Method for filling and sealing liquid content in spouted pouch and apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

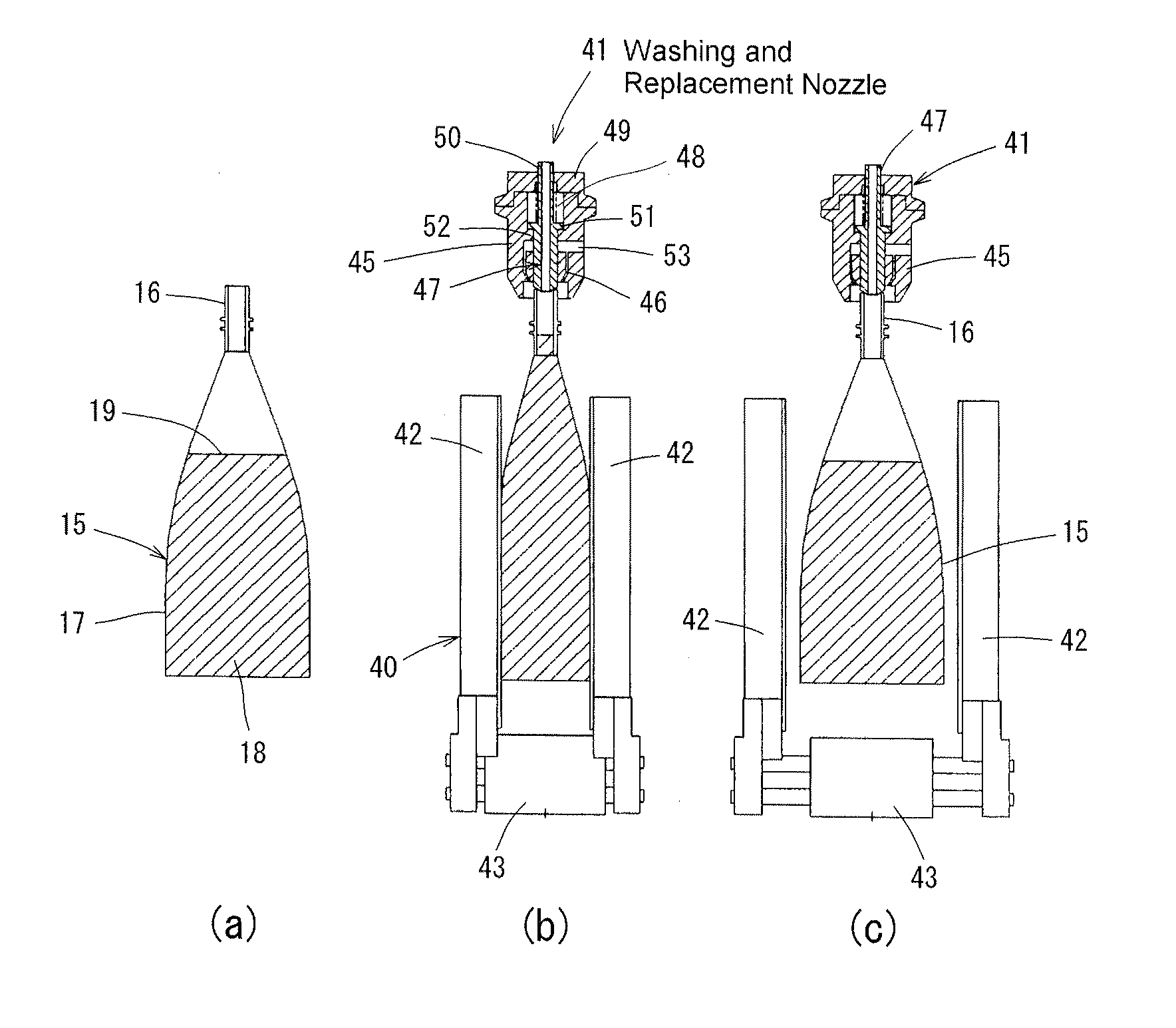

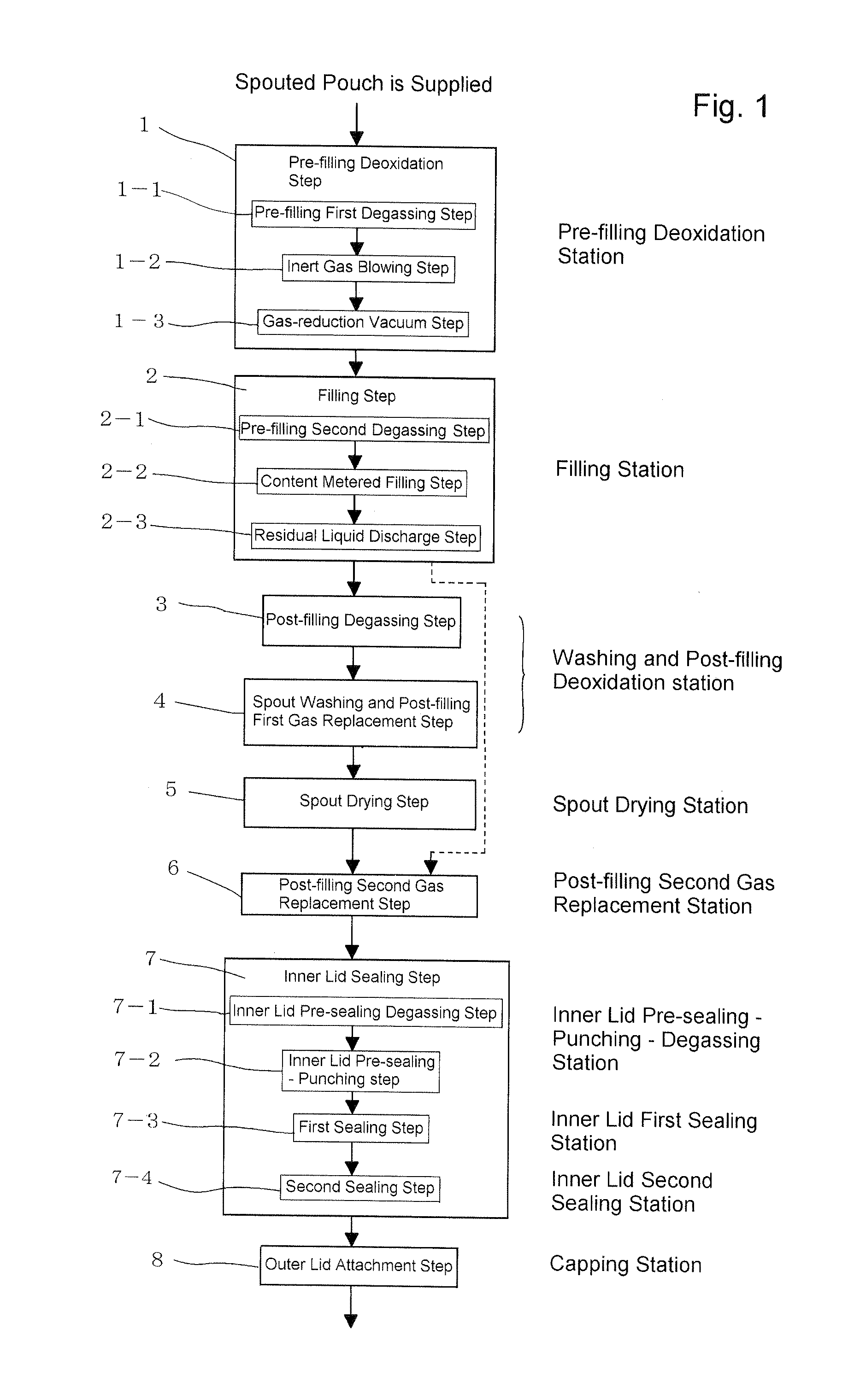

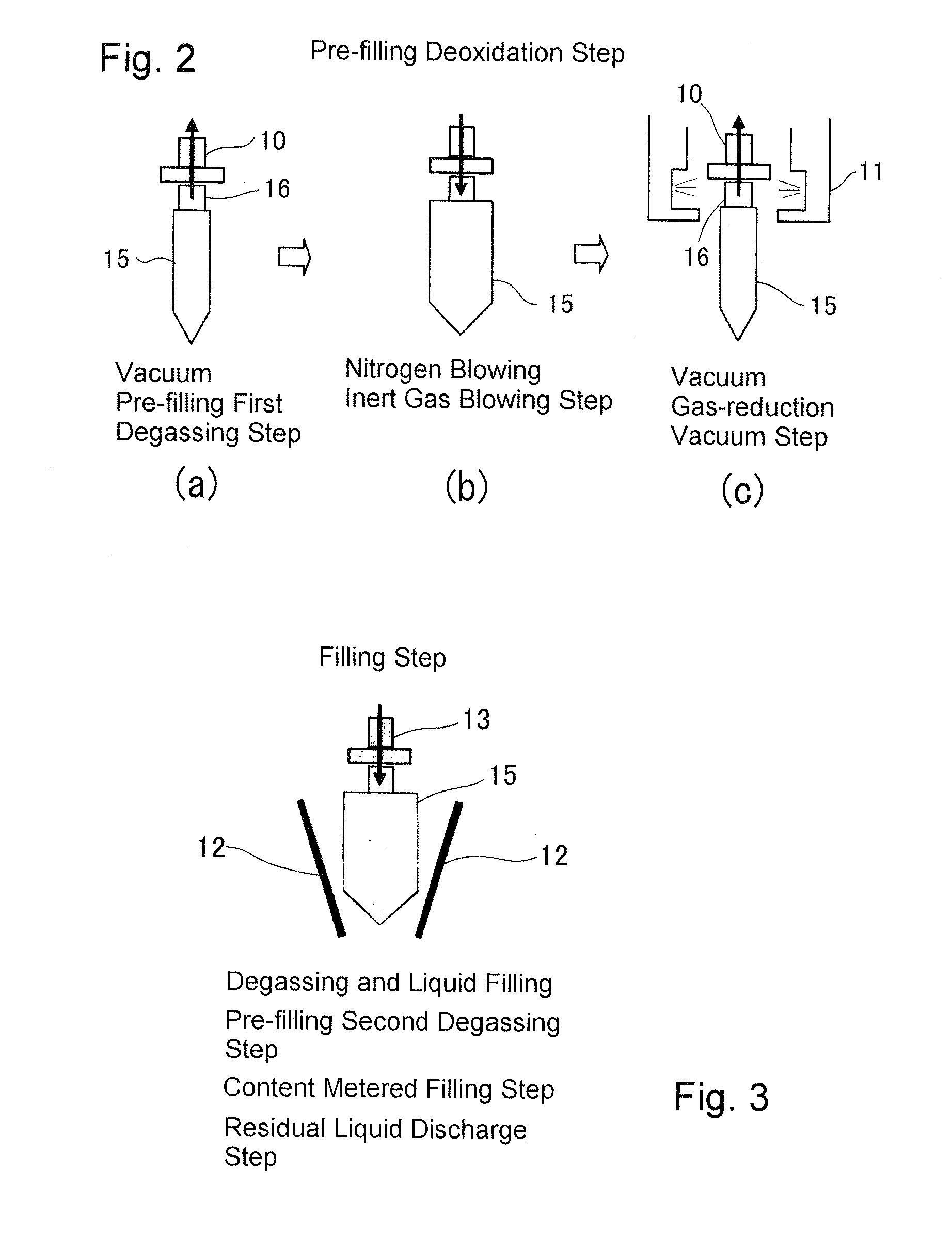

Method used

Image

Examples

examples

[0100]The following test was conducted to confirm the effect of deoxidation attained by providing the pre-filling deoxidation step.

[0101]As shown in Table 1, the test was divided into a test in which of the first degassing step, inert gas blowing step, and degassing step of the pre-filling deoxidation step, only the first degassing step and the inert gas blowing step were implemented, and the degassing step was not performed (No. 1 and No. 2), a test in which the degassing step was performed without a nitrogen atmosphere (No. 3), and a test in which the degassing step was performed under a nitrogen atmosphere (No. 4), the content of air, oxygen concentration, and amount of oxygen were measured after sealing, and the replacement ratio was found. The degassing was carried out for 0.5 sec for all the samples, and nitrogen was blown for 0.03 sec only in No. 1 and for 0.14 sec in other tests. The results are shown in Table 1. Data shown in Table 1 represent the measurement values obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com