Device and Method for Improved Pile Casting

a technology of improved pile casting and casting device, which is applied in the direction of bulkheads/piles, construction, foundation engineering, etc., can solve the problems of soil shrinkage, unevenness, and cracks that can be several meters deep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

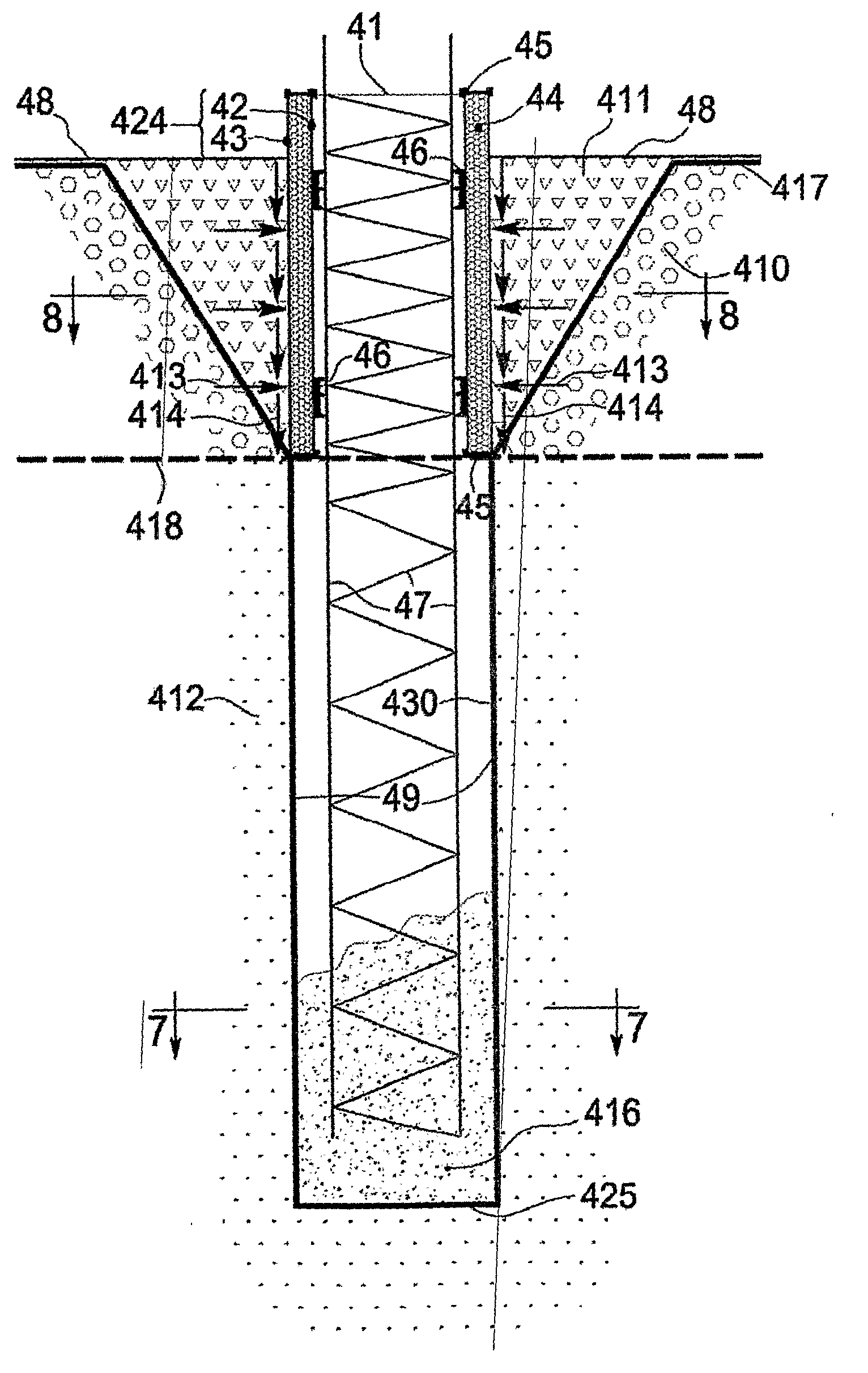

[0034]FIG. 1 is a view depicting some of the elements of this inventive device 11, and should be preferably viewed in conjunction with FIGS. 2, 3, 4, 9 and 11.

[0035]FIG. 1 depicts 12, a relatively thick and rigid inner sleeve having an inner diameter, a thickness, and a length, said thickness could be typically 1 to 5 mm but is not limited to this range. Several of many possible materials for 12 are polypropylene, PVC, HDPE and cardboard, 14 is a filling sleeve of a preferably relatively low density, low elastic modulus, highly deformable material such as a plastic or other foam, of which the widely used low density polystyrene foam (Styrofoam™) is a typical example, an outer sleeve 13 is of a relatively thin and preferably smooth, low friction coefficient material for sliding on 14, each of sleeves 12, 13, 14 having substantially the same length and two extremities, sleeve 12 is encompassed by sleeve 14 and sleeve 14 is encompassed by sleeve 13. Two sealing rings 15, a bottom one (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com