Stirring apparatus and method

a technology of viscous media and apparatus, which is applied in the direction of process and machine control, electrical programme control, instruments, etc., can solve the problems of not being able to rotate the fluid in the mixing receptacle, not being able to meet the needs of mixing viscous fluid, so as to avoid sedimentation, avoid clumping, and avoid adverse effects of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

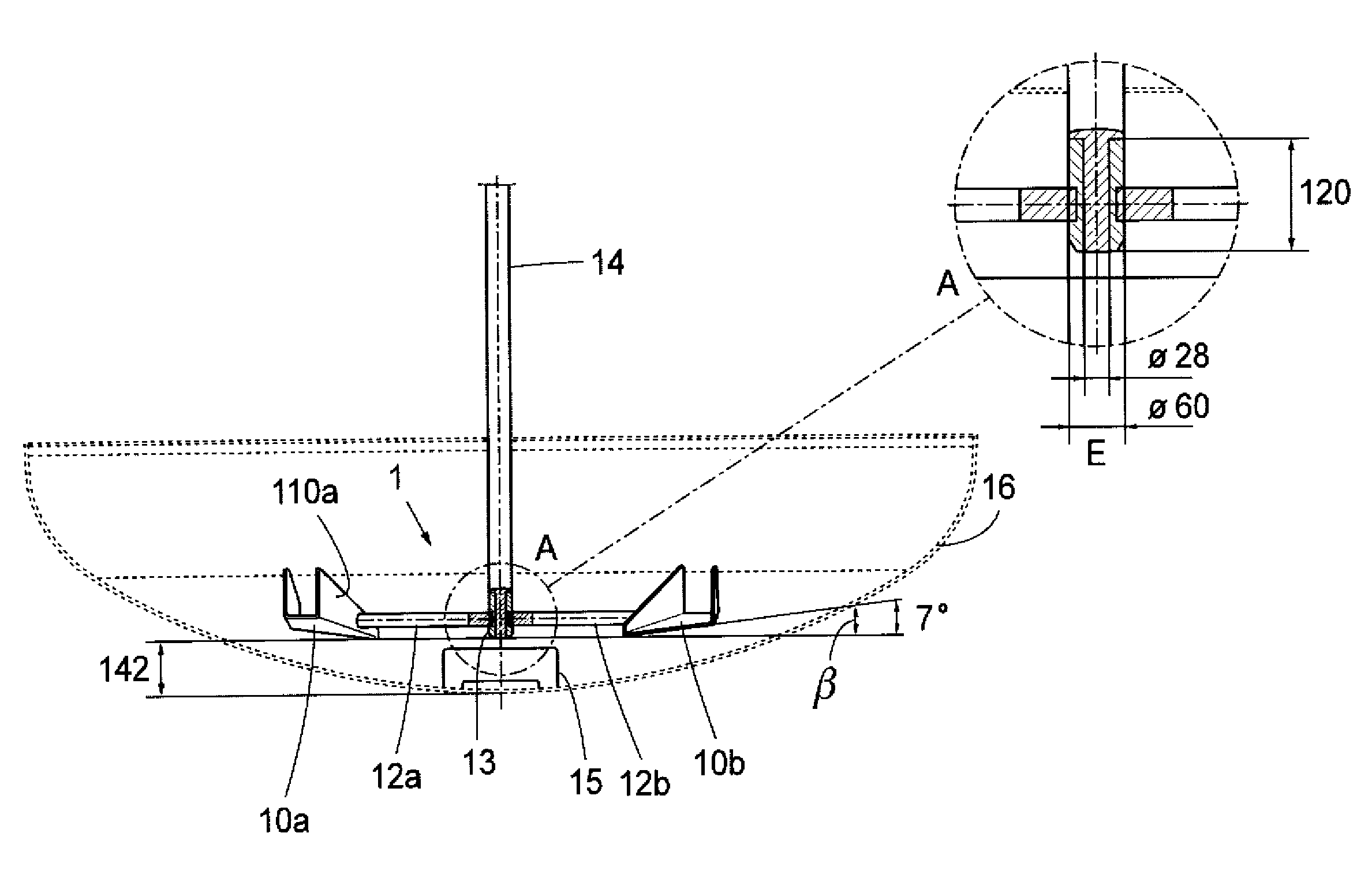

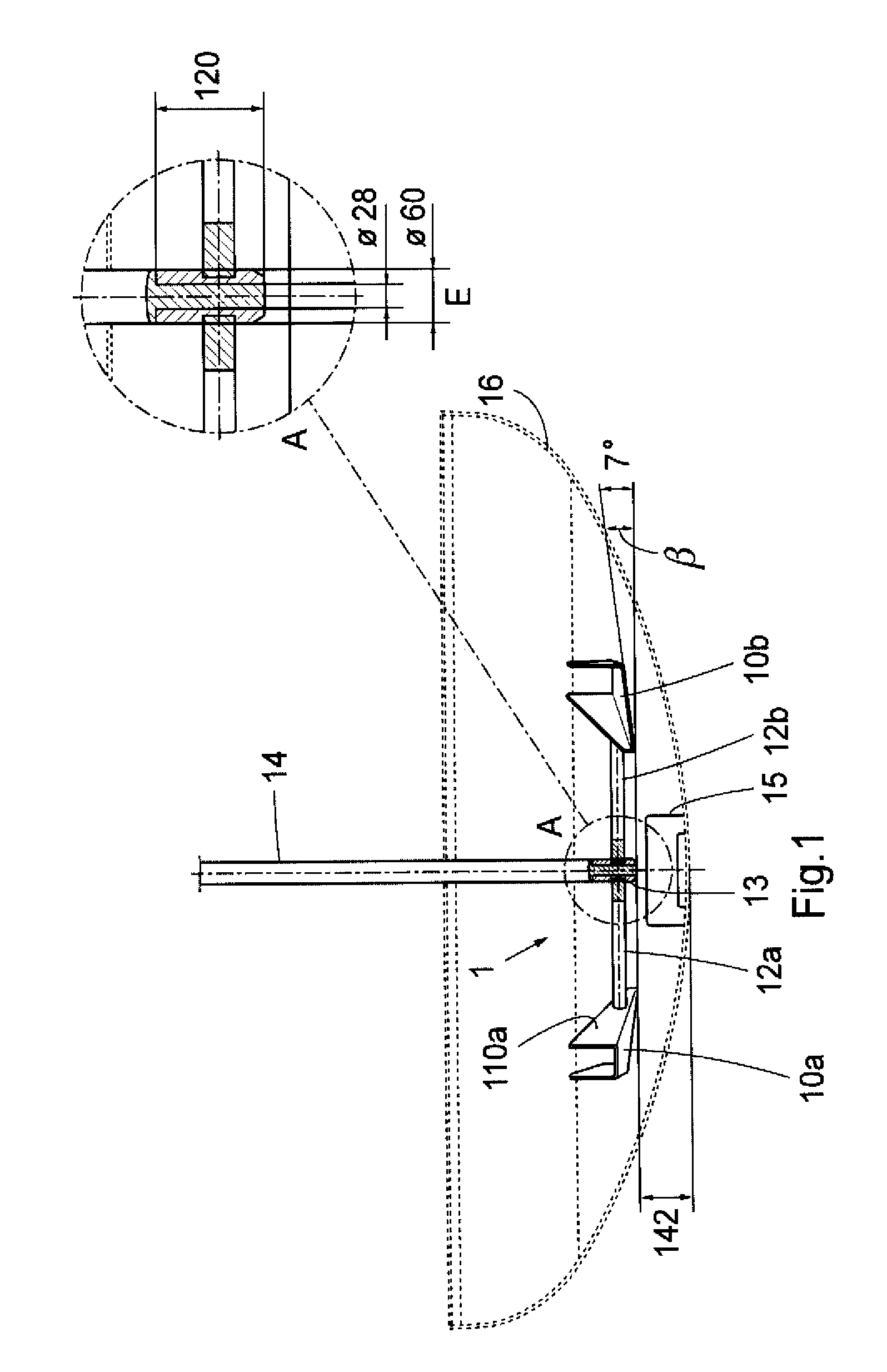

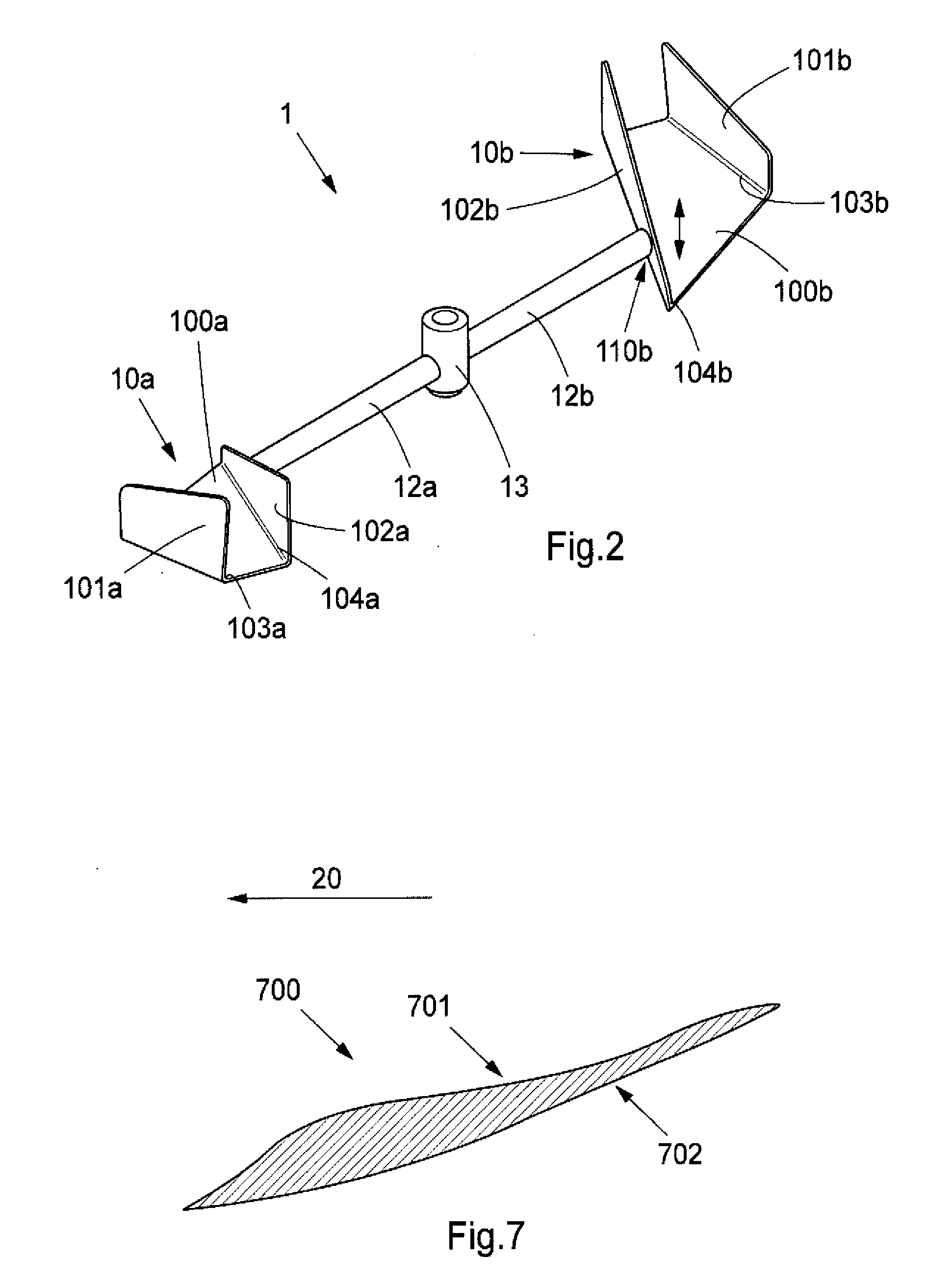

[0081]A stirring apparatus according to the attached Figures was used for stirring a viscous medium.

[0082]The requirements specifically demanded of the apparatus were the following in particular:[0083]The mixing mechanism should be able to mix a creamy substance, such as soured milk or yoghurt, with fruit particles.

[0084]Test Data:[0085]Tank diameter: 3000 mm[0086]Tank height: 4000 mm[0087]Tank content: 20 m3 (20 000 liters)[0088]Medium: fruit cream[0089]Viscosity: 15000 CentiStokes (cSt)[0090]Density: 1[0091]Temperature: 10 DEG C.[0092]Dimensions of stirring elements: according to the attached Figures and related description above.[0093]Drive motor: 2.2 kW[0094]Stirring speed: 200 rpm, respectively.

[0095]Result: An excellent mixing effect was achieved after a mixing time of 20 minutes with low power requirement and operating costs.

[0096]As used herein, the singular forms “a”, “an” and “the” are intended to include the plural forms as well, unless expressly stated otherwise. It will...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radial slant angle | aaaaa | aaaaa |

| radial slant angle | aaaaa | aaaaa |

| circumferential velocities | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com