Refrigerant cycle system

a technology of refrigerant cycle and cycle system, which is applied in the direction of domestic cooling apparatus, piston pumps, lighting and heating apparatus, etc., can solve the problems of large current value inputted into electric motors, significantly worsening of air conditioning etc. in passenger compartments, etc., and achieves the effect of avoiding excessive temperature ris

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

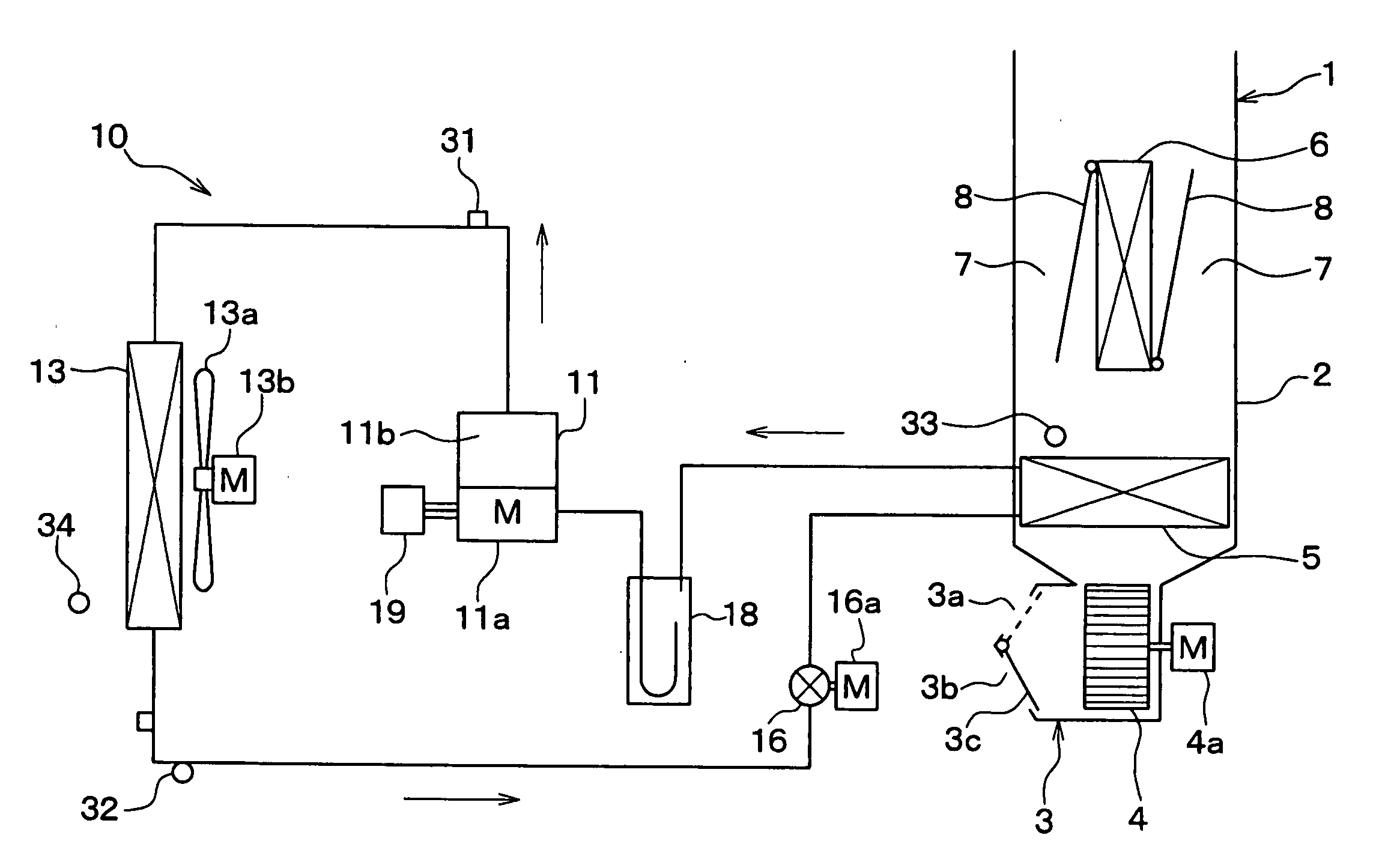

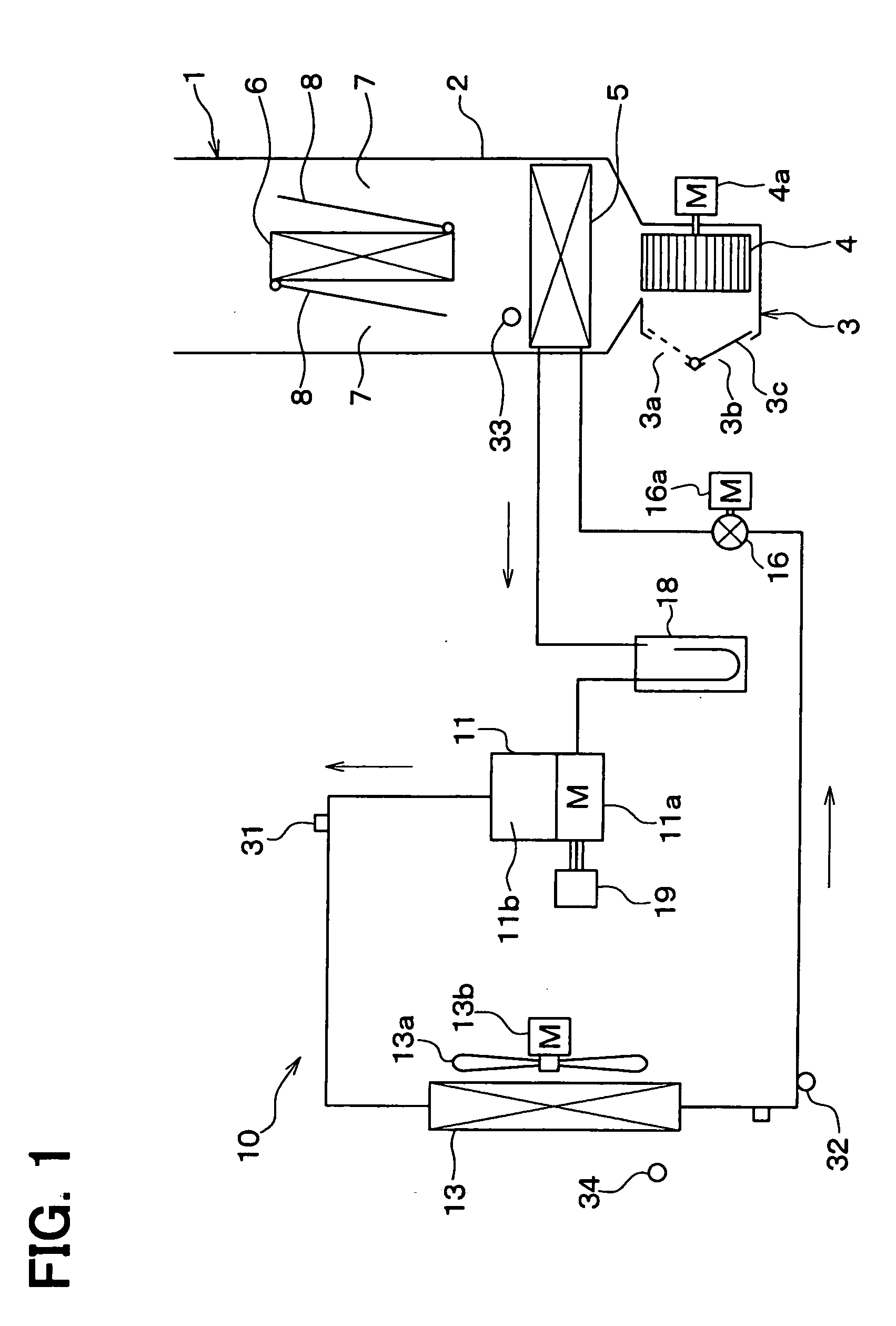

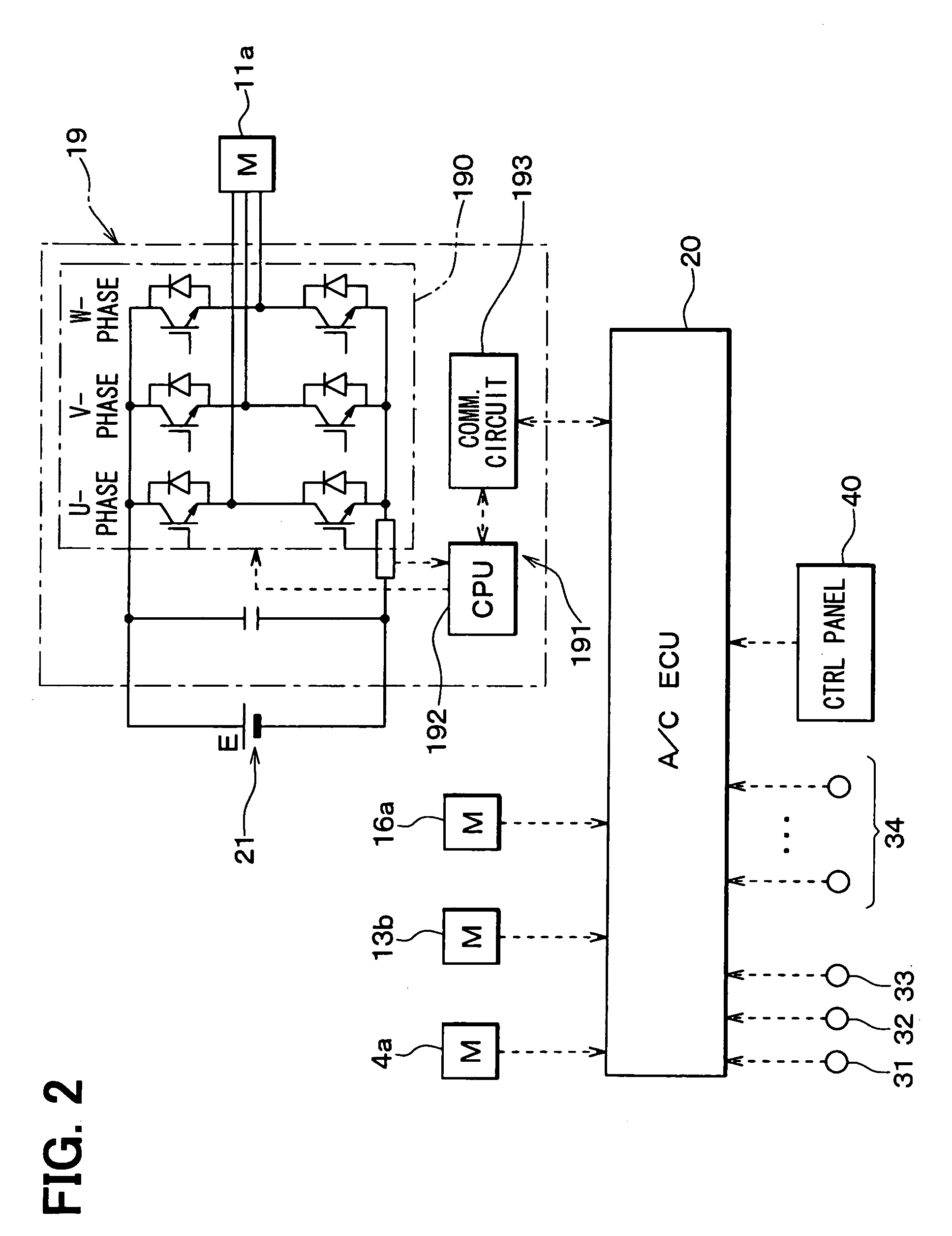

[0019]A first embodiment of the present invention will be described hereafter, referring to FIGS. 1-4. FIG. 1 is a schematic diagram showing an entire construction of a refrigerant cycle system according to the first embodiment, which is applied to a vehicular air conditioning system. As shown in FIG. 1, the vehicular air conditioning system according to the first embodiment has an interior air conditioning unit 1 that is installed inside an instrument panel, which is located at a front-most part of a passenger compartment of a vehicle to form an instrument board etc.

[0020]The interior air conditioning unit 1 has a case member 2 that is made of resin. The case member 2 forms an outer shell of the interior air conditioning unit 1, and houses constituent devices of the interior air conditioning unit 1 therein. This case member 2 defines an air passage through which air is blown into the passenger compartment of the vehicle.

[0021]An interior / exterior air switching box 3 is installed in...

second embodiment

[0081]Next, a second embodiment of the present invention will be described hereafter, referring to FIGS. 5-7. Elements that are substantially the same as or equivalent to those in the first embodiment have the same reference numerals as in the first embodiment, and are not described again. FIG. 5 is a schematic diagram showing an entire construction of a refrigerant cycle system according to the second embodiment, which is applied to a vehicular air conditioning system. The refrigerant cycle system 10 according to the second embodiment is configured as a heat pump refrigeration cycle that can be switched between a cooling operation mode and a heating operation mode.

[0082]As shown in FIG. 5, in the second embodiment, a heater core 6 is arranged in a case member 2 of an interior air conditioning unit 1. The heater core 6 is one of the constituent devices that constitute the refrigerant cycle system 10. The heater core 6 functions as a use-side heat exchanger, which heats the air that ...

third embodiment

[0112]Next, a third embodiment of the present invention will be described hereafter. Elements that are substantially the same as or equivalent to those in the first and second embodiments have the same reference numerals as in the first and second embodiments, and are not described again.

[0113]In the above-described second embodiment, a certain control characteristic is selected in accordance with the operation mode, and the temperature of the electric motor 11a is calculated and detected from the detection value of the inverter unit 19, on the basis of the selected control characteristic. In contrast, in the third embodiment, two or more control characteristics in which the criterion values are different are memorized beforehand in ROM etc. of the air conditioner controller 20. Then, a certain control characteristic is selected from the two or more control characteristics in accordance with a degree of superheat of the refrigerant at the suction side of the electric compressor 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com