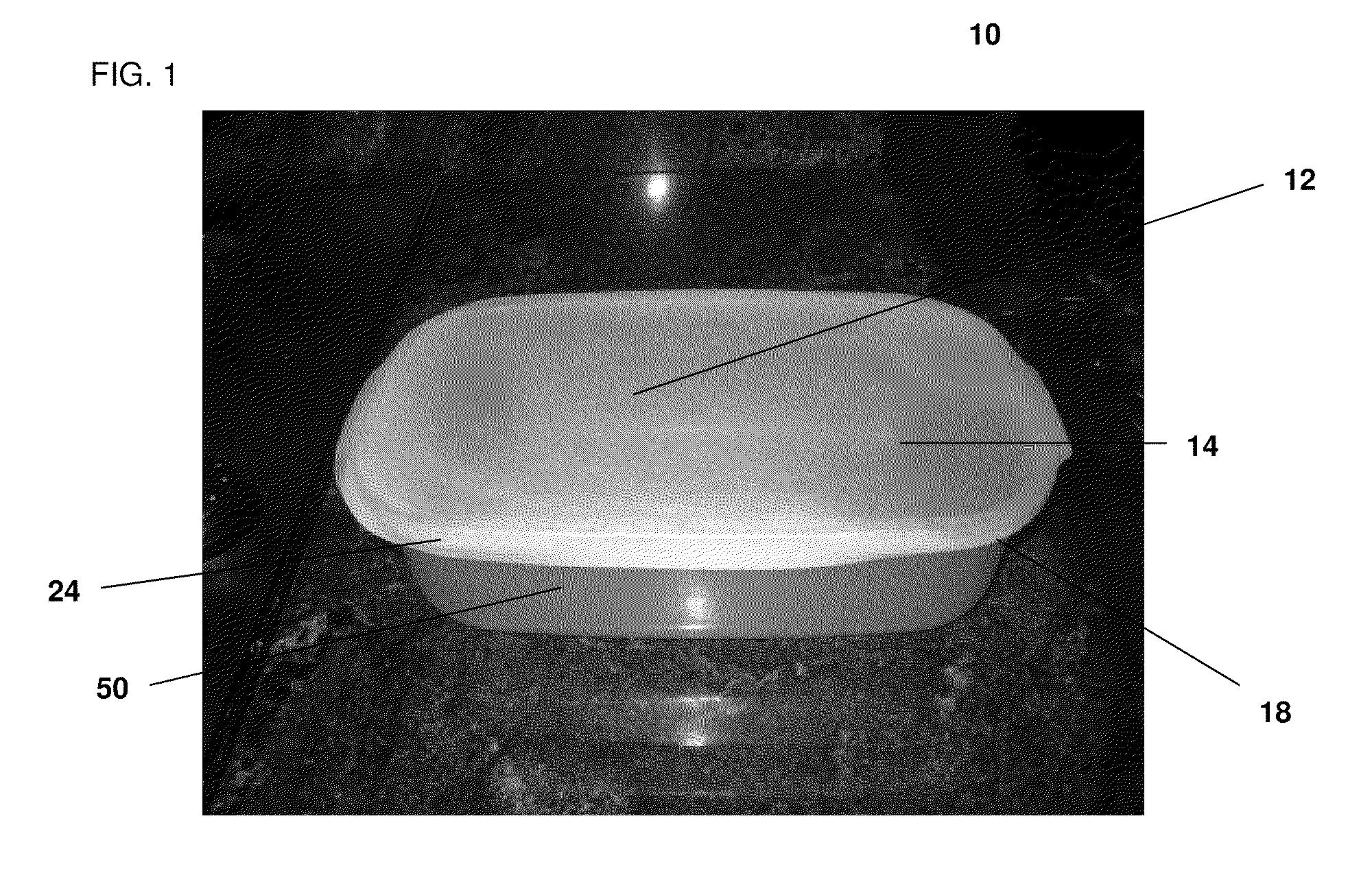

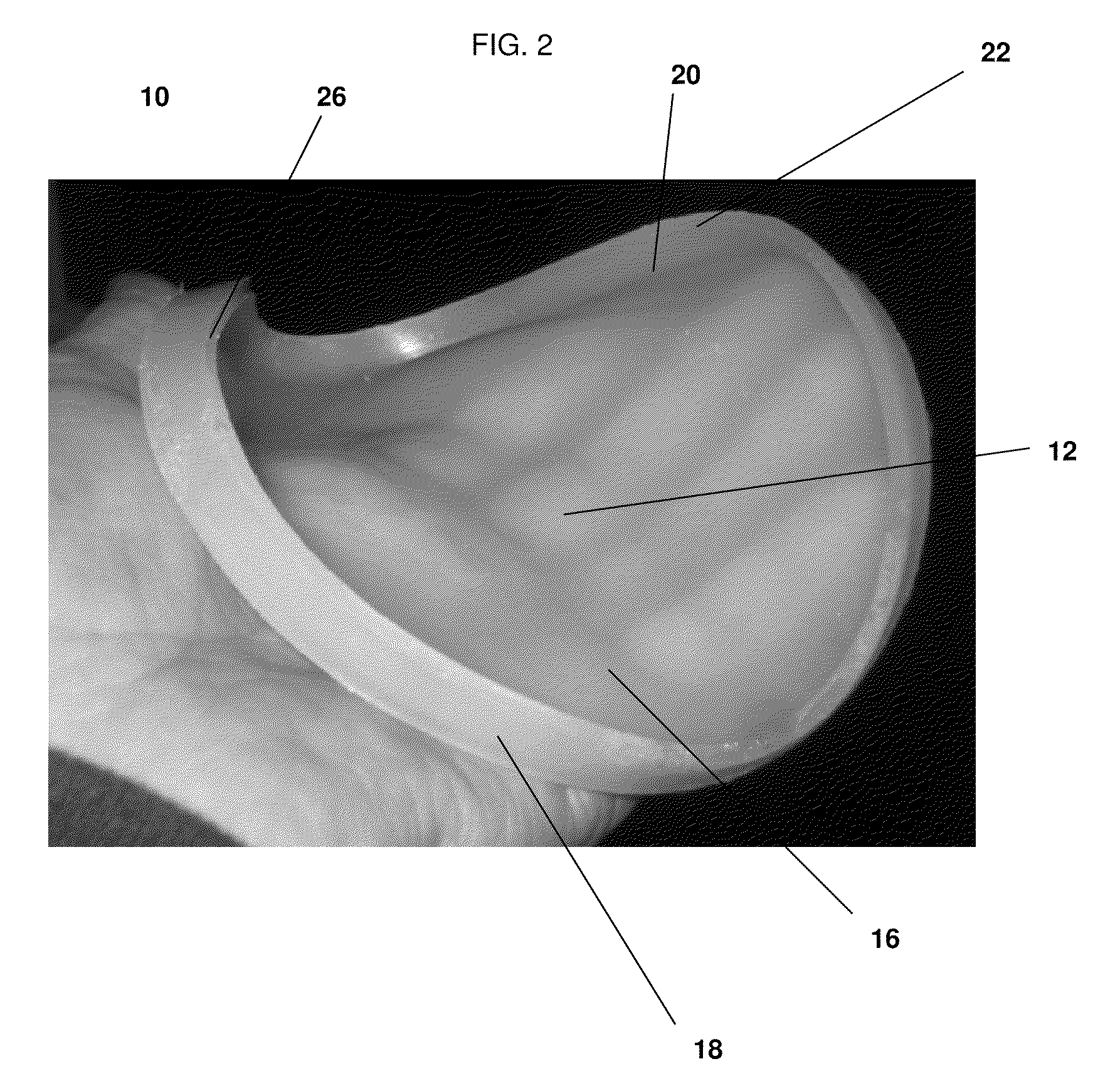

[0144]Compression molded universal lid: The temperature indicating composition in ingot form in Example 1 above was compression molded using a pre-machined aluminum molded (6061) into pre-determined lid shapes comprising a top surface (0.06 inch thick and an undercut edge band). The undercut edge band was 0.125 inches thick and 0.75 inches tall.

example 3

[0145]Temperature indication and utility of a universal lid: The universal lid molded in Example 2 above was stretched over a variety of container types storing liquids, perishables, food types, or other substances. The lid was compressed in the middle to create permanent vacuum for enhanced storage conditions. The lid transitioned from a light translucent clear color to a dark temperature indicating color upon cooling to 10° C. The lid held its vacuum at room temperature, refrigerator temperature, and sub-zero temperatures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com