Susceptor, vapor phase growth apparatus, and method of manufacturing epitaxial wafer

a technology of vapor phase growth and substrate, which is applied in the direction of polycrystalline material growth, chemically reactive gas growth, crystal growth process, etc., can solve the problem of difficulty in raising the surface use rate, and achieve good crystallinity and reduce the defect of semiconductor elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

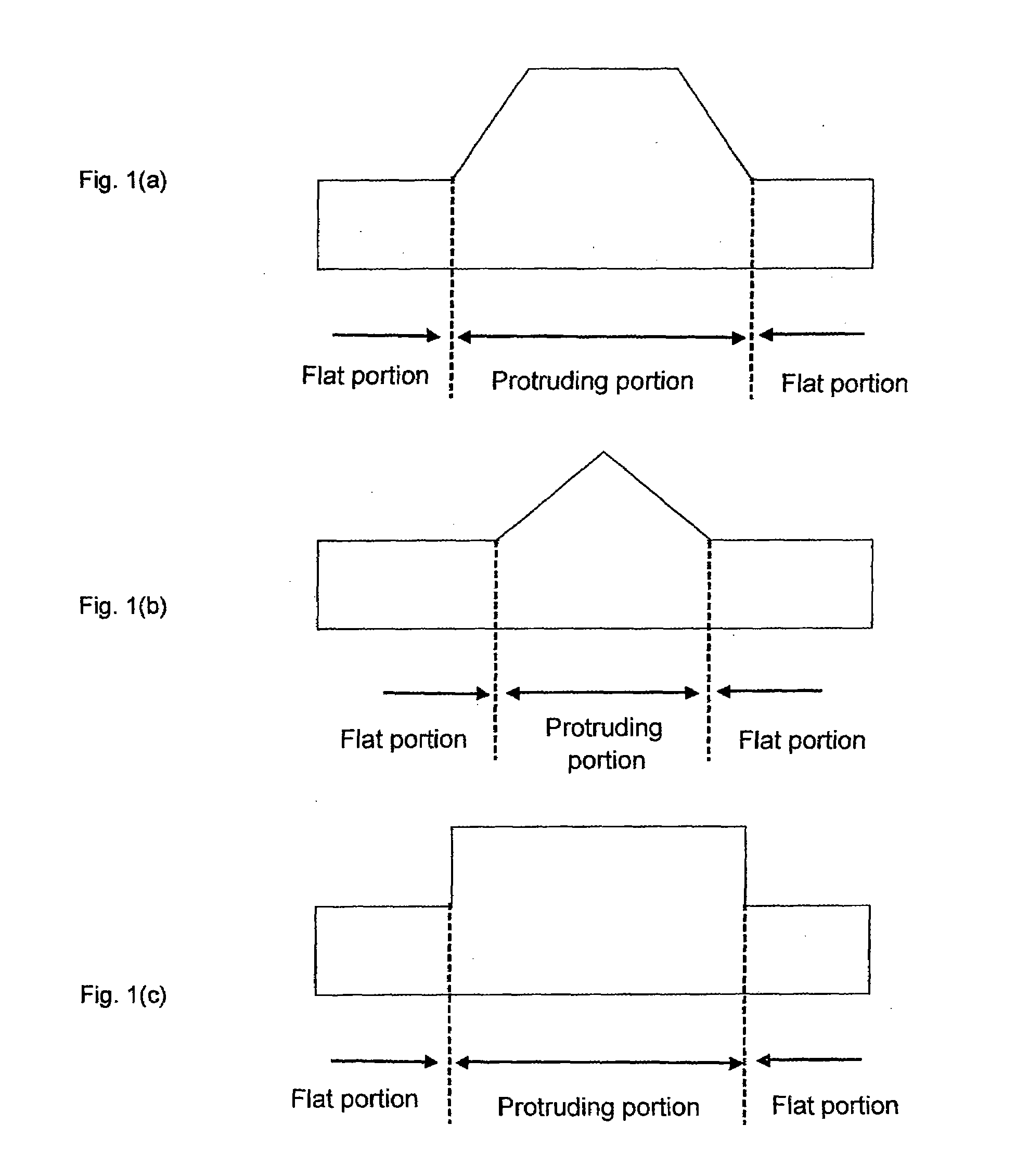

[0075]A 300 mm semiconductor wafer on which an epitaxial layer is to be formed on the (100) face thereof was placed on a susceptor that had been disposed within the reaction chamber of a vapor phase growth apparatus and that was equipped with protruding portions in the 85° to 95°, 175° to 185°, 265° to 275°, and 355° to 5° portions thereof when the position opposite the wafer notch (notch-opposing part) of the lateral wall of the counterbored groove was aligned with 0°.

[0076]An epitaxial film was grown by vapor phase epitaxy on the surface of the semiconductor wafer placed on the susceptor. The epitaxial growth process will be described in detail below.

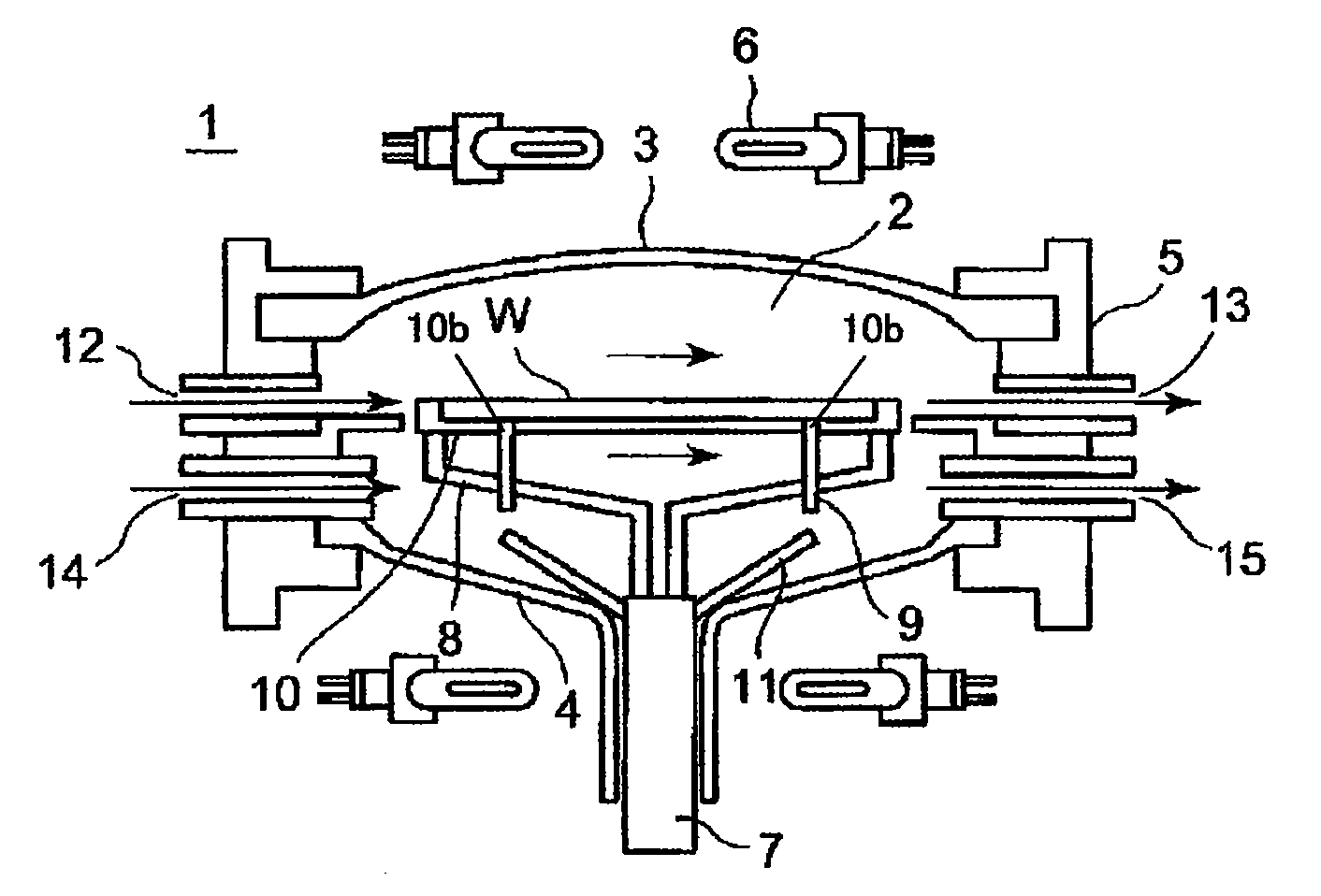

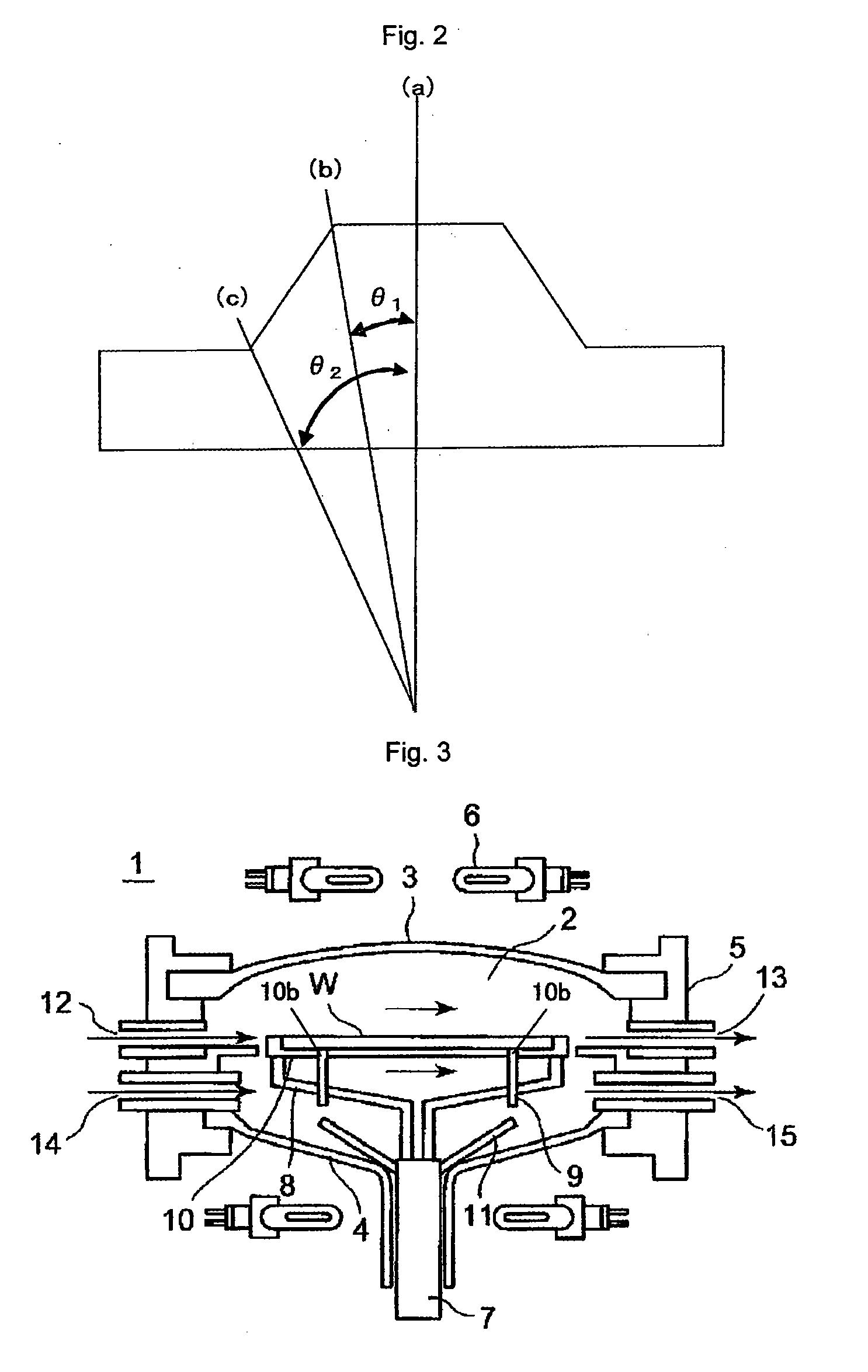

[0077]The vapor phase epitaxial growth apparatus employed comprised a chamber above and below which heaters were disposed, and in the center of which was horizontally disposed a susceptor that was capable of holding a single wafer and that was round when viewed from above.

[0078]An upper counterbored portion (annular difference in heig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle θ1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com