Heat pump system

a heat pump and heat exchange technology, applied in heat pumps, heating types, lighting and heating apparatuses, etc., can solve the problems of poor energy efficiency of the unit and diminished comfort, and achieve the effect of preventing the rise of excessive temperature of the aqueous medium more reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Overall Configuration

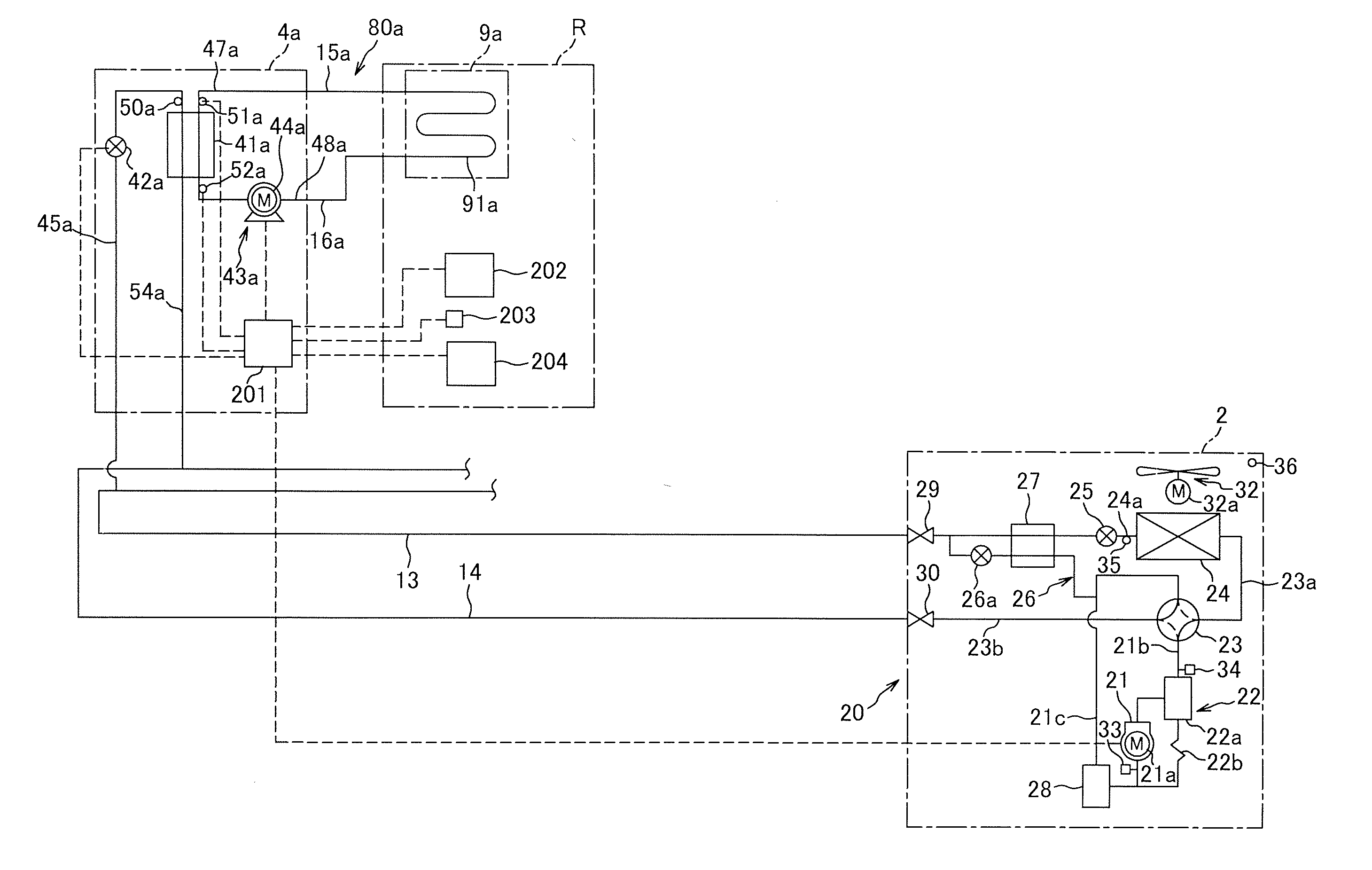

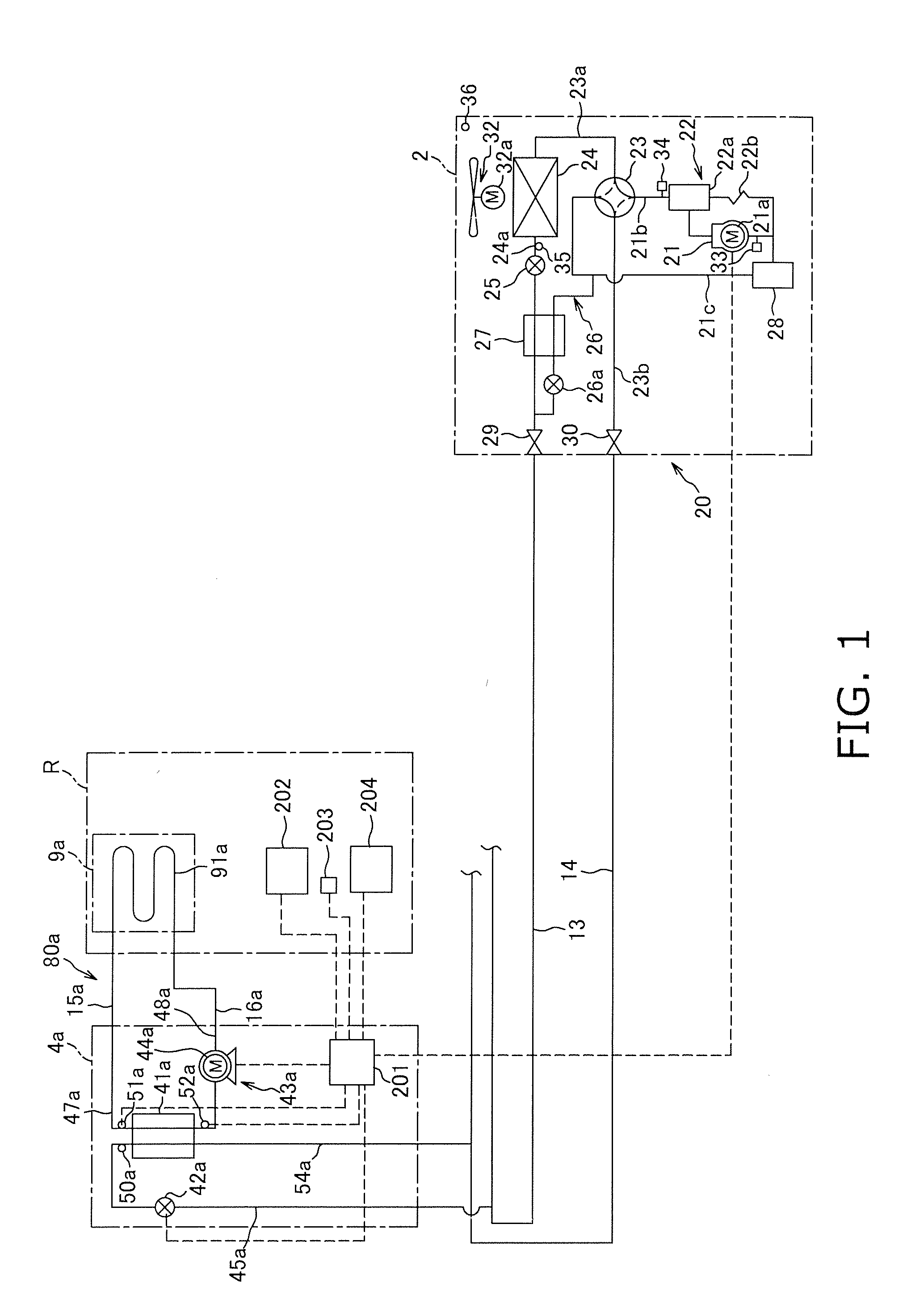

[0019]FIG. 1 is a view showing the general configuration of a heat pump system 1 according to an embodiment of the present invention. A heat pump system 1 is a device capable of utilizing a vapor compression type heat pump cycle to carry out an operation to heat an aqueous medium.

[0020]The heat pump system 1 is primarily provided with a heat source unit 2, a usage unit 4a, a liquid refrigerant communication tube 13, a gas refrigerant communication tube 14, a hot-water air-warming unit 9a, an aqueous medium communication tube 15a, and an aqueous medium communication tube 16a. The heat source unit 2 and the usage unit 4a are connected via the refrigerant communication tubes 13, 14, and thereby constitute a heat-source-side refrigerant circuit 20, while the usage unit 4a and the hot-water air-warming unit 9a are connected via the aqueous medium communication tubes 15a, 16a, and thereby constitute an aqueous medium circuit 80a. HFC-410A, which is a type of HFC-based...

modified examples

(A)

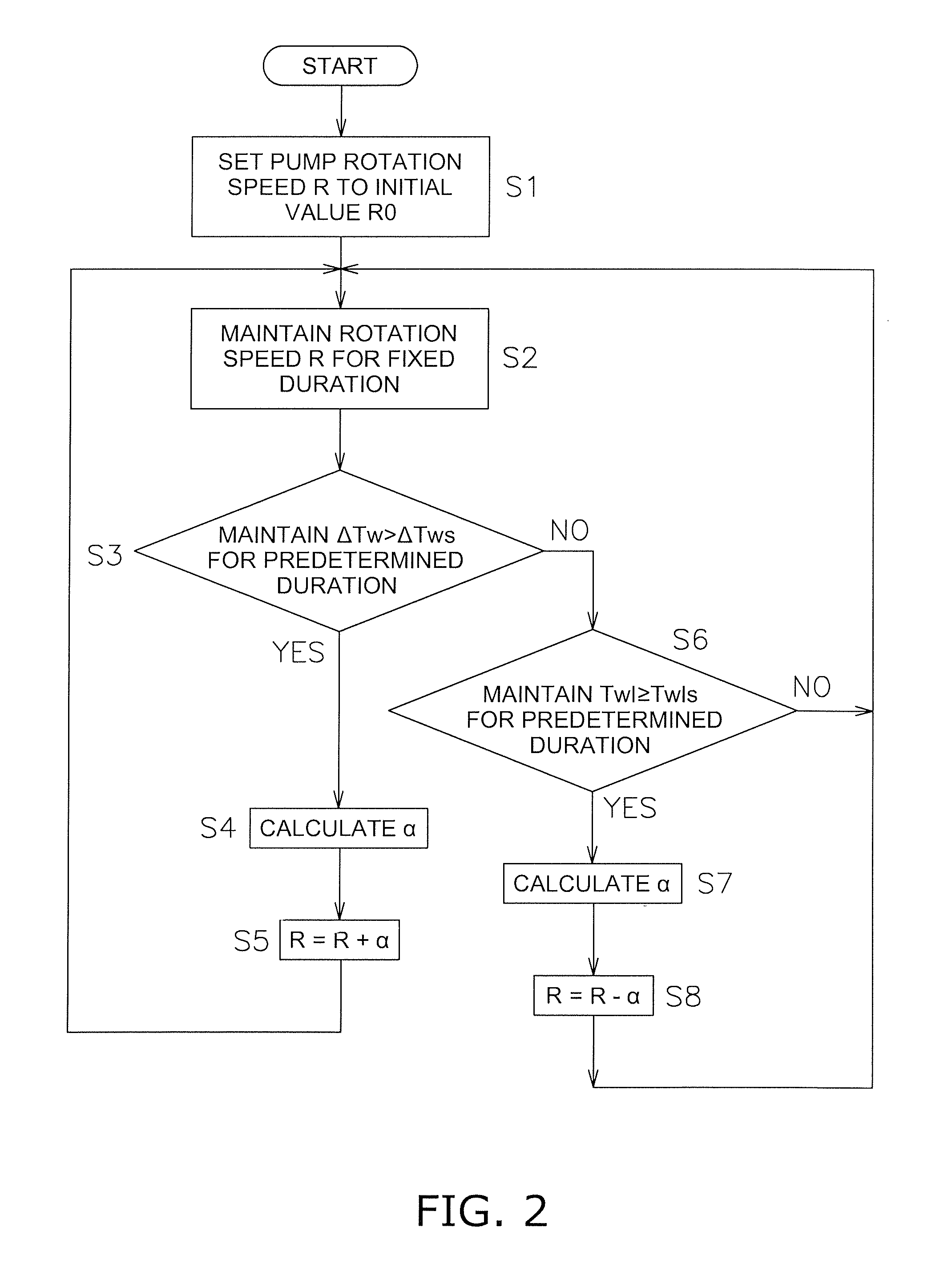

[0110]In the aforedescribed embodiment, in order to aid in understanding of the invention, an example of a single usage unit 4a furnished on the usage side was depicted as one example of the heat pump system 1 of the present invention, but the present invention is not limited thereto, and it is possible for another usage unit (an indoor air conditioning unit or the like) to be connected in parallel with the usage unit 4a to the liquid refrigerant communication tube 13 and the gas refrigerant communication tube 14. In this case as well, by carrying out the operation control of the aforedescribed embodiment, excessive temperature rise of the aqueous medium can be reliably prevented, even in a case of a decrease in load on the usage-side heat exchanger 41a.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com