Interchangeable electric motor for powered garden implements

a technology of electric motors and garden implements, which is applied in the direction of cutting implements, dynamo-electric machines, applications, etc., can solve the problems of lack of common parts, different models of electric motor powered implements, and very little sales of electrically powered implements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

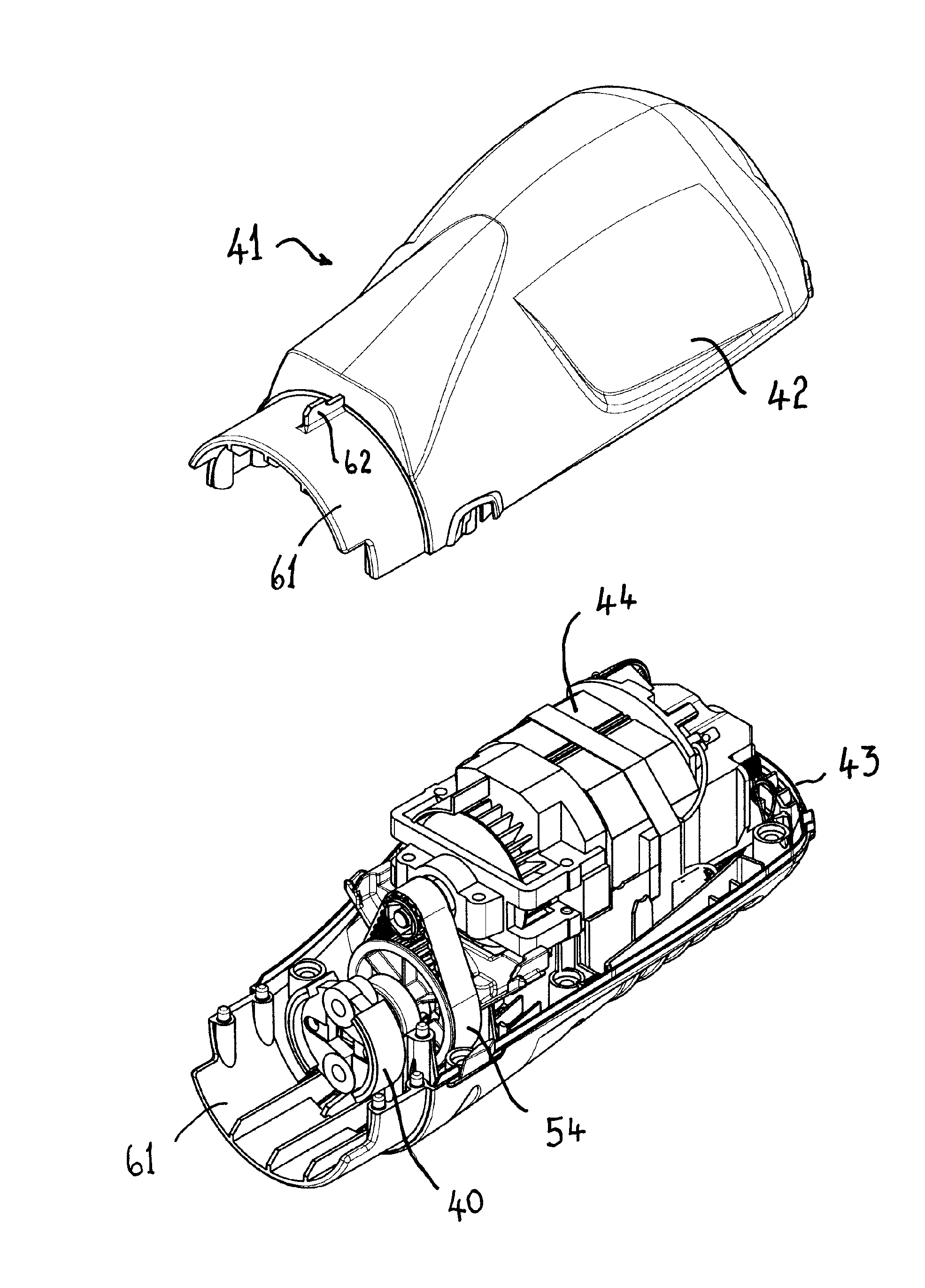

Image

Examples

Embodiment Construction

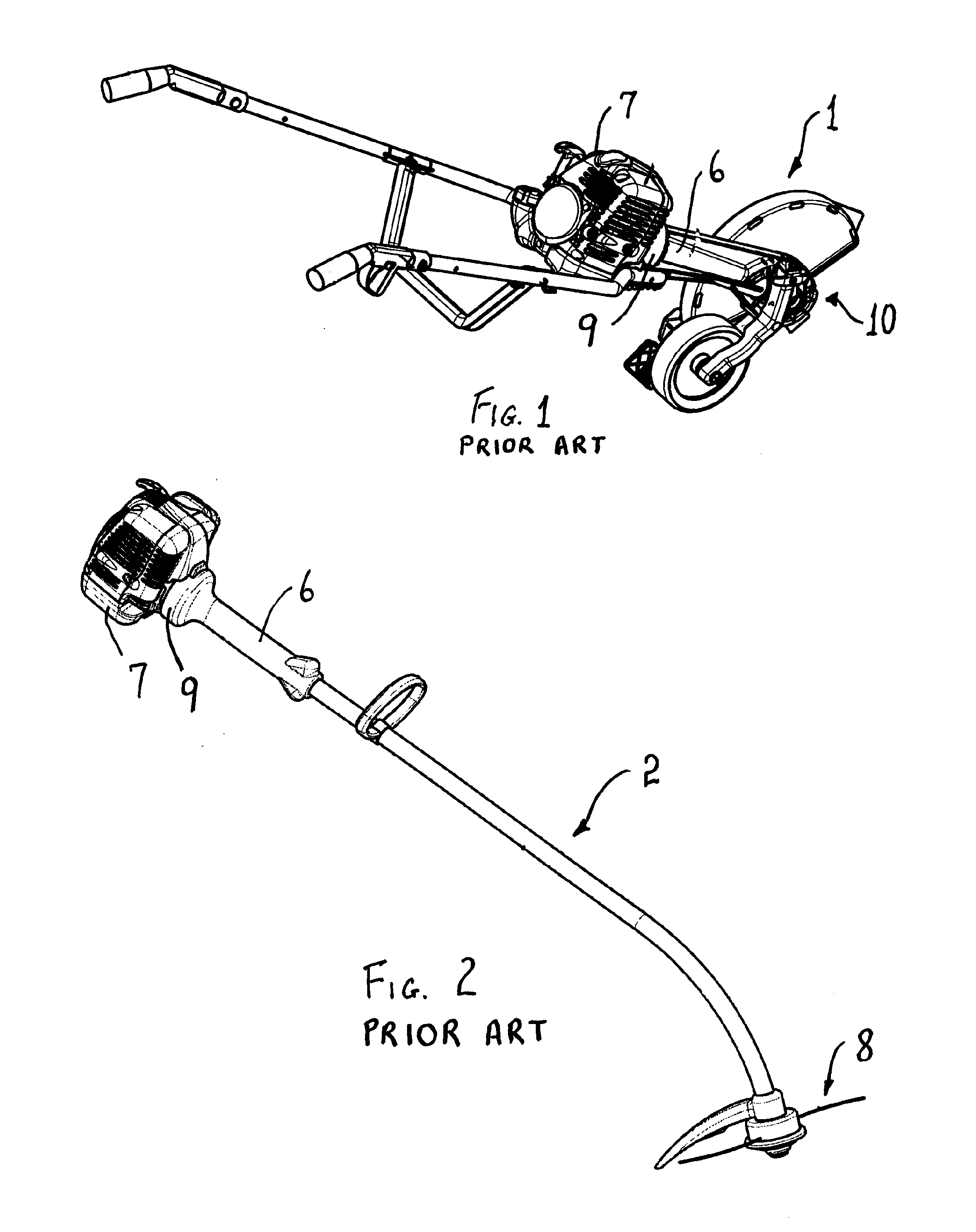

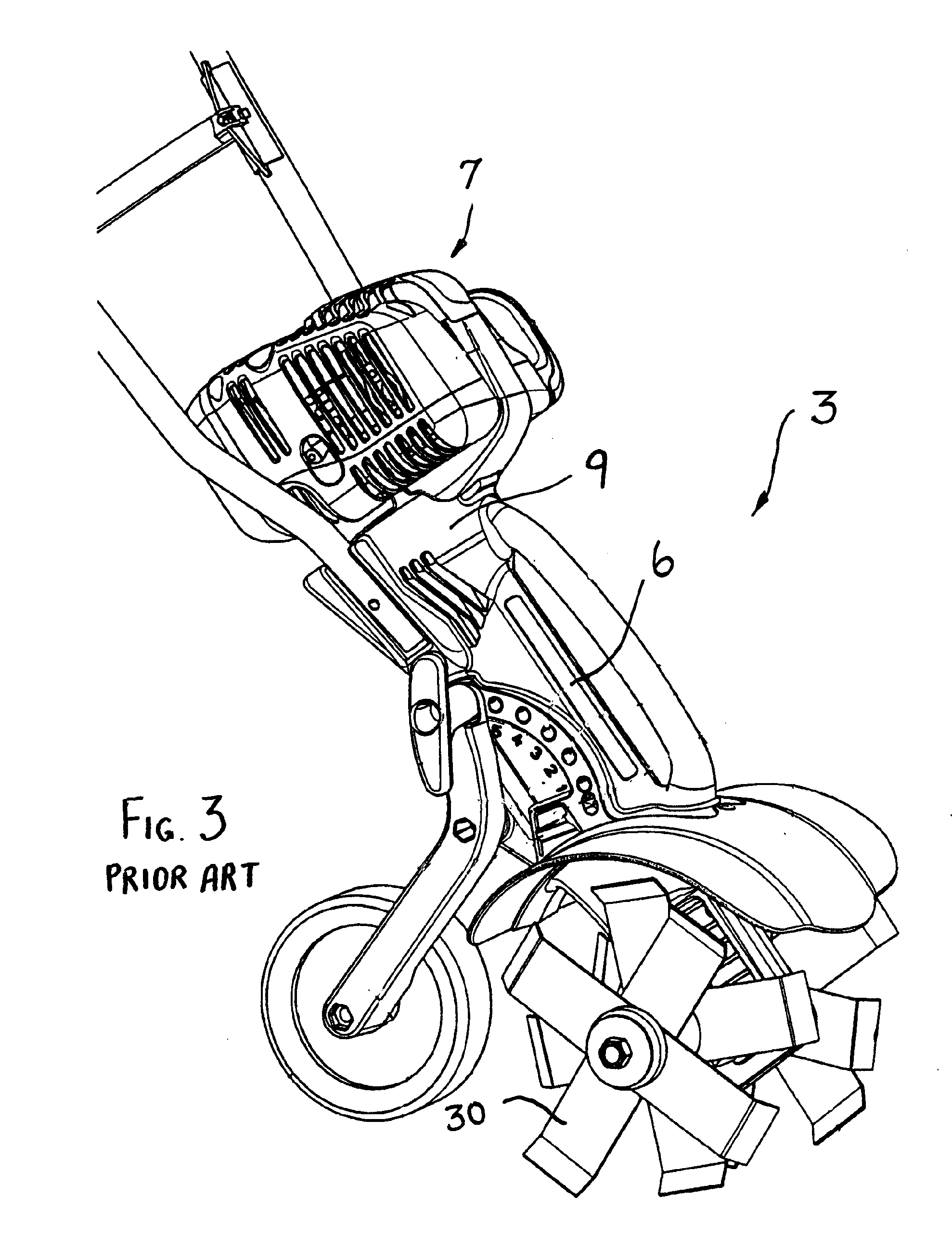

[0020]A prior art edger 1 having a frame 6 and an internal combustion engine unit 7 is illustrated in FIG. 1. The cutting blades (not visible in FIG. 1) of the edger 1 rotate at an ideal speed of 2,000-2,200 rpm and thus the speed reduction gearing which is present in the hub 10 is typically a 3.5 to 1 speed reduction. For an electric motor model of the edger 1 incorporating a universal motor, it is necessary to use a different arrangement of reduction gears in the hub 10, in this case having a reduction of approximately 7 to 1, otherwise the blade speed is too high. Conversely, in the event that a 2 pole induction motor is used as the power plant, again the gear arrangements within the hub 10 must be changed so as to provide approximately a 2.5 to 1 speed increase.

[0021]Similarly, a trimmer 2 having a frame 6 and being powered by an internal combustion engine unit 7 is illustrated in FIG. 2. The engine unit 7 includes a clutch (not illustrated) and mates with a shroud locking ring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| rotational speed | aaaaa | aaaaa |

| electric | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com