Synthetic Lubricating Oil

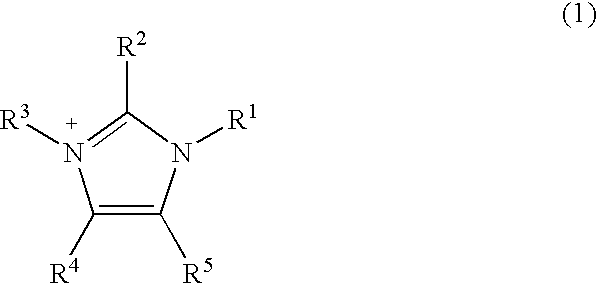

a technology ionic liquid, which is applied in the field of synthetic lubricating oil, can solve the problems of insufficient viscosity reduction of ionic liquid comprising this combination of anion, flash ignition or evaporation danger of lubricating oil, etc., and achieves excellent anti-abrasion properties, stable flowability and viscosity characteristics, and stable lubricating properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

[0050]In a flask equipped with a refluxing column were charged 19.1 g (0.10 mol) of 1-ethyl-3-methylimidazolium bromide and 20 ml of water, and further 21.9 g (0.10 mol) of potassium salt of bis(fluorosulfonyl)imide, followed by stirring at 40° C. for 5 hours. After the reaction, 80 ml of methylene chloride was added, followed by well stirring and fractionating. The methylene chloride layer was washed five times each with 40 ml of water, and the methylene chloride layer is concentrated under reduced pressure to give 23.8 g (0.08 mol, yield: 81.8%) of 1-ethyl-3-methylimidazolium bis(fluorosulfonyl)imide.

synthesis example 2

[0051]The same procedure as the above Synthesis example 1 excepting using 20.5 g of 1-methyl-3-propylimidazolium bromide in place of 19.1 g of 1-ethyl-3-methylimidazolium bromide was conducted to give 27.5 g (0.09 mol, yield: 90.1%) of 1-methyl-3-propylimidazolium bis(fluorosulfonyl)imide. Viscosity of this compound was 29 mPa·s (25° C.).

synthesis example 3

[0052]The same procedure as the above Synthesis example 1 excepting using 20.5 g of 1-methyl-3-isopropylimidazolium bromide in place of 19.1 g of 1-ethyl-3-methylimidazolium bromide was conducted to give 27.1 g (0.09 mol, yield: 88.8%) of 1-methyl-3-isopropylimidazolium bis(fluorosulfonyl) imide. Viscosity of this compound was 27 mPa·s (25° C.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com