Hydrogen gas-cooling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

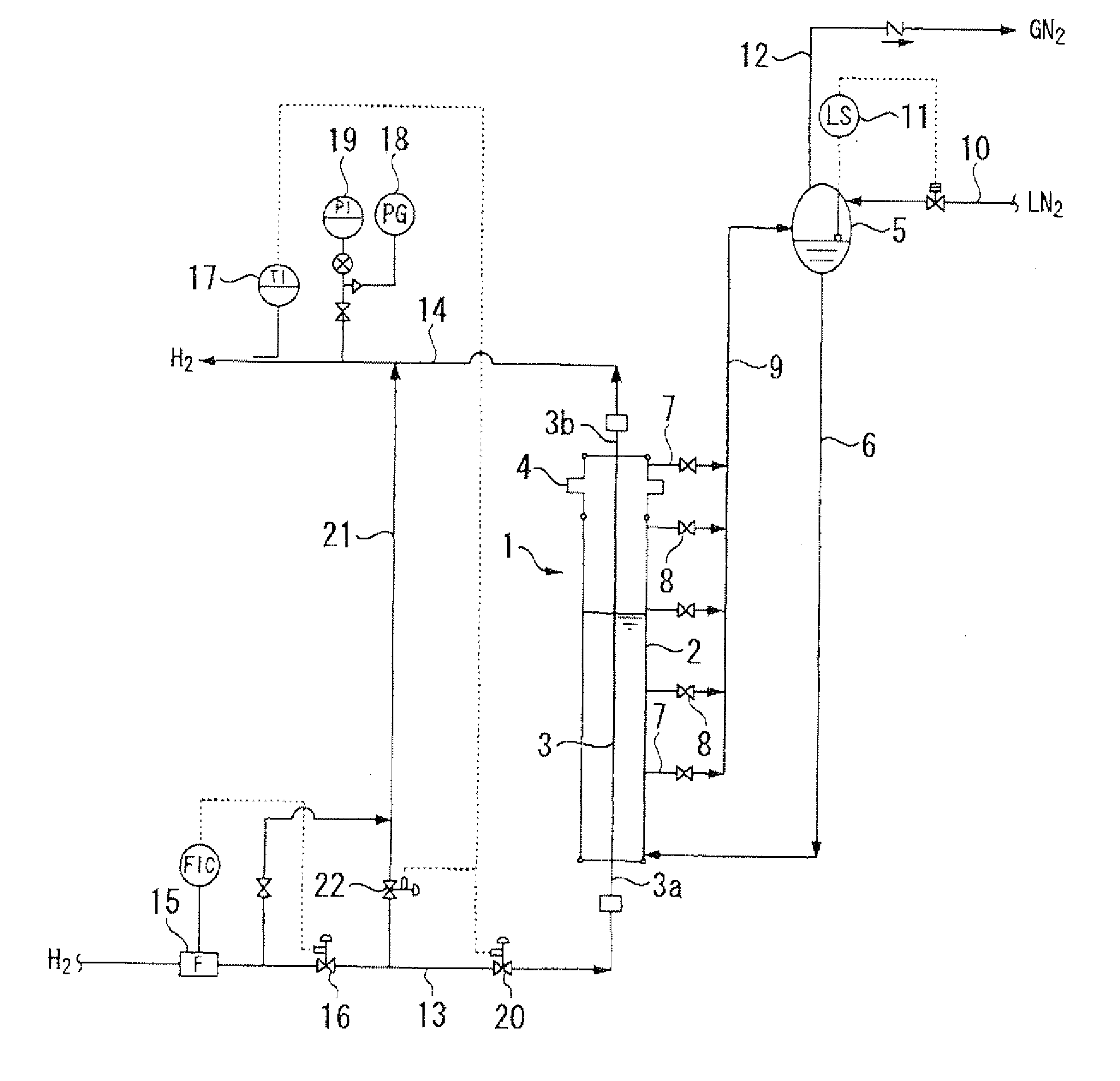

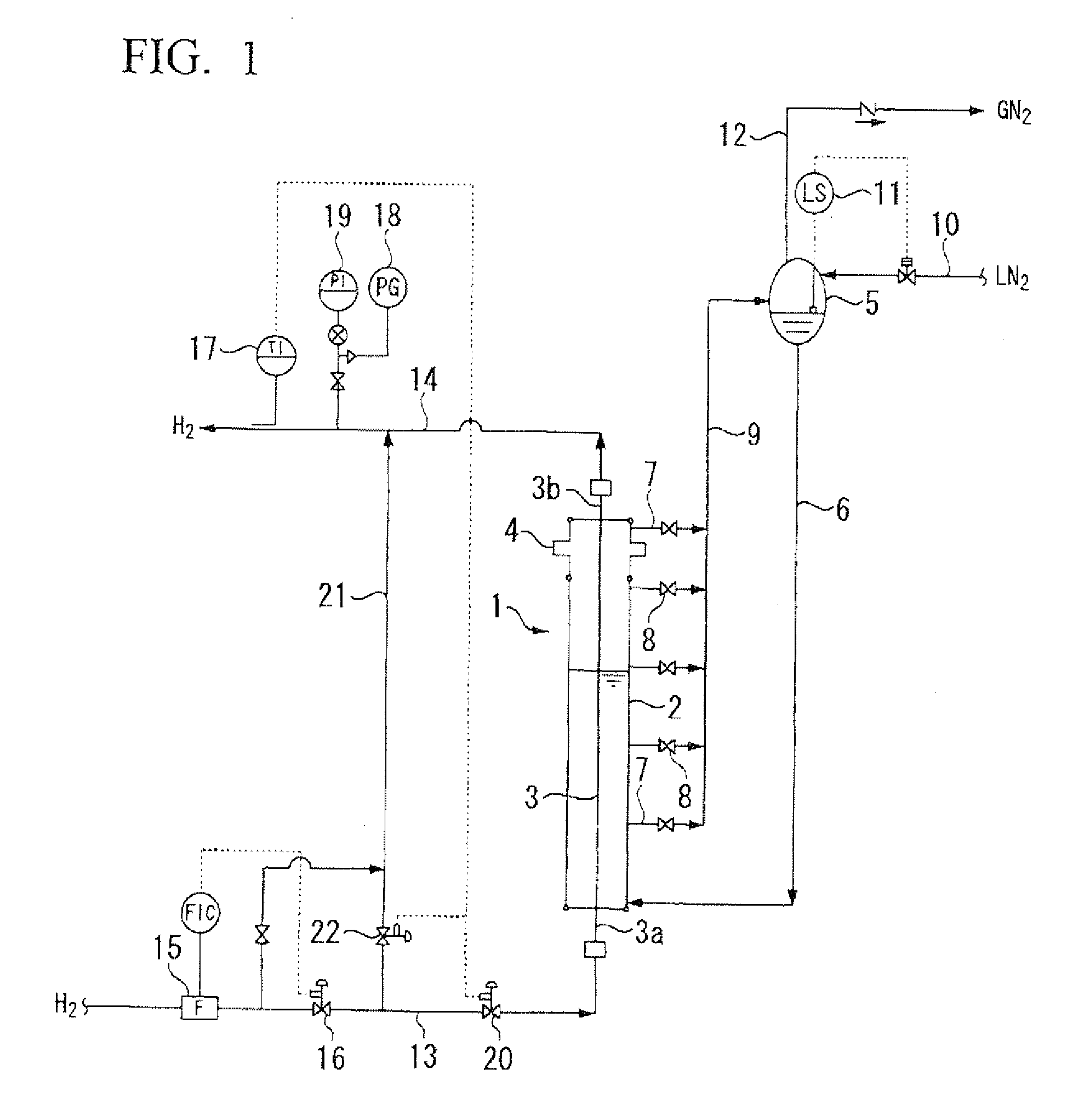

[0026]FIG. 1 represents an example of the hydrogen-cooling device of the present invention. In FIG. 1, the reference symbol 1 represents the heat exchanger. This heat exchanger 1 has the double pipe structure formed of the straight pipe-shaped outer pipe 2 and the straight pipe-shaped inner pipe 3 that is coaxially provided within the outer pipe 2.

[0027]This heat exchanger 1 is positioned in the sanding state in which the axes of the outer pipe 2 and the inner pipe 3 are arranged vertically or in the direction that is slightly tilted from the vertical direction.

[0028]The outer pipe 2 has the function of storing the liquefied gas therein which acts as a refrigerant such as liquid nitrogen, and is formed of a stainless steal with an inner diameter of 40-60 mm, an outer diameter of 45-80 mm, and a length of 500-2,000 mm The upper pact of his outer pipe 2 forms the bellows 4 that can elongate and contract in the longitudinal direction. Herein, the position of this bellows 4 is not limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com